Sanyi will accompany you for a warm winter! The most complete winter concrete maintenance tips in history must be collected well!

January 17, 2023With the massive snowfall across the country,,The cold climate environment poses a severe test to the normal use of concrete equipment.。In order to ensure the normal operation of mechanical equipment in bad weather conditions.,Proper maintenance is essential。

Develop good maintenance habits,Can not only prolong that service life of the equipment,、Improve the working efficiency of equipment,It can also provide reliable and powerful guarantee for the normal construction of the project.。

Next, these concrete equipment are maintained in winter.“The secret book”Be sure to collect it well.!

Electric mixer Truck

1、When the Vehicle is used at lower temperatures,Check the water tank before driving、Valve、Whether the pipeline and other components are frozen,If ice is found,It shall be de-iced。

2、To prevent the water in the gas tank from freezing.,The water in the tank shall be removed in time.。

3、Fill the fluid according to the requirements of the climate and environment.。

4、Always check whether the electrolyte of the battery leaks when using the Vehicle in winter、Whether the air vent is blocked。

5、The Vehicle shall be charged in time after operation in winter.,Reasonable allocation of charging piles,Ensure that the queue does not exceed 2 hours.,Due to low ambient temperature in winter,Vehicle automatic heating system needs a process to heat the battery.,Timely arrangement of charging can reduce the charging time in winter.。

6、After the Vehicle is started,Drive slowly and run 3-5 minutes,Drive the Vehicle after reaching the normal temperature of the normal motor and battery。

7、When the air conditioner is not in use,It shall be started once a month,About 10 minutes each time,In order to facilitate the normal operation of the system.。

Pump Truck

One、Precautions for severe cold weather in winter:

1、Equipment engine antifreeze should be replaced in a timely manner.,A wat tank capable of preventing frost crack。Antifreeze is in use2 years or 60,000kmReplace in time(The freezing point of the selected antifreeze should generally10 below the local minimum temperature℃Above)。

2、Add to-Number 10Diesel,Prevent diesel oil from failing to start due to low temperature wax precipitation。

3、The chassis air storage tank shall discharge the residual water timely and effectively.,Replace the Dryer filter element,Prevent water droplets from entering the brake system and causing brake failure due to icing.。If there is water in the gas path,There will be endless trouble。

4、Replace the transfer case/Reducer gear oil,The gear oil will deposit a large amount of water after high temperature.,Not only does deterioration affect lubrication,Prevent the reducer from freezing and cracking。

5、A fully discharged battery can freeze at low temperatures and damage the battery.,To charge an iced battery,It must be thawed(Put it in a warm place),And then charge it.。

6、The Vehicle is idleMore than 1 week,The negative wire of the battery needs to be disconnected;IdleMore than 1 month,The battery needs to be removed and stored upright in0-30℃Dry environment,Must be charged before reloading。

7、Vehicle is parked for a long time,Should1 time/Month,Start the engine,Turn on the A/C switch at idle speed,Allow the engine to idle before turning on the air conditionerAt least 10 minutes,To prevent damage to the air conditioning Compressor。

8、Special glass water shall be filled in the wiper kettle.。

9、When the water pump is used in cold weather,Replace with qualified engine oil,The oil fill is850-900ml,It is normal for the oil filling amount to cause slight oil leakage from the vent hole of the oil plug。

Two、Preparation for work in cold weather in winter:

1、Before driving:EnginePreheat for 10 minutes,Wait for the water temperature,Drive after the oil pressure is normal,Repair immediately in case of any abnormality。

2、Before construction:Remove ice from the sink。Preheat the pumping system,Wait for the oil temperature20℃AboveRe-construction,Protect the pump and hydraulic components。

3、After construction:Timely wash the pipe and clean up the surplus material,The pipe cannot be washed after the concrete in the pipe is frozen。Drain the sink and outrigger tank、Water in the pump,Prevent freezing(When draining water, the water pump and water gun should be turned on, as well as the rubber plug of the sink.,Empty pumping for 3 minutes)。

