Bao'e CSM double-wheel milling and deep mixing was successfully embedded in andesite, and the waterstop curtain project of Tianshan No.1 Road Station of Qingdao Metro was successfully completed

June 13, 2023Recently,You Bao'eCSMThe waterstop curtain project of Tianshan No.1 Road Station of Qingdao Metro Line 15 was successfully completed with the participation of double-wheel milling and deep mixing equipment.。

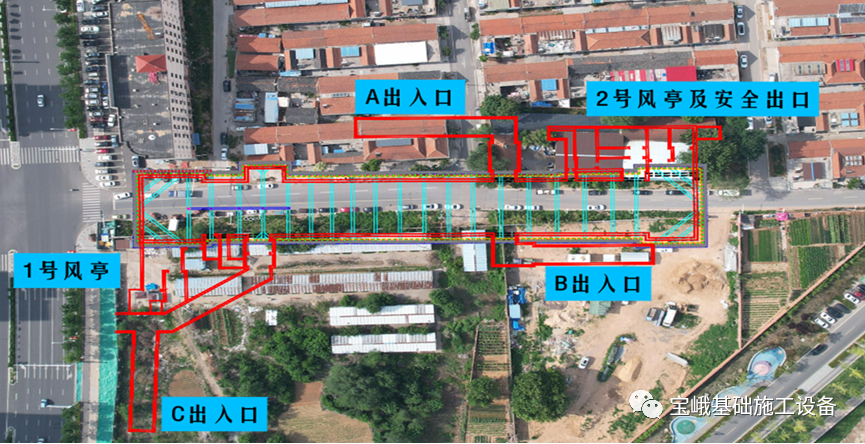

Tianshan No.1 Road Station is located in Tianshan No.1 Road and Planning Xincheng No.2 Road in Qingdao City.,Laid along the planned Xincheng No.2 Road,East-west arrangement,In the long term, it will be an underground three-storey island platform station for transfer with Line 23.。The length of the foundation pit of the main structure of the station is about 159.8 m,About 24 in width.3-29.3 m,Approximately 29 deep.5 m。The overall structure of the foundation pit is constructed by open-cut method.,Use cast-in-place bored pile to hang feet+Anchor cable support,Steel pipe piles are used at the lower part+Anchor cable+Bolt support;Waterstop curtain of foundation pit shall be adoptedCSMDouble-wheel milling and deep stirring proces。The project is contracted by China Construction Port and Navigation Bureau Group Co., Ltd.,The project department“Build a world-class subway”Deploy for work,With“No seepage and no leakage”Is the quality objective,Careful planning in all aspects,Comparison and selection of construction units and construction equipment。The following figure shows the entrance and exit planning and surrounding environment map of the proposed Tianshan 1st Road Station.。

Tianshan 1st Road StationCSMWaterstop curtain by Tianjin Jinkan Geotechnical Engineering Co., Ltd.,Adopt Bao'eCSMDouble-wheel milling and deep mixing equipment for construction,Wall thickness 800 mm,Maximum design depth 25.1 m,Total 166 slot sections,Double-wheel milling sleeve milling joint process is adopted。Strata penetrated by waterproof curtain construction include:Plain fill、Silty clay、Medium coarse sand、Completely weathered andesite、Strongly weathered andesite、Moderately weathered andesite,Final embedment in slightly weathered andesite。The following figure is a typical geological section of the project.,The bedrock at the bottom is andesite.。

CSMThere are four difficulties in the construction of waterproof curtain:1. The upper clay layer is easy to paste, drill and wrap mud.,Affect the cutting efficiency;2. The characteristics of the formation make the equipment stuck in the construction process.、Risk of burying drill;3. The buried depth of the stratum fluctuates greatly,Characteristics of unclear interface between soft and hard formation。In order to ensure the water stop effect,The waterstop curtain is designed to be embedded in slightly weathered andesite;4. Due to the requirements of rock entry,Tool wear is large。So,This is for the construction capacity of the equipment.、Understanding of geological conditions、The professional technical level and management ability of the construction unit have put forward higher requirements.。

