[Case Sharing] Application of Topcon 3D Paving System in Anyang Section of Taihang Expressway

June 09, 2023Project overview

The project along the Anyang section of the Taihang Expressway is in Henan Province.“13445 engineering”First batch of diced items,It is also Henan Expressway Planning Network 2021.-It is an important part of Taihang Mountain Expressway in 2035.。The total length of the route is 83.8 kilometers,New paragraph 58 therein.93 kilometers,Concurrent with Nanlin Expressway 24.87 kilometers,The whole line is located in Linzhou City.。Project adoptionBOTPattern,Led by Henan Transportation Development Group Co., Ltd. and China Communications Second Highway Engineering Bureau Co., Ltd.、The consortium composed of Henan Highway Engineering Bureau Group Co., Ltd.。

The construction of this project is divided intoYASG-1 Bid segment andYASG-Two bid sections of Bid Section 2 shall be implemented,Which was undertaken by the Fourth Company of CCCC Second Highway Engineering Co., Ltd.YASG-Bid section 2 is the first、Used in the second work areaTopcon 3DPaving systemIt is used for the paving operation of the water stabilized layer.。Topcon 3DPaving system is designed for road construction in advance.DDigitize, that isBIMModelling,Through the Global Navigation Satellite System and laser technology.,Plane and elevation accuracy of high-precision three-dimensional control paving operation,The automatic control of paving operation is realized.。The adoption willBIMDesigned for direct use in road construction operations,Equivalent to directly on the road surface3D“ Print ”,This project uses the world's leading 3.DDigital and intelligent construction technology,Realized“Automation and efficiency”、“Digitalization and quality improvement”And“Intelligent personnel reduction”。

Introduce 3DPaving technology

The Fourth Company of CCCC Second Highway Engineering Co., Ltd. is the main body of construction along Anyang Section of Taihang Expressway.,Topcon 3 was first used in this projectD mmGPSPaving control system,It ensures the scientific implementation of project construction.、The conduct of norms,And meet the high standard requirements of the Owner and the Chief Supervision Office for ensuring the project quality and schedule.,Through digital management,Full process control,Comprehensively improve the construction technology,Complete the phased work of water-stabilized paving on schedule with high quality。

Beginning at the end of September 2022,In the start-up stage of the water stable layer test section of the project,The Fourth Company of CCCC Second Highway Engineering Co., Ltd. took the lead in adopting Topcon 3 in the first work areaD mmGPSThe paving control system is equipped with Tianshun Great Wall Paver for precise paving control of water-stabilized layer.,After successful completion of the test section and completion of curing,That is, the formal adoption of 3DThe paving control system carries out the continuous paving operation of the water stabilized layer.。

The following early October,Topcon 3 is also used in work area IIDThe paving control system carries out the paving construction of the test section of the water stable layer.,So far, Topcon 3 has been fully adopted in the two work areas.DThe paving control system carries out the high-precision paving construction operation of the water stable layer。

Topcon 3D mmGPSPaving system is based on roadBIMModeling techniques,Combination of satellite positioning and laser height control technology,Achieve automation、Simplify、Mechanical automatic construction control system for high precision construction。Real-time differential positioning by satellite and laser height control technology,No need to measure and set out in advance、Smash pile, hang line and erect guide beam,Substantially reduce the input of labor force,Reduce the potential safety hazard of man-machine cross operation,At that same time, the influence of human factor on the smoothness of the road is avoided,、Impact of key data such as elevation,Improve the construction accuracy to millimeter level。

Topcon 3D mmGPSSpreadingCharacteristics of the control system

One、Non-pile paving

There is no need for surveying personnel to carry out field survey, pile setting and erection of reference datum line.,Reduce working procedures such as hanging wires and erecting beams on site,Reduce the input of auxiliary personnel,Make field management more efficient,Improve security。

Two、All-weather construction operation

The system control box screen displays the current construction status,Easy to understand,And is convenient for an operator to view,Construction conditions are not affected by light.,24 hours of all-weather continuous construction operation。

