The world's first variable-diameter inclined shaft roadheader was launched in Tiejian Heavy Industry, realizing 50 ° super-large inclination continuous climbing, 6.53 meters and 8 meters variable diameter excavation.

April 21, 2023April 20,One can achieve 50°Super steep climbing、6.53-meter and 8-meter tunnel Boring Machines with variable diameters were launched in Changsha Primary Industry Park of Railway Construction Heavy Industry.,This is the world's first variable diameter inclined shaft rock tunnel Boring Machine.,This marks a new breakthrough in China's underground construction site equipment.,It fills the gap in the field of full-section mechanized construction equipment for two-stage inclined shaft with super-large slope in China.,It further enriches the global Roadheader product spectrum.。

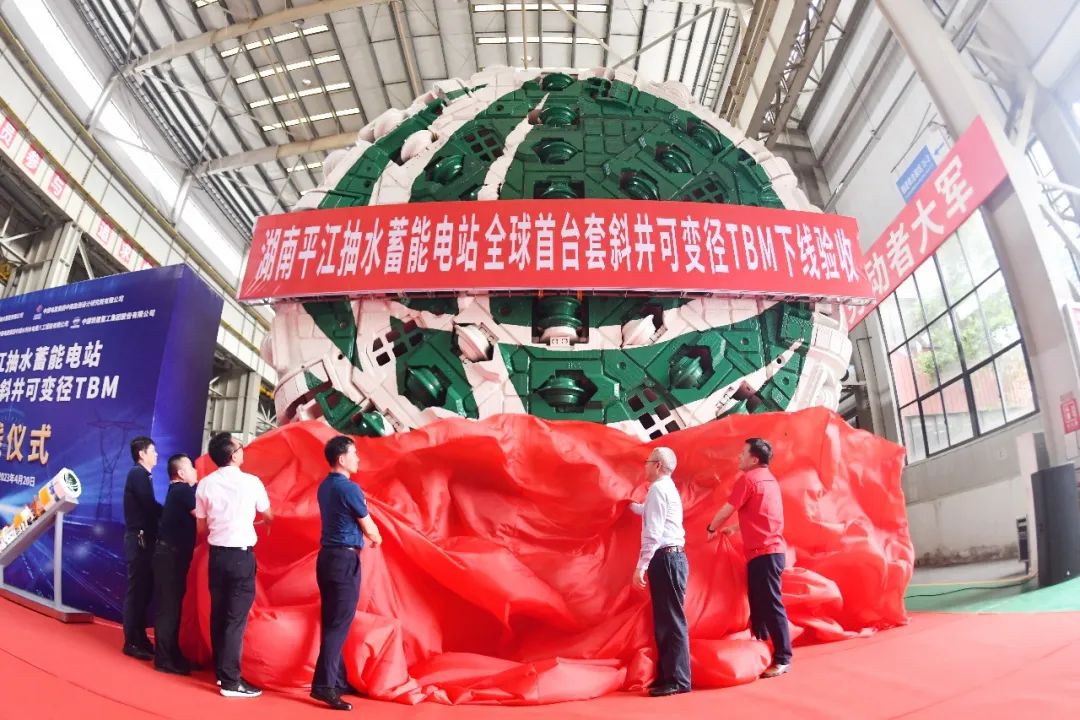

Equipment offline site

Party Secretary of Hunan Pingjiang Pumped Storage Co., Ltd.、 Chairman Tang Jianguo delivered a speech and announced that the equipment was offline.

Wen Wenjun, Deputy Chief Engineer of Zhongnan Survey and Design Institute Co., Ltd. of China Power Construction Group, delivered a speech.

Speech by Ren Langming, Deputy General Manager of Sinohydro Bureau 8 Co., Ltd.

Deputy Secretary of the Party Committee of Railway Construction Heavy Industry、Director、General Manager Zhao Hui delivered a speech

This device is named“Tianyue”,The total length is 87 meters、Total weight about 900 tons,By China Railway Construction Heavy Industries、State Grid Xinyuan Hunan Pingjiang Pumped Storage Company、Jointly built by Sinohydro Bureau 8,Will participate in key energy projects in Hunan Province——Construction of Inclined Diversion Shaft of State Grid Xinyuan Hunan Pingjiang Pumped Storage Power Station。Under construction,Flexible transformation of equipment,Achieve excavation diameter 6.Free switching between 53m and 8m,It also has the ability of continuous operation of horizontal adit and 50 degree super-large inclined shaft.。

Hunan Pingjiang Pumped Storage Power Station is located in Fushoushan Town, Pingjiang County, Yueyang City.,The total investment of the project is 8.8 billion yuan.,Total installed capacity is 1.4 million kilowatts,Design annual power generation 10.0.9 billion kilowatt hours,It is the largest pumped storage power station under construction in Hunan Province.。The diversion inclined shaft tunnel is the key part of the hydropower station construction.,The height difference of the inclined shaft tunnel reaches 648 meters.,Compared with the tallest building in Hunan at 452 meters“National Financial Center”And 196 meters higher.,Such as the use of traditional construction methods.,Unable to effectively cope with the complex climbing environment,Extremely high security risk。

“Tianyue”The construction method of climbing from bottom to top with a large slope of 50 degrees is adopted.,The world's first technology,The full-section excavation of the two-stage diversion inclined shaft can be realized.、Primary support one-step forming,It solves the problem of long construction period caused by using pilot shaft and drilling and blasting method.、Low security、High labor intensity and the like.,Finish more efficiently、Safer、Smarter inclined shaft tunnel construction。

The R & D team of China Railway Construction Heavy Industries has made bold innovations in the design.,Initiatively put forward the configuration of multiple anti-slip systems and emergency security systems.,Comprehensive guarantee of operation safety under various working conditions。At the same time,The R & D team has overcome the problem of large-scale diameter change of cutter head and shield body.,So that that diameter range of the tunnel machine is expanded to 1.5 meters;For the first time in the world, the problem of ultra-small vertical curve turning with a radius of 50 meters has been solved.,So that that tunnel machine can adapt to the horizontal tunnel、Inclined shaft、Continuous drivage at turning section,It greatly improves the engineering adaptability of equipment construction.。

In order to speed up the construction of pumped storage power station,Help to achieve“Double Carbon”Aim,The project is under construction.,Vigorously push forward“Mechanization and personnel reduction、Automated replacement、Intelligent unmanned”New concept of green intelligent construction,Actively build a demonstration highland for the application of Roadheader in pumped storage power station。In the construction of pumping inclined shaft,The average monthly footage of the traditional drilling and blasting method is about 40 meters.,After the Roadheader is used for construction,Monthly progress can be increased to 200 meters,It greatly reduces the safety risk of construction workers.,Realize zero application of initiating explosive device,“Tianyue”Mechanization of Pumped Storage Power Station Engineering in China、Greening、Digital construction has injected new impetus.。

It is understood that,“Tianyue”It is the successor of Pingjiang Pumped Storage Power Station in Hunan Province.“Pingjiang”Rear of small-section Roadheader,Another construction tool used in engineering construction,Powerful acceleration of China“Zhi”The pace of boosting the construction of pumped storage power stations。