Tianjin Jinkan Geotechnical Engineering Co., Ltd. introduced the first domestic Bao'e guide rod in the early stage.CSMDouble-wheel milling and deep stirring equipment,The depth of the completed cut-off wall is up to 47 m,A total of hundreds of thousands of square meters of work have been completed.CSMDouble-wheel milling cut-off wall and retaining wall works,On the important technical indicators of the wall,Such as:Coefficient of permeability、Wall strength,All meet the requirements of design specifications.,Have rich experience in engineering practice。

The following picture shows the application of Bao'e at Tianshan 1st Road Station of Qingdao Metro Line 15 by Jinkan Geotechnical Company.CSMDouble-wheel milling and deep mixing equipment is used for rock-socketed waterproof curtain project。

Bao'eCSMDouble-wheel milling and deep mixing adopts crawler chassis,Grooving arrangement and equipment walking、The positions are very flexible.,Configured with up to 100 torque per gearbox kNm,Except for general geological conditions,It can also cut hard soil.、A dense layer of sand and gravel,And strata with certain rock penetration requirements.,Bring further guarantee to the watertightness of the bottom of the wall。The maximum speed of the mixing wheel is 35 revolutions per minute.,Can help stir quickly、Liquefied soil,So that that quality of the for wall is more uniform。The picture below shows Bao'e.CSMMixing wheel capable of cutting hard stratum with double-wheel milling and deep mixing configuration。

BecauseCSMCharacteristics of the process,There is no need to make guide walls in advance.,Can save reinforce concrete consumables and times。Construction process,Make full use of undisturbed soil,The amount of slurry return is small,More material saving、Relatively environmentally friendly。It can be seen from the figure below that there is no need to make a guide wall during the construction of double-wheel milling and deep mixing.、No reinforced concrete construction platform is required.。

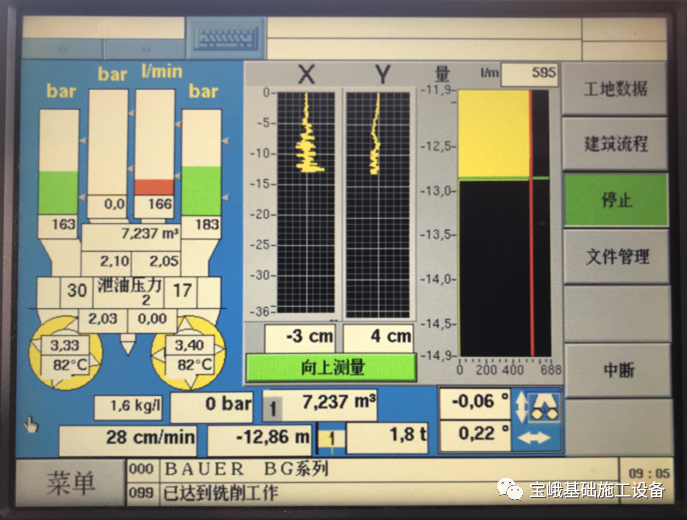

CSMDouble-wheel milling and deep stirring configurationB-tronicSystem,It can help operators to control the verticality of the wall.,Accurately control the injection amount of cement slurry,Ensure that it meets the design requirements。

Tianshan 1st Road StationCSMThe trial construction of the waterproof curtain will begin in late March 2023.,At the beginning of this month, all works were successfully completed.。Due to the proper site management of the participating units,Construction technicians、Solid and reliable professional ability and professionalism of operators,Reasonable construction measures are taken.,All the above difficulties are overcome.,On the premise of ensuring the construction quality,And that construction efficiency is improve,Finally, it was successfully completed under the difficult geological environment in Qingdao area.CSMDouble-wheel milling and deep stirring waterproof curtain engineering,It also provides the guarantee of the construction period for the later excavation of the foundation pit.。