Site Report | Successful Application of W 380 CR Foamed Asphalt Cold In-place Recycling Technology in Wenbei Road, Haidian District, Beijing

December 06, 2022Of the party“The 18th CPC National Congress”Since,The state has promoted the construction of ecological civilization to the height of development strategy.,Green environmental protection and resource recycling have become an important part of high-quality development.。

Realized in the field of transportation“Comprehensive Transportation、Intelligent transportation、Green traffic、Safe traffic”It has become an important practice in the construction of national ecological civilization.,Haidian District is a demonstration area of science, technology and environmental protection in Beijing.,It is naturally at the forefront of society in the field of low-carbon environmental protection.。

Recently,Wittgen W 380 CR Cold In-Place Reclaimer and Vogler Paver、The road cold recycling unit composed of Hummer rollers successfully carried out in-situ cold recycling of foamed asphalt in Wenbei Road, Haidian District, Beijing.,It fully embodies low carbon.、Environmental protection、Demonstration effect of saving resources。

01Project overview

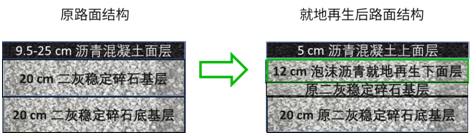

Wenbei Road is a traffic artery connecting Haidian District and Changping District.,The width of the road surface varies.,The pavement width of some sections is 11 m,There are also some sections with a pavement width of 16 m,Thickness of surface course of most road sections 11 cm。The traffic time is long,In addition, the effect of traffic load for many years,The fatigue disease of the original pavement is serious.,The upper part of the base has a certain degree of disease.,However, the base strength is relatively stable.。

The original elevation is unchanged.、The construction period is shortened、The principle of maximizing the use of resources,The owner, Beijing Haidian District Municipal Service Group Co., Ltd., decided to adopt the foam asphalt cold recycling technology based on synchronous paving to repair Wenbei Road.。

The construction party, Beijing Lixin Road Maintenance Engineering Co., Ltd., first carried out 5. cm Milling and planing,Then to the lower 12 cm In-situ regeneration of foamed asphalt on the structural layer,Final resurfacing 5 cm Modified asphalt concrete,And ensure that the final elevation remains unchanged.。

For individual road sections with serious diseases——Deflection values exceed 50 (0.01 mm),Cold in-place recycling of foamed asphalt as per 20 cm The thickness proceeds。

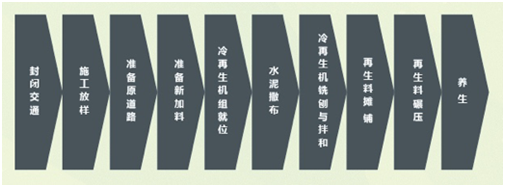

02Construction process flow

Make use of W 380 CR The cold recycling equipment cuts and breaks the original asphalt pavement and completes the addition and mixing of the foamed asphalt and the cement,Creating a new cold recycled mixture,The new cold recycled mix is then delivered to the Paver hopper,Pave directly by Paver,The paved mixture is efficiently compacted by a Hummer roller to form a brand-new regenerated structural layer.。

Based on synchronous paving W 380 CR Workflow of Foamed Asphalt Cold Recycling Fleet

Construction steps of cold in-place recycling project

Wittgen W 380 CR The local cold Recycling Machine is equipped with 708 kw An efficient engine,Strong milling and mixing capabilities,Working width up to 3.8 m,Efficient regeneration of a lane at one time。

The old asphalt materials are milled and transported to the subsequent Vogler Paver.,Material inhomogeneity is eliminated,The thickness control of the regeneration layer is more accurate,And that flatness is bet,Can fully meet the technical requirements of the lower surface layer of the high-grade road。

In the following compaction link,The construction side also adopted a new model of Hummer large double-wheel roller which meets the fourth national emission standard. HD 138i,Make the construction process more low-carbon and environmentally friendly。

The vibration frequency of this new type of roller is 20% higher than that of the old model%,More efficient compaction,Up to 15-20%。The Road Roller also carried HAMMTRONIC Intelligent compaction control system,Walking speed by presetting pressure,Intelligent control functions such as slow start, slow stop and automatic vibration,Resulting in more uniform compaction。

Especially when working at night.,The artificial operation error can be well avoid,Construction is safer,Therefore, the construction efficiency and quality have always maintained a high level.。(Click to learn about the new generation of Hummer HD 138i More Performance Features of Large Double Steel Wheel Roller)

