Foreign customer case | Jungheinrich creates automation solutions for August Weckermann

January 06, 2023• Automated Spare Parts Warehouse (AS/RS) As the core of optimizing internal logistics

• Energy saving、Future-oriented and sustainable development

• Yonghengli Warehouse Management SystemWMSFlexible docking with existing systems

Hamburg/Eisenbach——August Weckermann It's turning、Traditional quality manufacturer of milled and precision parts,Is being located atEisenbach, Baden-WürttembergThe company expanded its new production base.。Here,The company hopes to passIntegration of modern energy concepts,Complete direction“Green Factory”The transformation。For long-term optimization of material flow,August Weckermann Jungheinrich Automation Spare Parts Warehouse (AS/RS)。The project is scheduled for one-stop delivery in the summer of 2023.。

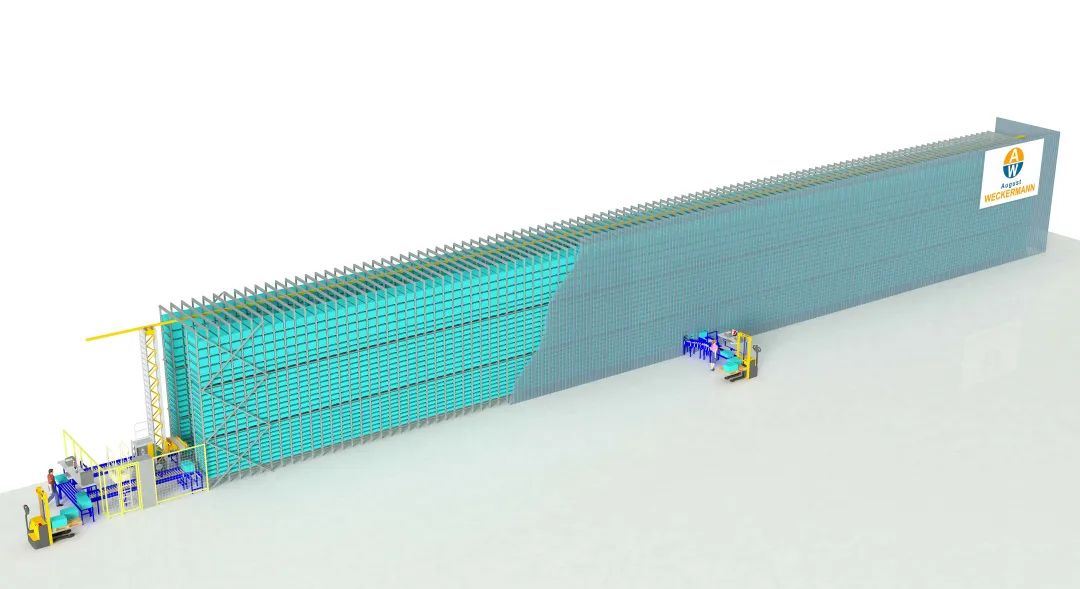

Single aisle bin stacker warehouse hasOver 10,000 storage bit,And equipped with a picking workstation。This60 x 4.2 x 7.3-meter warehouse,The future willOperate five days a week。Even single shift operation,Jungheinrich's automation solutions have also proven to be efficient options.。“Solutions we offer,Regardless of the processing speed、Capacity,Or in terms of energy efficiency.,”Eternal powerASRSProject ManagerClaus BodeSay。The delivery scope of the total solution also includes Jungheinrich Warehouse Management System.(WMS),The system will be integrated into the August Weckermann ExistingITIn the environment。WMSFlexible connectivity to existing systems is essential for cooperation。“Eternal Force shows us various scenarios of interface connection in advance.,And gave us flexible and open-ended advice.,”August Weckermann The project manager ofJens SchulerExplained。“Final,We are very optimistic about the Jungheinrich Warehouse Management System, which can comprehensively manage the warehouse.(WMS)。”

For the time-honoredAugust WeckermannFor the company,Previously, automated warehouse lifts were used to move parts only at points on the production links,The all-new bin stacker represents an important step towards automation,Jungheinrich is the preferred partner to assist in this step.。“Jungheinrich offers the right automation solutions across its portfolio for companies of different sizes。We customize a one-stop intralogistics solution based on customer needs。”BodeEmphasize that。