Central Media: Make "Cold" in the Coolest Way

February 07, 2023

In daily life,Coldness is a derogatory term.,It conjures up images of stone-hearted indifference.。But in Danfoss Commercial Compressor China(Tianjin)Factory(Hereinafter referred to as Danfoss Tianjin),Its meaning is quite different.。

Danfoss, known as the world leader in refrigeration,Is the largest industrial group in Denmark。Manufacturer of commercial Compressors by Danfoss——Tianjin Danfoss has been rooted in the Chinese market for more than 20 years.,Yes“Cold”The pursuit has never been interrupted.。

“EnglishCOOLIt has two meanings: cool and cool.。For enoughCOOLCooling capacity,We use cool, industry-leading technology。”Zhang Ruixing, Senior Operation Director of Tianjin Danfoss“Tongue twister”,I said it“Cold”And“Cool”A new solution。

2019,This low-key and pragmatic wholly foreign-owned enterprise,Join the world“Lighthouse factory”Network,It has become the first digital transformation model in Tianjin to win this honor.。

For“Cold”And“Cool”Danfoss Tianjin,Why rely on an ordinary small card?,Get on the high-speed train of the digital economy?Behind the tight screws.,What kind of transformation journey is hidden??

Reporter|Liu Huang、Huang Haibo、Li Kunsheng、Zhang DianbiaoSource of the article|February 4《Xinhua Daily Telegraph》* The full text is 4438 words.,Estimated reading time 12 minutes

The trouble of hundreds of thousands of cards

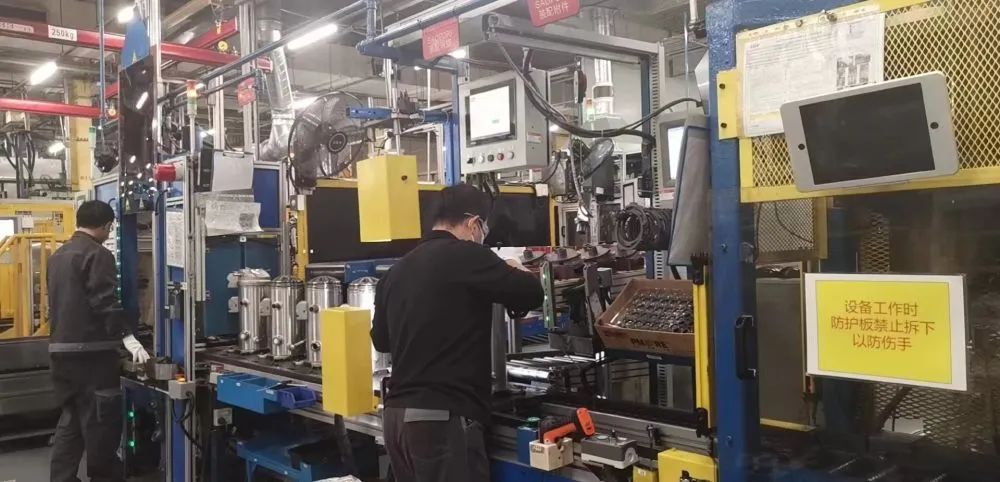

Walk into Danfoss Tianjin Factory,The first impression is simplicity.:In the neat and slightly crowded workshop.,There doesn't seem to be a spare ornament.,It is far from the magnificent multinational company factory in imagination.。

On an automated production line,Site workers in dark grey overalls,Busy as ever,But there are fewer people.,The work is also light.。Intelligent production process is orderly,It's hard to find a hot scene.。

Here,Hundreds of thousands of Compressors queue off the production line every year.,Shipped all over the world,For many supermarkets、Office building、Cold chain logistics provides strong“Freeze”Force。

“With fully digital traceability systems and smart sensors、Visual inspection,Digital tools such as automatic monitoring system,Successfully improved the quality control system,Increased labour productivity by 30% in two years%,Customer complaint rate decreased by 57 percent%。”Expert assessment of the World Economic Forum,It shows that digital transformation ultimately depends on numbers.。

