Weifen Welfare | Wirtgen Large Milling Machine Conveying Belt Promotion Activity is in full swing

May 08, 2023Passionate May,Work is in full swing!May is the peak season for construction.,It is also the busiest period for road construction and maintenance industry.,All kinds of mechanical equipment,For example, large Milling Machines play a vital role.,Provide efficient and sustainable support for engineering projects。Use and maintenance of these mechanical equipment,It also needs to be more cautious and meticulous.。

The influence of the conveying belt on the milling output is self-evident,So how to self-check the wear of the Milling Machine belt?,It is very necessary to deal with the degree of wear in advance.。Next, Xiaowei will take you to learn how to self-check the conveyor belt and how to deal with the wear.。

If you already know how to perform a self-check for the wear condition of the feed belt,And that conventional wear of the belt is severe or abnormal wear has occur.,It is necessary to consider replacing the conveying belt,Coinciding with the special spring promotion of the original conveying belt of Wirtgen large Milling Machine,Don't miss it。(Activity deadline:May 31, 2023)

Conventional wear of the upper surface layer of the conveying belt

During normal operation of the Milling Machine,Friction occurs when the milled material comes into contact with the upper layer of the conveyor belt,As well as the contact between the roller and other parts of the conveying system and the lower layer of the belt will also produce friction.,All these will cause wear and tear on the conveying belt.。The degree of wear gradually accumulates with the increase of working hours and the output of Milling Machine.,So how to judge the wear and tear??The most intuitive way is to visually check the different positions of the belt.。

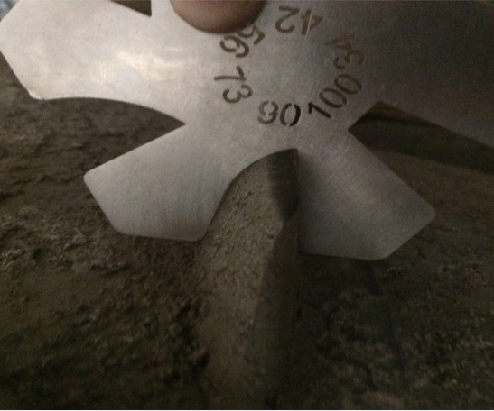

It can be seen that the conveying belt has appeared, and the top of the belt edge has been worn flat.。The tool in the picture is a special tool for Wittgen to check the belt wear.,The condition of the worn belt edge can be measured

If compared with the picture above,It can be seen very intuitively that the entire size of the belt rib is worn down.

If your Milling Machine has been used for a long working hour(Large Milling Machine:About 1000 hours),Wear can be clearly observed,It is recommended that you directly contact the service staff of the local agent of Wirtgen in China.,Test your belt for wear,Give specific advice on when to replace the conveyor belt。(Click on the link to see the promotion details of 2023 Wirtgen China Large Milling Machine Conveyor Belt)

Severe wear:It has been the case that the rubber layer is abraded to expose the lower fiber fabric layer

In addition to the observation of belt edge wear,The upper layer between the edges of the belt can also be observed。The above rubber layer is partially and completely worn.,It is recommended to replace the conveying belt as soon as possible.,Otherwise, there is a risk of belt breakage.。

Normal wear of the lower layer of the conveying belt

Observe whether the lower fiber fabric layer is exposed after the rubber layer is worn.

After the rubber layer is worn,The lower fiber fabric layer is exposed in a large area

In case of severe wear as described above,Please replace the conveying belt as soon as possible.。

Abnormal wear due to wrong belt tension settings

Rib cracking of the belt, usually due to excessive belt tension

There are longitudinal cracks and slight transverse cracks on the edge.,It is also usually caused by excessive belt tension.

If the function is not seriously affected,Crack repair kits can be used to quickly repair cracks on the jobsite,As an emergency measure。But if there is a risk of permanent damage to the belt,The matching belt should be replaced as soon as possible to avoid the risk of shutdown.。

Due to excessive belt tension,Only 250 working hours,There is an abnormal wear condition in which the belt is heated and decomposed.

In the case of the above,The belt has a large area of rubber falling off,It is necessary to replace the conveying belt in time.。

Abnormal wear and tear caused by unexpected conditions on the construction site

Hole caused by stone breakdown

The conveying belt cannot be used normally.,The belt needs to be replaced in time.。

The above is the self-inspection method given by Xiaowei in case of abnormal wear of the conveying belt.,You can perform a self-test against your device,If abnormal wear is found,It is recommended that you replace the belt in time.,So as not to delay the construction period。