Jungheinrich builds new logistics warehouse for Hawle Armaturen in Freilassing

July 12, 2023• Full-automatic warehouse and frame integrated warehouse,Five laneways have more than 15,000 shelf storage locations

• Provide one-stop solution,From Steel Rack Systems to Warehouse Management Systems (WMS)

•Provided by Jungheinrich“Tailored solutions”And full service

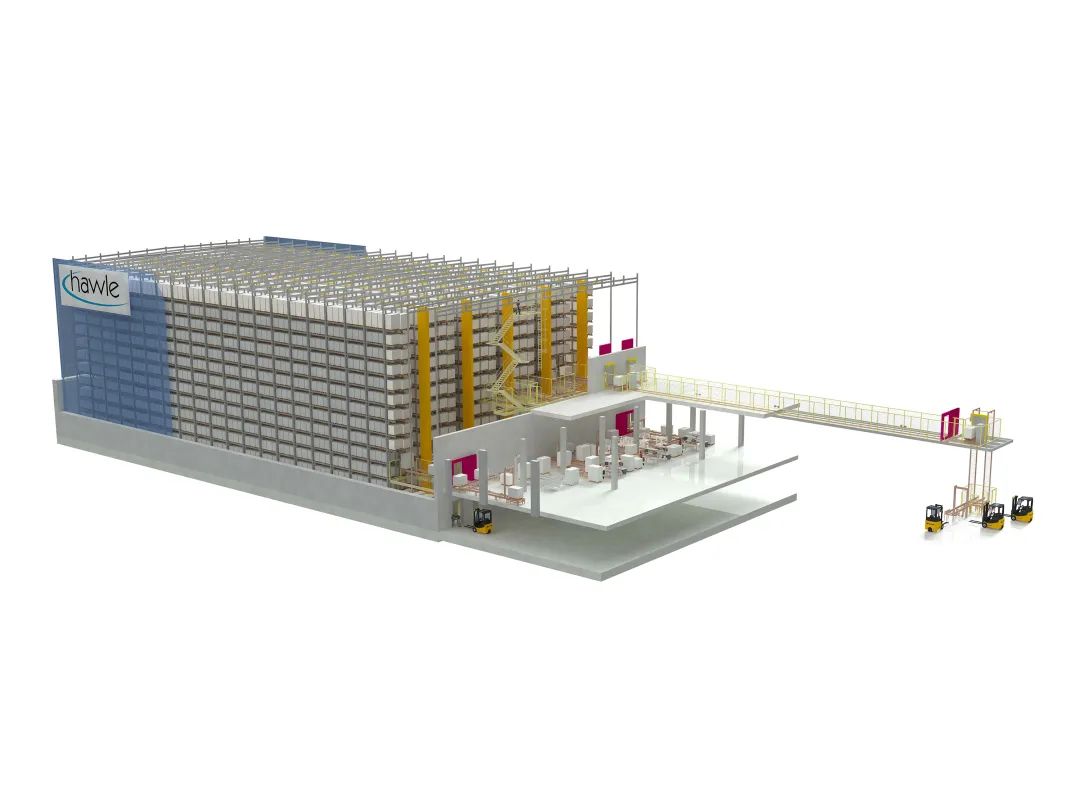

Hamburger,July 6 – Hawle Armaturen GmbHThe company is a manufacturer of heavy-duty valves for municipal water and sewage management and gas supply.,Commissioned Jungheinrich to build a new logistics warehouse。HawleHeadquarters is located atFreilassing,It is planned to build a fully automatic integrated warehouse by October 2024.,Over 15 in five aisles,000 shelf storage locations。The warehouse is planned as a greenfield project.,Will replace Hawle Previous manual distribution center。This will make in Germany、Group companies with bases in Europe and the United States are able to position themselves for more business growth。

Project Planning CompanyMaier IntraplanGeneral manager Hans-Joachim Maier Explains why the company chose an in-house logistics specialist in Hamburg:

“

Jungheinrich with tailored solutions,And a high degree of commitment to meeting customer requirements,This won our favor and confirmed our choice.。

”

Hawle Armaturen GmbH The general manager of Thomas Bohl Added:

“

At first, the two sides were attracted to each other.,Therefore, it can be opened.、A productive exchange。The eternal force left a deep impression on us.,As a provider of one-stop solutions,From steel racking systems to Stackers,To the control unit andWMSSoftware,Everything you need。

”

Ergonomic order picking

The finished products produced will be stored in the integrated warehouse.(72x35x25 meters)。These shipments will then be order picked in a fully automated manner。The conveying system is connected with the production line through the corridor.。The conveyor system is connected to the manual storage area on the ground floor of the warehouse。Goods received,Raw materials and semi-finished products will be temporarily stored here.。Chain conveyor systems are used to transport storage cages as well as materials weighing up to 1,200 kg European standard pallets and special pallets。This ensures very smooth and safe operation of the different Vehicles。Incoming station and six order picking stations with ergonomic lifts are located on the ground floor。

Jungheinrich's scope of supply includes not only the integrated warehouse(The roof and the side wall panels are tightly integrated with the goods rack),,Also includes five withSPSAnd a Stacker with visual functions.,And a complete conveyor system with six order-picking stations。Hawle ArmaturenAt the same time, it has purchased the eternal power for automated warehousing and material flow management. WMS(Warehouse Management System)。Eternal powerITExperts are on the spot.ITDetailed preliminary analysis of the processHawleIt left a particularly deep impression.。