The story behind the automated production line,Zhang Ruixing, who entered the factory in 2003, knows best.。This engineer from Toyota.,Participated in every node of Danfoss Tianjin digital transformation。

In accordance with industry norms,One tracking card per commercial Compressor——Retain all production data。In case of product quality problems,It is convenient for manufacturers to trace and find out the reasons.。As long as the Compressor is not scrapped,This card needs to be kept.。

2012,Danfoss Tianjin produces about 250,000 commercial Compressors annually.,However, a digital traceability system for products has not yet been established.。Tidy、Archive and search these paper cards.,Has become a very troublesome thing.。

“How many rooms does storage take up?,Searching is more like entering a big library.。But the output will increase.,What to do later?”Zhang Ruixing recalls,The factory has tried to scan and input production data.,Because the base number is too large,Worn out a lot of scanners.。

At the same time,This product information remains only on paper.——Data such as equipment operation status, work hour and work order,This can provide a statistical basis for the factory management to make decisions.,Eventually, it becomes data garbage because it can't be shared.。

▲December 7, 2022,Workers are working on the production line of Danfoss in Tianjin.。

Since 2012,Danfoss Tianjin All Digital Traceability System Officially Launched。

The partner of this digital transformation project——Tianjin Aidi Automation Technology Co., Ltd.(Hereinafter referred to as Aidi Technology),It is also the equipment integrator of Danfoss Tianjin.,Yi Guocheng, the person in charge, recalled.,At that time, the last stop of each workshop,All with a thick stack of tracking cards.。

“After the transformation,Electronic Kanban replaces paper tracking card,The scene felt refreshing all of a sudden.。”He added。

From building a digital traceability system,To apply various digital tools.,Then to the introduction of robots and vision systems.,The whole factory has become smarter.、Efficient。

In order to solve the problem of misloading、Assembly problems such as missing assembly,Each workstation is implemented through an interlocking system“Interlock”Pattern:An error occurred in the previous session,You can't get to the next process.,This ensures that the customer complaint rate remains below 50 parts per million。

In the past three years,The world of intelligent manufacturing“Lighthouse factory”Keep on shining:Continuous double-digit increase in production efficiency,The rate of customer complaints has also declined by an average of double digits annually.……

You can make a book just by talking about screwing.

Luo Huiping, the assembly process manager, spoke quickly.,Very capable。Talk about the road to digitization,She said with a smile.:“Just talking about screwing.,You can publish a book.!”

Assemble a Compressor,It is usually necessary to tighten more than ten screws.。In the past, workers tightened screws.,Use a manual clicker wrench or a pneumatic wrench。Because these torque spanners have no data acquisition function.,Inevitably, there is a phenomenon of missing or not in place.,Leave hidden quality hazards。

2012,The factory has introduced a well-known brand of electric wrench.,Not only can the torque be calibrated,You can also collect all the data of the upload job process.。

New tools bring process changes,The actual efficiency is limited.。Proposed by the factory management,Is there a wrench that can tighten two screws at the same time??

This non-standard tool requirement,The equipment supplier and the engineers in the factory are in trouble.。Although there are solutions for simultaneous fastening of multiple screws in other industries,However, due to the differences in production process and product accuracy,,Everyone thought it was impossible at first.,But we didn't give up.,Toughen one's scalp to study and tackle key problems,As a result, it was actually done.。

2016,The workers used a double-ended fastening wrench mechanism customized for the Compressor production process.,The operation efficiency is improved by about 50%,Labor intensity has been reduced synchronously.。

▲December 9, 2022,Danfoss Tianjin managers are discussing the equipment improvement plan.。

Not long,The management has made new demands.,“Since two screws can be screwed at the same time,,Why don't you try four screws together??”