Three、Maintenance of water tank and water pump in winter

1、Drain the water in the water tank

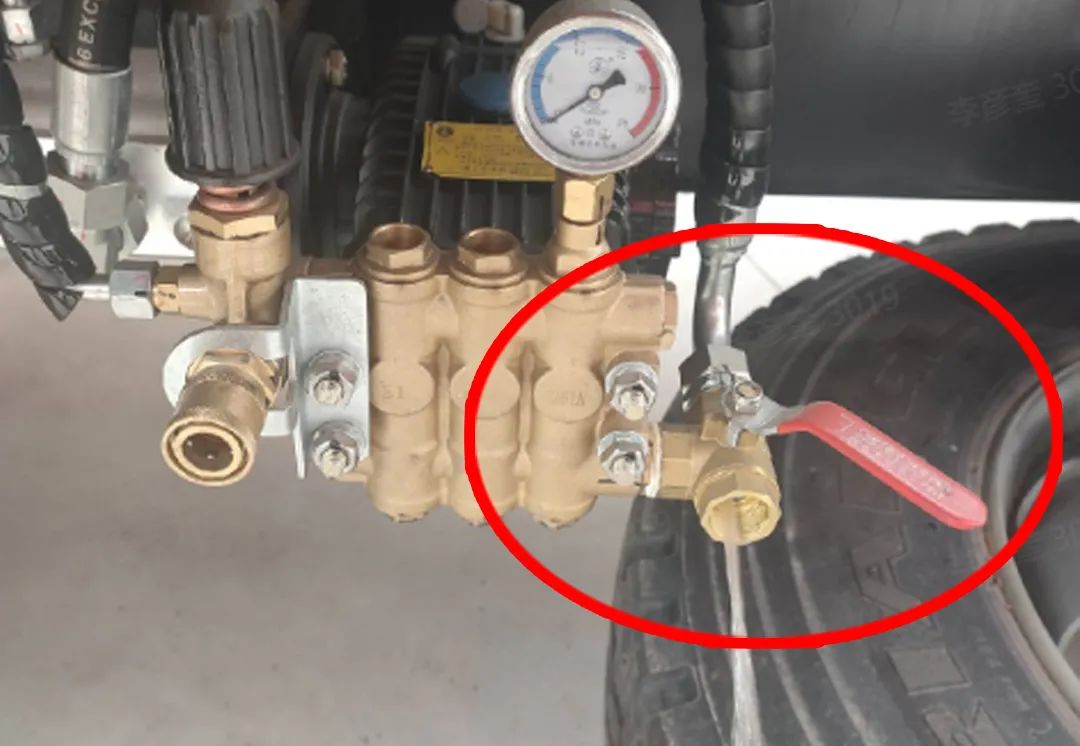

(1)Rotate the water tank drain switch handle to be parallel to the water outlet,Drain the water in the water tank,As shown in fig. 1。

Fig. 1 Water tank drain switch on status

(2)After emptying the accumulated water,Turn off the drain switch,Prevent sundries from entering the water tank,As shown in fig. 2。

