Shaorui Overseas Travel | 30 days! Shaorui Heavy Industry Modular Installation in the Philippines to Build a High-efficiency and Low-consumption Production Line!

March 31, 2023Build the whole production line at a time.,I believe many people are beginning to frown.:“The whole line is stable and has nothing to say.,But the construction period is long.,The input consumption is large。 That ,Is there a best of both worlds solution??”Of course there is,Today, we will bring you to Cebu, the second largest city in the Philippines.,Take a look at how we efficiently build our aggregate production line.。

Project files

Construction time:2022/11/24

Project location:Philippines·Cebu

Project process:SZ1360 feeder+SJ1200 jaw Crusher+SG260SSingle-cylinder hydraulic cone Crusher+SCH4000 multi-cylinder hydraulic cone Crusher+2SS2570 Finished product screening machine&The finished product is washed and sieved

Project capacity:300 tons/Hour

Project feed: Basalt

Discharging the finished product:0-5mm, 5-10mm,10-20mm,20-40mm

Other components:Head breaking hammer; Modular standard steel foundation and conveyor; Automatic control system of the whole line; Sewage treatment system

Shaorui customization:Whole line process、Process and layout design;Installation and debugging;On-site Operations Customized Training

01

Adjust measures to local conditions

According to the actual situation of the site and the production requirements of customers.,The layout design of the production line is fully adapted to local conditions.,AdoptStepped site layout,Make rational use of space,At the same time, it also reduces the investment cost of customers to build factories.。

02

Flexible design

The project adopts a 3-stage crushing design.,Through the design of flexible and adjustable material receiving and distributing hopper,Flexible switching between open-circuit and closed-circuit production processes,Give full play SCHAdvantages of 4000 Multi-cylinder Hydraulic Cone Crusher,The grain shape of the finished product is obviously superior to that of the local similar production line.。

At the same time, the production line is equipped with finished product washing screen.,The grade quality of that finished product and the environmental protection advantage of the production line are greatly improved,Establish the competitive advantage of customers in the local market,Maximize return on project investment,Become a benchmark project for local aggregate production。

03

Modular installation

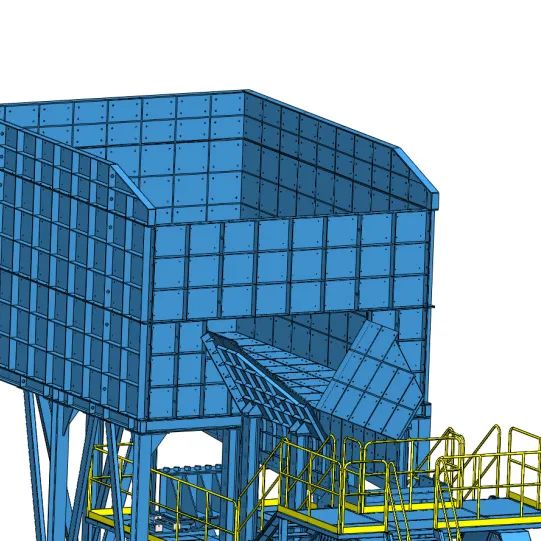

Production lineModular standard steel structure foundation and conveyor products independently developed by Shaorui Heavy Industry Co., Ltd.,Upon arrival“Build blocks”Installation,There is no need for any processing modification on site.,Build and use immediately,And that installation difficulty is greatly reduce.,And that installation efficiency is improve,It only takes 30 days to reach the production line linkage test.。

04

Automation

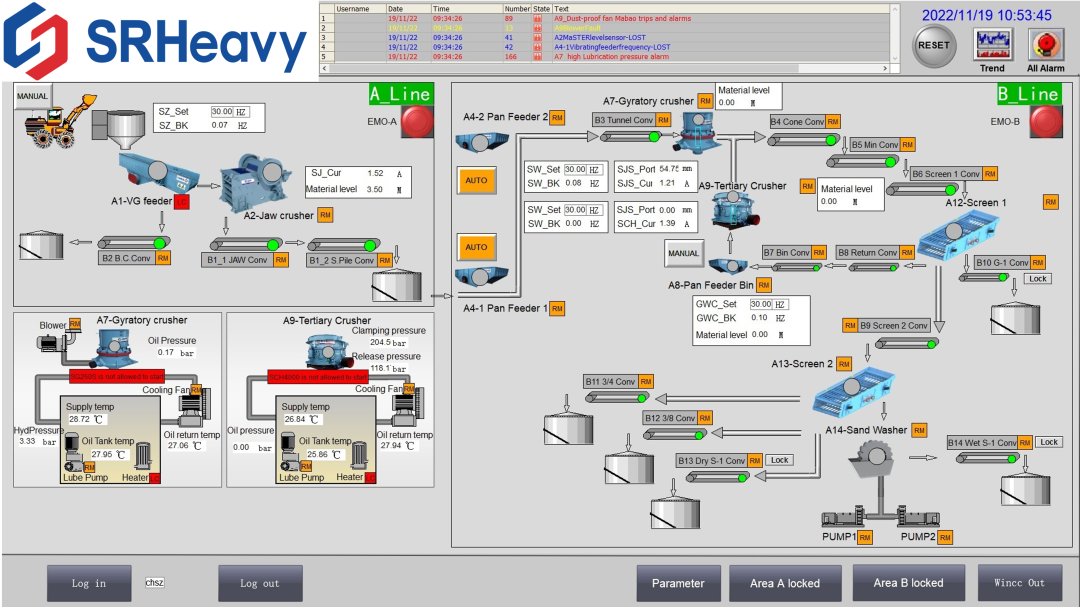

The production line is controlled by industrial computer automation and manual control system.,Complete process parameter detection function,Automatic adjustment is possible、Optimize host device parameter,Achieve real-time capacity automation adjustment,At the same time, it is equipped with the best safety instruments and interlocking function design in the industry.,Provide maximum security on the premise of maximizing production capacity。

05

Reduce operating costs

The material transfer part of the production line is designed with special structure.,AndAdd high-performance wear-resistant lining plate,Reduce customer operating costs。

Configuration of key positions of production lineCCTVMonitoring and remote detection system,Realize background remote network port monitoring,Realization“Zero distance”Keep abreast of the operation of the production line and the main parameters of each equipment.,Remote monitoring of electrical control equipment,Accurately eliminate abnormal electrical parameters,And that program logic of the correspond automated program system is remotely Chan and edited according to the requirements of the client,Optimize production operations in real time。

It is reported that,The project is currently running smoothly.,We will also continue to track the operation of the project.,Strive to achieve“Defining the Global Aggregate Mid-Market,Drive customer success”。