Luo Huiping led the team to design repeatedly.、Test,Until 2018,The workstation uses a four-head fastening wrench.。The production line is also equipped with photoelectric error proofing and sequence error proofing.,Ensure correct operation by workers。

Once you taste the sweetness of efficiency.,The impulse to upgrade becomes difficult to suppress.。With the launch of a new production line,,They decided to adopt an automatic nail feeding mechanism.、Industrial vision system and robot automatic fastening system,Recognition of fastening hole position by automatic photography,The full-automatic screw fasten of that Compressor is realized。

That's all,A stubborn screw has finally completed the digital transformation of automation.,The hands of the workers were completely liberated.,Realized“Machine replacement”A historic transformation。

Over the past 10 years,The factory has always had about 600 employees.,The annual output has climbed from more than 200000 units to nearly 600000 units.,The average time to assemble a single product has also been reduced from 160 seconds to 60 seconds.。

Zhou Li, who entered the factory in 2003,He was one of the first 20 workers in the Compressor production line.。From an ordinary employee to a production foreman,He has always been in a front-line production position.,The experience of digital transformation is more direct。

“The two workstations are only three or four meters apart.,It used to take more than 20,000 steps a day to go back and forth.,He had to lift more than 20 kilograms of metal repeatedly for more than 400 times.。”Zhou Li's words reveal the hard work of that year.。

It is worth mentioning that,The factory has set up a wall of suggestions for improving the production process.,Many golden ideas are put forward by front-line workers.。So far,The monthly process improvement conference has lasted for more than 200 times.,Develop a factory culture of continuous improvement of production processes。

When the automatic nail feeding mechanism is just started in the factory,If the diameter of the screw cap exceeds the standard, it will jam.,Must be removed to resume operation。Zhou Li's team according to the suggestion of the staff,A special screw is designed to intercept the exceeding standard.“Filter door”,Cleverly solved the problem.。

Zhang Ruixing said,I have never been absent from a process improvement conference.。He said rather proudly.,Active participation of employees in the production process transformation,It's global“Lighthouse factory”An important guarantee for sustainable development。

Welding robot becomes a porter

Danfoss Tianjin Builds the World“Lighthouse factory”,Actually“Walk through some crooked roads,I have also suffered some losses.”。

2018,Wrench supplier launches smart wrench,Compared to the pulse-type wrench before the upgrade,Torque of new products is more precise and controllable。

Workers at the scene found after using it.,Because the surface of the screw is often attached to some welding slag.,Resulting in an increase in friction,Smart wrenches are often misjudged.。

“It mistakenly thought it was clamped.,Actually, it's fake.,May cause Compressor leakage。”Zhang Ruixing said。

Fortunately, the factory has a group of engineers who are good at learning.,The angle control method is designed to replace the torque control method.——Suppose it takes 50 N to tighten a screw.,First set the smart wrench to 40N.,Then add an angle value.,Make sure to clamp,Eliminate potential quality hazards。

▲Automatic fastening scene of Danfoss Tianjin production line(Photo taken on December 7, 2022)

Coincidentally。To match a pair for the robot.“Wise eye”,And realize that disorderly grabbing of the workpiece accord to needs.,It also made them struggle for a while.。

2017,Equipment introduced into the plant 3DThe robot of the camera。In the lab,3DThe camera works smoothly with the robot.,And that grab accuracy is high。The engineers happily took the robot back to the factory.,Only to find them“Not acclimatized”Here we go。

Engineering Customer Quality Manager Frontier Memories:“In the lab, they catch one by one.,When we get to the workshop, we can't catch it accurately.。Experts at home and abroad have consulted once.,Still not。”

During that time,Yi Guocheng has been running back and forth between the laboratory and the factory floor.。“This line has more than 50 models of mixed production.,The parts all look the same.,Camera recognition is very difficult.,Finally, the robot can only be replaced by other brands of industrial cameras.。”He explained。

At present,The factory has introduced about 50 robots in total.,For welding、Spraying、Assembly and other labour-intensive processes。

“Many processes are replaced by robots.,For example, the interior line originally needed 9 operators per shift.,Now there are five operators and six robots.。”Zhou Li said。

▲January 30,Danfoss workers assemble products in Tianjin。

It's interesting to say,The first batch of welding robots entering the factory,A year later, the engineers“Tame”,Change one's profession to specialize in heavy work“A porter”。