Three、Elevation accuracy at the millimeter level

Millimeter-level elevation control accuracy,Provide high-precision elevation datum for the whole construction process,Avoid waste of quality materials。

Four、Domain laser(LaserZone)Technology

Based on Topcon laser technology,Single-station area laser transmitter,Can be realized at 10m(High)*300m(Radius)Within the area are all the domain laser receivers.(On the PaverPZS-MCAndmmGPSOf the mobile stationPZS-1)At the same time, millimeter-level domain laser signals are provided.。

Five、1+NWorking mode,Good sharing of benchmark data

Different from Topcon's previous generation of full-station ceremony 3DThe paving system is the original one-to-one working mode.,Topcon 3D mmGPSThe real-time data sharing mechanism is adopted for the control benchmark of the paving system.,Single Field Laser Transmitter andGNSSThe base station can provide multiple devices with high-precision 3DLocating signal,That is, 1 is supported+NThe working mode of,Significantly improve the efficiency of field benchmark data utilization and ease of operation,And minimize the number of stations and human errors between different benchmarks.,At the same time, the investment of professional equipment and professionals will be significantly reduced.。

Six、The system compatibility is good

Topcon 3D mmGPSPlug and Play Design of Paving Control System,No need to change the hydraulic system of the machine,It can be directly compatible with all Pavers of domestic and imported mainstream brands on the market.,And any Paver manufacturer does not need to open an authorization code separately.。

Seven、Control of the whole process of paving operation

Combine 1+NThe working mode of,Topcon's millimeter-class mobile station can easily realize the whole process control of the whole paving operation.。The digital model of the road design can be checked in advance,Real-time inspection during paving and re-inspection and acceptance after paving,So that that quality control of the whole construction proces is realized,Real-time control of paving quality。