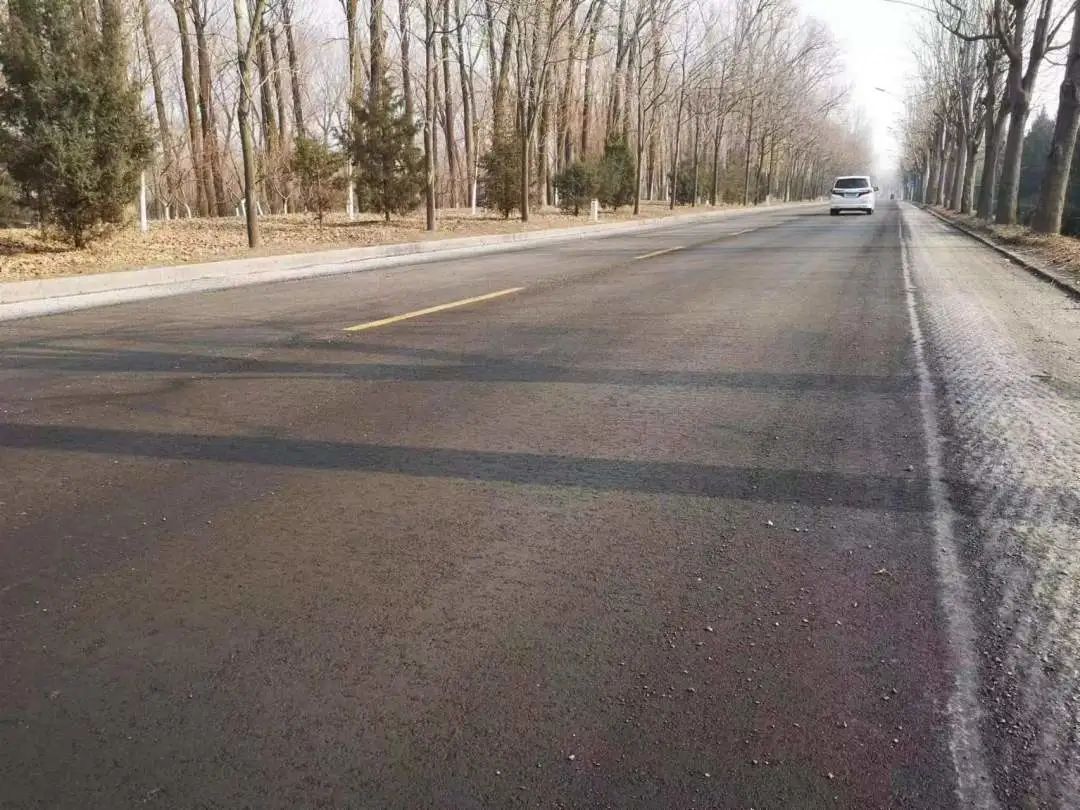

The surface of the structural layer after the foam cold regeneration is finished is smooth and dense.,Has preliminary structural strength,Traffic can be temporarily opened after regeneration。The following picture shows the regeneration section of Wenbei Road, which is temporarily opened to traffic in the early morning after the construction is completed at night.。

03Advantages of cold in-place recycling technology of foamed asphalt

Foam asphalt cold in-place recycling technology can be 100% Use of original pavement materials,Producing a more durable mixture。Compared with the traditional milling and paving process,,Heat energy consumption can be reduced by 60 percent% Above,Reducing CO2 emissions 80% Above,The effect of energy saving and emission reduction is remarkable.。In addition to the characteristics of environmental friendliness,,Its advantages can also be shown as follows::

01

Ffectively reduce reflection crack。 Foam asphalt cold regeneration layer to replace part of semi-rigid material,Reflection cracks can be effectively reduced.。Its strength and fatigue resistance are close to those of coarse grained asphalt concrete.。So,The foamed asphalt mixture can completely replace the lower layer of a high-grade highway or a municipal road。

02

Improve the strength grade of pavement structure。The foamed asphalt cold recycling layer can not only restore the original design capacity of the old road,,It can also improve the carrying capacity of grass-roots units.,Fundamentally improve the strength grade of the road structure。

03

And that construction period is shorten。Compared with other maintenance construction technologies,Short construction period of foamed asphalt cold recycling process、The period of health preservation is short、High degree of mechanized operation,Significantly reduce the time of traffic disruption during construction。

04

And is beneficial to traffic safety and environment-friendly construction.。Cold in-place recycling avoids the transport of materials back and forth,Recycled materials do not need heating,Construction can be carried out at normal temperature.。The impact of construction on traffic and the impact of material dust on the environment around the road are reduced.。

Wenbei Road takes on a new look after the completion of the asphalt overlay of the regeneration layer

04Wei has something to say

In fact,The cold in-place recycling process of foamed asphalt based on synchronous paving is very mature.,The benefits are also very significant.。Currently in Hebei、Tianjin、Inner Mongolia、Xinjiang、Shaanxi、Jiangsu、Anhui、Heilongjiang、Hubei、Qinghai、Xinjiang、Szechwan、Shanxi、Very successful applications in Guangxi and other places。

Under the current low-carbon situation,,Devote major efforts to develop asphalt pavement recycling technology in line with circular economy model,Recycling of waste pavement materials is applied to pavement maintenance and repair.,Turn waste into treasure,It is of great practical significance.。And,Cold regeneration technique mayAvoid environmental pollution caused by waste material,Reduce the need for road construction materials,Reduce the cost of road construction,Create the greatest possible economic and social benefits。

So,Cold in-place recycling technology has a very broad application prospect,It must also be sensitive to environmental factors.,To provide more reference for the maintenance scheme of municipal roads with strict environmental protection requirements.。