“Welding robots are relatively inexpensive.,Plus, we already know these machines.,In order to save costs, they temporarily let them work as porters.。”Frontier added。

The welding robot can lift up to 50 kilograms.,At first, he was competent.,As more and more large items need to be handled,,And then I couldn't move it.,The factory just bought a professional handling robot.。

Most of the intelligent upgrade and transformation of Danfoss Tianjin,It is completed by its equipment engineers in cooperation with suppliers.,Full of“Tuyang”Combined colors,This has also trained a group of excellent engineers.。They may be skilled in equipment transformation.,Or skilled in system development,Or understand both technology and management.,Formed an enterprise-level intelligent manufacturing talent echelon。

“We pursue lean manufacturing,It is to simplify complex processes.,Simple process standardization。The technology and process chosen may not be the most advanced,But it must be the most practical.。”Zhang Ruixing concluded。

Lately,He also recommended a book to his colleagues.《Subtraction》,“This book reminds us not to go to extremes.,Simplify the complexity to achieve digital transformation。”

The lighthouse has to let others see your light.

Not so long ago,A production manager in charge of digitalization in the factory,He was employed by an enterprise in the south with high salary.,What the other side values is the effectiveness of Danfoss in digital transformation.。

Zhang Ruixing is happy to see this flow of talents.,“As‘Lighthouse factory’,You should tell others how to go.,Let others see your light.。”

This year is Luo Huiping's 13th year in the factory.,“In the first few years.,We are more led by suppliers.,Now slowly begin to drag them along.。”

“All these years,They do have more and more demands.,More and more meticulous。A lot of the requirements are new to us.,It also forces us to grow up.。”Yi Guocheng said,Many of my clients will visit and study in Danfoss by name.。

▲Exterior view of Wuqing Park in Denver(Photo taken on May 13, 2022)。Xinhua News Agency reporter Xu Jian photo

Danfoss commercial Compressor is in the process of assembly,It is necessary to adjust the coaxiality of the upper and lower bearings inside.,The allowable error value must be controlled within 0.Within 04 mm,This is a challenge that Eddie Technology has never faced before.。

“Danfoss's plant in Denmark has this application case.,We have carefully studied and thoroughly understood the principles.,Add your own innovation.,Help Tianjin factory to realize the landing of this application.。”Yi Guocheng said。

The engineer who came out of Motorola in Tianjin thinks that,In Tianjin and even the whole country.,Advances in the automation industry,It is inseparable from the landing of foreign advanced manufacturing enterprises in China.。

“After Motorola came to Tianjin,,It quickly attracted several Singaporean enterprises to engage in non-standard services.,Then it slowly led to the development of Tianjin's non-standard automation industry.。”Yi Guocheng said。

2021,Danfoss Headquarters Closes US Compressor Plant,All products are moved to Tianjin factory for production.,Including orders for more than 200 models of 100,000 commercial Compressors。2022,The enterprise plans to invest 300 million yuan.,Introduce and build more than 10 sophisticated new production lines,It is expected to bring 800 million yuan of new output value to the factory every year.。

Same year,The total investment is nearly 1.400 million yuan“Global Refrigeration R & D and Test Center”Sign a contract with Tianjin,It is the sixth time since Danfoss settled in Tianjin.,It is also the largest capital increase.,It shows the confidence of this foreign-funded enterprise in the Chinese market and Chinese manufacturing.。

67 years ago,The first refrigerator made in our country“Snowflakes”Born in Beijing。The most critical component——Refrigeration Compressor,From as far away as Danvers in northern Europe。

27 years ago,Danfoss Commercial Compressor Settled in Wuqing, Tianjin,Become the first factory to take root in the Chinese market。Nowadays,China has become the Nordic company's second largest regional market and largest procurement market in the world.。

“Within our group,The digitalization level of Danfoss Tianjin factory is in the first level.,This has a lot to do with the Chinese market and China's overall economic and technological development.。”Zhang Ruixing did not hide his pride in the factory where he worked.。