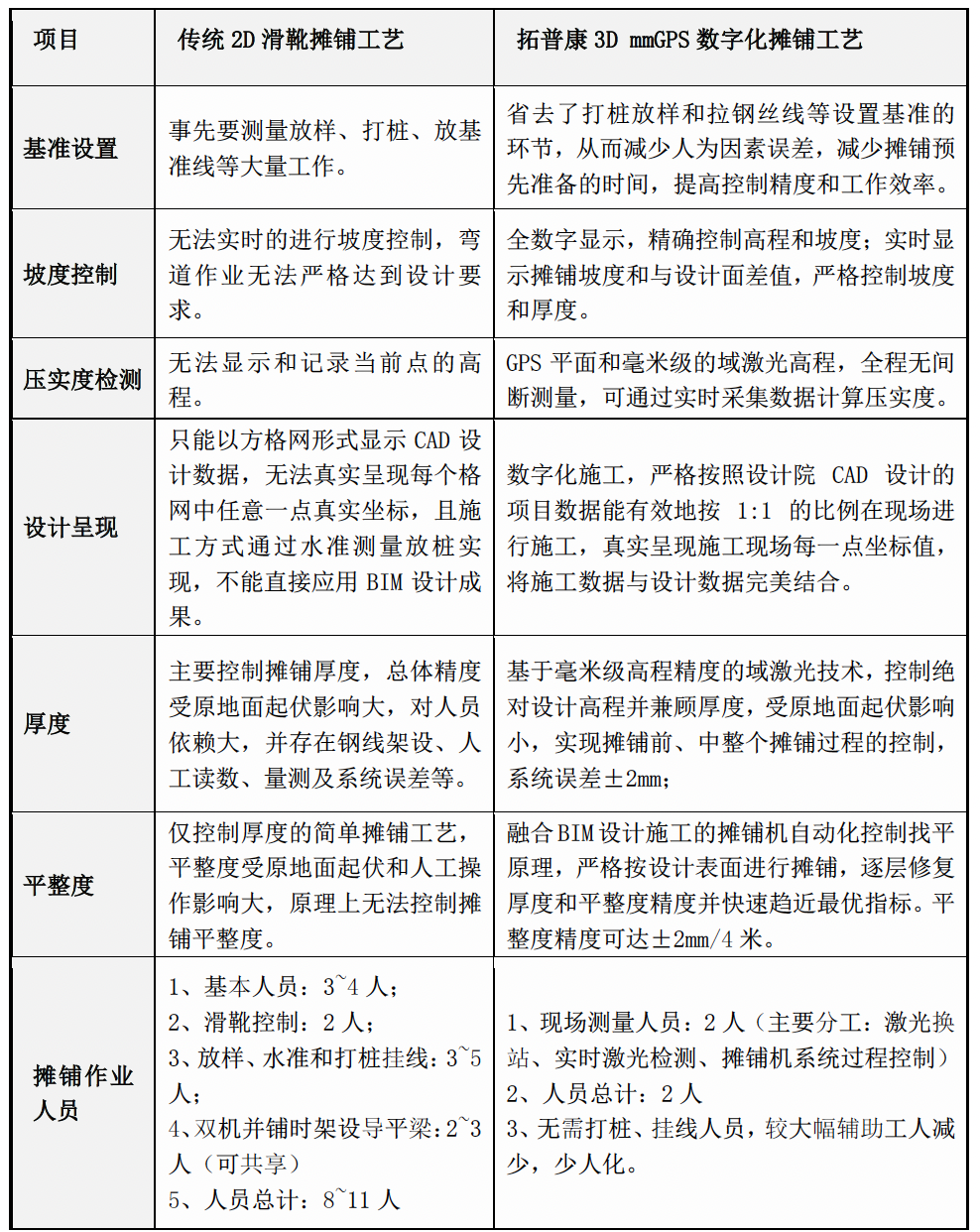

Topcon 3DPaving systems andComparison and Energy Efficiency Analysis of Traditional Slipper Technology

System implementation steps and key points

1、Layout of control network:

Plane Control(X、Y)Easy use of existing control points,Coordinate transformation parameters established during early road construction shall be used as much as possible.,To ensure the relative uniformity of accuracy compared with the previous construction、Eliminate mutual differences,These data can be directly imported into the notebook.。It is recommended that the elevation control shall be based on the requirement of Class IV leveling 100mInterval densification benchmark,Facilitates domain laser calibration and verification。The erected laser transmitter is calibrated by two known bench marks.,The error of elevation control accuracy between two points is 2mmWithin,To sum up, the main points are as follows.:1) Coordinate transformation parameters established during early construction should be adopted.;2) Import local coordinates,Collect its longitude and latitude for coordinate conversion;3) Encryption level according to grade level,Layout of precise elevation control network。

2、BIMConstruction modeling:

