Maleny Popular Science Paste? All-in-One Machine? Split machine? What if I can't tell? Take a look at this popular science guide.

February 10, 2023Due to the geographical differences of economic development in different parts of China,,Application of Regeneration Equipment,Basically, it starts with coastal areas such as Jiangsu, Zhejiang and Shanghai.,Gradually extend inland,Many customers in the inland market who have not been exposed to recycling equipment before,There may be no concept of plant mixing and recycling equipment.。It does not discriminate between the two devices.,It is easy to change the concept stealthily,Confuse products with technical generation difference。So,This is the concept of the all-in-one machine for mixing and recycling in the general plant of liberal arts.,So that the majority of users to avoid being taken in。

Malani plant-mixed and recycled integrated Asphalt Mixing Plant(English abbreviationFRT),It was Malini who introduced the advanced recycling technology of old asphalt materials from Europe.,Aiming at the special requirements of the plant-mixed hot recycling of the current asphalt mixing fixed station,Specially developed Asphalt Mixing Plant,Lay particular stress on the addition of plant-mix hot recycling of old asphalt。The process of such equipment and the traditional asphalt master station+Same combination of regenerating equipment,But the structure has changed a lot.,Therefore, it is widely called the plant mixing and Recycling Machine in the market.。

Its main features are,To ensure the production capacity of raw materials

At the same time,Is more convenient for the addition and production of the old asphalt material

The old asphalt is added vertically into the mixing pot.

Reatly reduce the sticking problem of the old asphalt material

Effectively reduce the wear and tear of old asphalt on equipment

Reatly reducing the overall height of the plant-mixing regeneration equipment

Malani launched its first set of recycling all-in-one machine in China in 2016.(FRT360),Since then, the concept of Recycling Machine has been gradually accepted by the market.。Due to the high market popularity of the product,Therefore, the product and its concept have been imitated by many manufacturers.。As of January 2023,Malani has sold more than 60 sets of recycling equipment in China.,It has become one of the most mature manufacturers of asphalt plant-mixing and Recycling Machines in China.。And in the original main productFRTOn the basis of 360,Has developed a variety of Recycling Machine models suitable for different capacity needs.,Form a completeFRTProduct line。

Popular Science Guide

Technical Advantage

FRTThe biggest feature of the series is to translate the position of the mixing pot to the bottom of the regeneration parallel drum.。

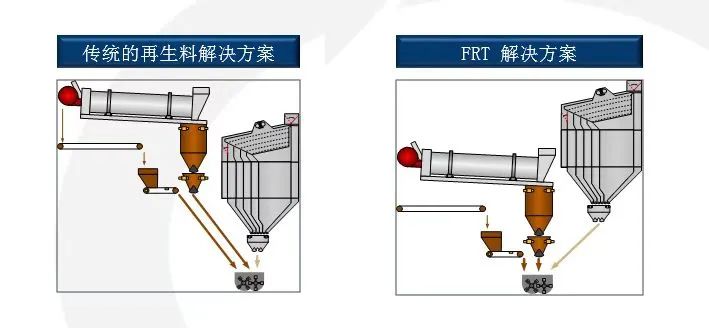

The design principle is shown in the figure below.:

FRTThe arrangement form abandons the traditional structure of feeding the boiler through a chute or a belt.,Tructurally avoiding heatedRAPMaterial adhesion problem,Meanwhile, the overall height of the Asphalt Mixing Plant is reduced。

The frame of Asphalt Mixing Plant is designed as a whole.,There is no staggered layer at the overlapping position of each module.,One step in place,The sticky material of the heating recycled material is avoided from the structure.、Blockage and other problems,Measures such as spraying of anti-sticking agent in the chute to prevent sticking and blockage have also been banned.。Improves the metering precision and the adding proportion of the recycled material,Better control of finished material quality。The overall equipment is more environmentally friendly、Energy saving。

In order to better distinguish between the two structures,After 2017, the traditional original is widely used in the market.+Regeneration equipment is called split machine.,And putFRTThe structure is called an all-in-one machine.。Since then, the name of the plant mixing and Recycling Machine has become popular.。