Fig. 2 Close state of water tank drain switch

2、 Drain the water inside the water pump and the water pipe

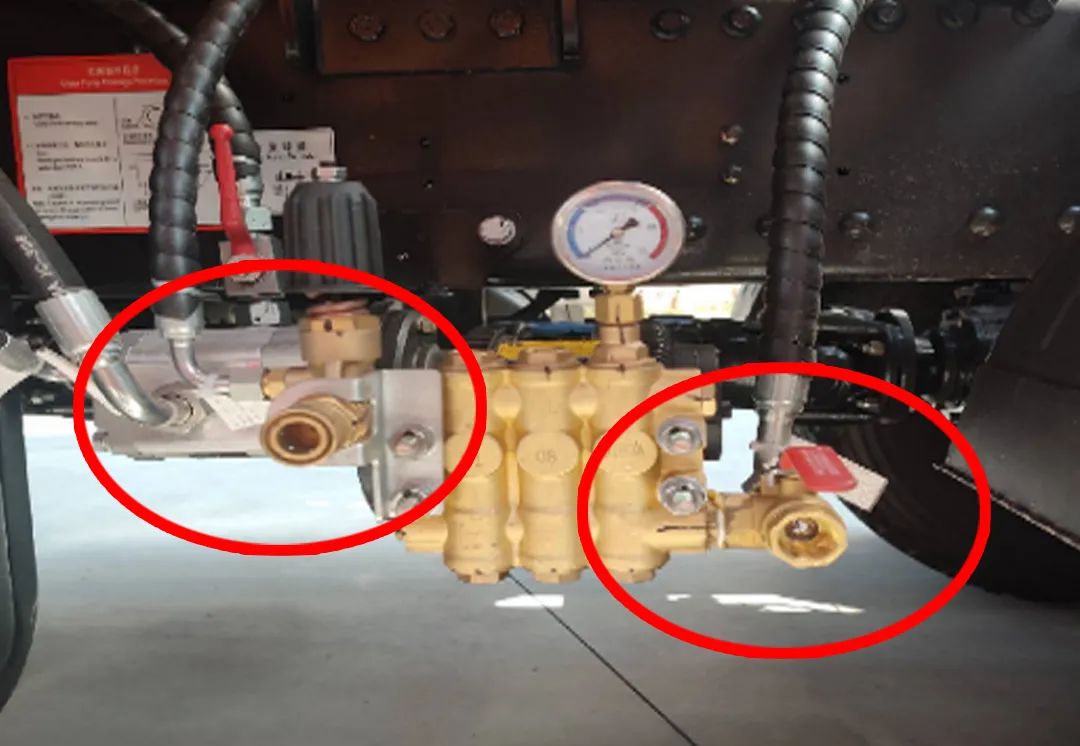

(1)Rotate the switch handle of the three-way ball valve of the water pump to the open state45°Included angleThe location of,Drain the water at the bottom of the water pipe and pump body.,As shown in fig. 3。

Fig. 3 Drain the water in the pump body and water pipe

(2)After emptying the water at the bottom of the pump body and in the water pipes,Turn the switch of the three-way ball valve of the water pump to the open state.,As shown in fig. 4.。Then start the Vehicle and the water pump,Let the pumpRun at no load for 3 minutes,Completely drain the water inside the pump body。

Figure 4 Water pump on status

(3)Drain the water inside the water pump and the water pipe

When the water pump is used in cold weather,Replace with qualified engine oil,The filling amount is850-900ml,It is normal for the oil filling amount to cause slight oil leakage from the vent hole of the oil plug。

Fuel mixer Truck

One、WinterPrecautions in severe cold weather

1、Antifreeze is in use2 years or 60,000kmReplace in time(The freezing point of the selected antifreeze should generally be lower than the local minimum temperature.10℃Above)。

2、Special glass water shall be filled in the wiper kettle.。

3、The chassis air storage tank shall discharge the residual water timely and effectively.,Prevent water droplets from entering the brake system and causing brake failure due to icing.。

Two、WinterPreparation for work in cold weather

1、In order to prevent the diesel oil from freezing,Recommend blending-10#DieselUse,Prevent wax precipitation。

2、Start the engine before Vehicle constructionPreheat for more than 5 minutes,Reduce engine wear。

3、In the process of driving, the Vehicle speed should be reduced to reduce braking when encountering the bridge deck or the back of the sun.,Prevent Vehicle sideslip caused by floating water。

4、Drain the remaining water of the flushing system after finishing the work,A wat tank capable of preventing frost crack、Water pipe affects next use。

Mixing plant

One、WinterPrecautions in severe cold weather

1、When the temperature is below0℃Time,The aggregate conveyor belt is loosened by increasing the counterweight or adjusting the tail to adjust the pull rod degree.,It is advisable that the belt does not slip。

2、After the construction of the mixing station is completed on the same day,The intake pump shall be handled、Drain pump、Water discharge treatment of water metering hopper equipment,Prevent frost cracking of pipeline, pump body and valve。

3、Admixtures at ambient temperatures up to0℃It will crystallize,Will change from a liquid to a semi-fluid state,Preheat before each startup,Prevent the water pump from burning out the mechanical seal due to idling。

4、Air Compressor and air storage tank、Triplet and other places for drainage,Prevent freezing。

5、Turn on the air conditioner in the control room before starting the machine.30 minutes,After the indoor temperature rises,Restart the industrial computer and electrical equipment。

6、After each construction of the mixing plant is completed,The remaining material in the sand and gravel silo shall be emptied,So as not to freeze and affect the next normal use.。

Two、WinterPreparation for work in cold weather

1、Replace the gear oil of each reducer.。

2、Check the scraper plate of the replacement belt。

3、TemperatureBelow 5℃Time,Recommended for mixing machine grease pumpSANY Special No.1 Extreme Pressure Lithium Grease,Prevent the oil supply pipe from being blocked。

Above winter maintenance tips

Everyone must collect it well.

Three One Accompany You for a Warm Winter!