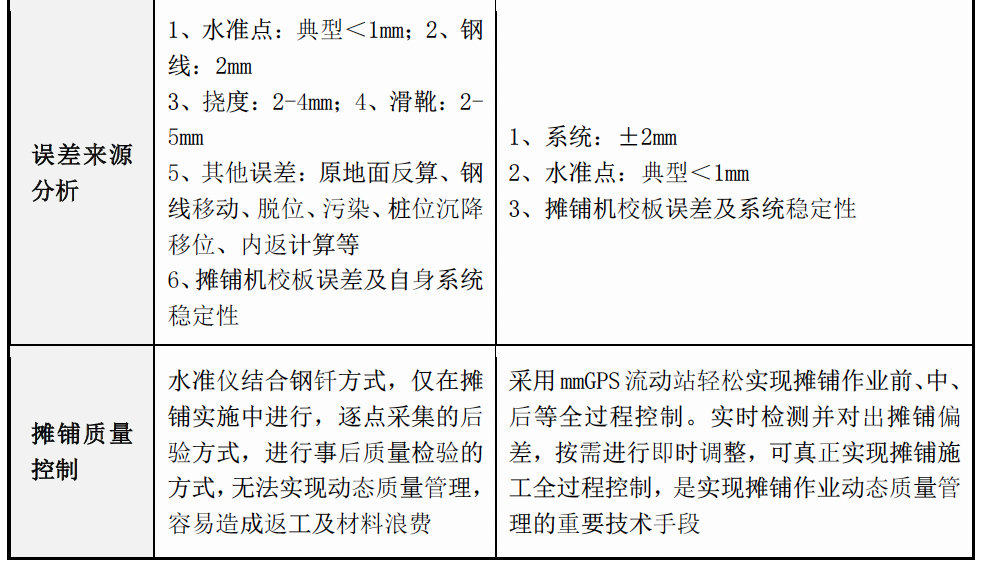

Officially in progress 3DBefore digital construction,Must complete 3DDigital modeling isBIMConstruction modeling,For the highway,Two approaches are commonly used for modeling。

Curve feature method modeling,Modeling according to the curve elements provided by the design Institute,Present all mainlines exactly as designed、Ramp and other sections,The advantage is full compliance with the design data;The disadvantage is low flexibility.,Partial adjustment is not possible。

Pile point method(Coordinate method)Modelling,Modeling according to fixed interval coordinate point position information,The advantage is high flexibility.,Can be adjusted according to the needs of the site;The disadvantage is that there will be a very small error between the two pile points and the design data, and the workload of data entry is large.。

BIMAfter the construction model is established,It also needs to be based on the existing control network.,Adopt system supportingmmGPSMobile station to pre-paved lower bearing layer,YesBIMSuitability check of construction model,Necessary adjustment shall be made as required or the lower bearing layer shall be treated in advance.,To check the accuracy of the coordinate control network relationship,While ensuring thatBIMApplicability of construction model, etc.。

3、Mechanical performance inspection before paving:

Basic inspection of the mechanical performance of the Paver before paving,O as to ensure the stability and smoothness of the automatic paving construction process control.,The contents that need to be checked are listed as follows:

Make surePZS-MCField laser receiver is firmly fixed;

3D-MCSystem correction of dimensional parameters in airborne control software;

3DPaving System Control Paver Hydraulic Cylinder Sensitivity Calibration;

Determine according to the scale value and position corresponding to the loose laying thickness;

Paver screed check plate check( No seesaw at both ends、No arching in the middle)Etc。

Summary of system application

Compared with the traditional construction technology,,Topcon 3DThe paving construction does not need to erect the steel wire rope and invert the aluminum beam ,Minimize personnel input and intervention,Save labor cost and improve on-site safety management level。3DThe paving operation further improves the material utilization rate.,Avoid waste;The application of the system is not affected by light conditions.,Capable of 24-hour continuous operation,It is an important technical guarantee to effectively promote the construction period of the project.。

Application 3 of this projectDThe effect of quality improvement of paving system is remarkable.,The flatness of the water-stabilized base is controlled at 5mmWithin,The mean square deviation is less than 1.2;The project along Taihang Expressway adopts the world's leading 3DPaving control system,It really came true“Automation and efficiency”、“Digitalization and quality improvement”And“Intelligent personnel reduction”,It's a positive response“Build a strong transportation country”An important move,But also that implementation of this project.“Ping An Centennial Quality Project”An important manifestation of。

Anyang along the Taihang Expressway is Anyang City.“Fourteen five”Major transportation projects in the period,It is also a construction“Five vertical and six horizontal”An important part of the expressway network pattern,It is also a high-speed corridor to promote the joint development of Henan Province and Beijing, Tianjin and Hebei.。After the completion of the project, a fast passage will be formed at the eastern foot of the Taihang Mountains.,Yes, perfect Yu、Jin、Road network structure in Hebei region,Promoting coordinated regional development,Accelerating the Rural Revitalization of South Taihang,It is of great strategic significance to promote the development of resources and tourism along the line.。

Contribution:Anyang Section along Taihang Expressway of the Fourth Company of CCCC Second Highway Engineering Co., Ltd.YASG-2 Project Department