There is no difference between the production functions of the two kinds of Asphalt Mixing Plants with different structural characteristics.。However, the split machine is produced every time.,The regeneration chutes need to be checked and cleaned,Otherwise, it is easy to cause blockage of the chute,Cause the equipment to be unable to be used normally。But also due to the inherent characteristics of recycled materials,,It is very easy to stick after heating.,After cooling, it is tough enough and not suitable for removal.,Therefore, it must be operated while hot at the end of each production.,Due to the narrow location、The chute is long,Therefore, the operators are laborious.。

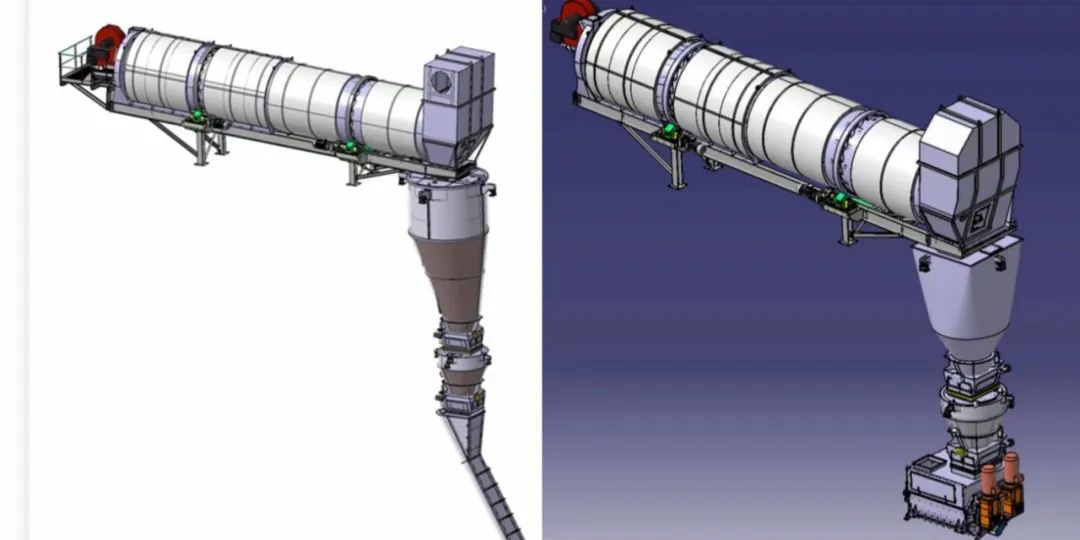

Design drawing of regeneration part of split machine design Design drawing of the regeneration part of the all-in-one machine

Sub-design

Photos of the reproduction part of the split machine Some photos of all-in-one machine regeneration

Obvious,The design of the all-in-one machine is more suitable for the production of plant-mixed hot recycling.。The split machine was designed in the 1990s.,All-in-one machine is the molding design after 2014.,There is a generation difference of nearly 20 years,The all-in-one machine is more advanced than the split machine in design.,It can be called an epoch-making product design in the field of asphalt mixing equipment.。

Say a thousand words and ten thousand words,The procurement of such large equipment,It's a technical job.,Not only professional knowledge is required,,A clear understanding of technical concepts is also required.,More importantly, we should have extraordinary vision and judgment.。Blind purchasing,Will only let oneself into a misunderstanding.,Although it is not enough to make a mistake that will lead to eternal regret,But in the end, regret is also common.。Maleny with 123 years of development history,With strong technical accumulation and tireless spirit of ingenuity,Constantly bring forth new ideas,Lead the industry development。Facing the increasingly diversified needs of customers in the Chinese market,Maleny seeks innovation and change.,Never go through the motions,Put the latest technology、Bring the best products to users,Actively provide all-round services,Meet customer needs,Exceed customer expectations,“True gold fears no fire.”,Maleny welcomes you to examine and compare the choices.。