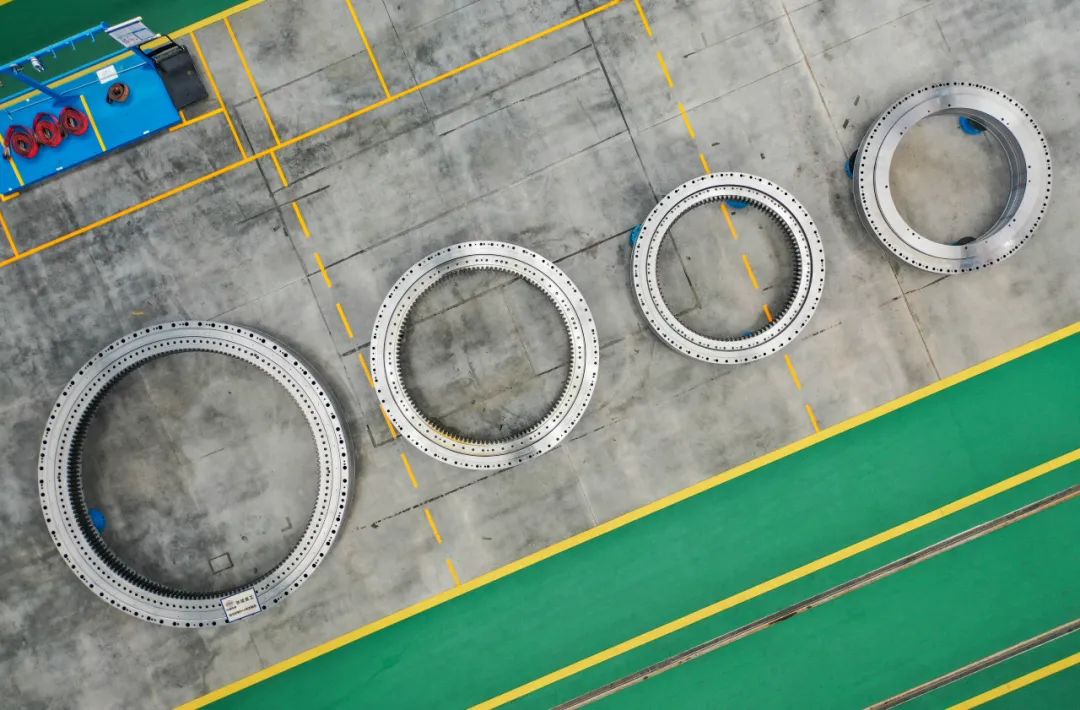

Leading the industrialization development of roadheader main bearings, the roadheader main bearings of various specifications of Railway Construction Heavy Industry have entered the stage of batch application.

August 01, 2023

The other day,The main bearing of multi-specification Roadheader independently developed by China Railway Construction Heavy Industry Co., Ltd. has been verified by working condition simulation test.,It has entered the stage of batch engineering application.。

Key technologies need innovation urgently

TBM is a high-end equipment in the field of tunnel construction.,Undertake rock drilling to open the way、It is an important task to build a major national infrastructure project across rivers and seas.。The main bearing is the core key component.,Work in underground tunnel for a long time,Its reliability and safety requirements are extremely high.,Once a failure occurs, it is difficult to disassemble and replace.,It will lead to construction paralysis.,Causing huge losses。In the past, domestic main bearings were lack of test and application data support.,Difficult to effectively verify product reliability,It is difficult to promote engineering application.。

Concentrate on tackling key problems Break through the shackles

In order to break through the problems faced by domestic main bearings“It doesn't work、I dare not use it、Won't use it”Three major dilemmas.,China Railway Construction Heavy Industry Co., Ltd“Chisel the road in every mountain、Bridge in water”The spirit of railway soldiers,Give full play to the design of Roadheader、Advantages of understanding the working conditions of main bearings,Combined with construction application experience,Collecting complex working condition load data,Carry out targeted research and development to tackle key problems by matching the characteristics of working conditions,Break through the high-performance material of main bearing、Highly reliable design、High precision manufacturing、Key core technologies in the whole life cycle such as high confidence test,Reproduced main bearing in soft soil.、Hard rock、Working condition simulation test under soft and hard uneven geology,The system verifies the long-life service capability of the self-developed main bearing to adapt to complex and harsh working conditions.,It has laid a solid foundation for the batch engineering application and industrial development of domestic main bearings.。

Facts speak and move forward bravely

In promoting the application of domestic main bearings in engineering,China Railway Construction Heavy Industry Co., Ltd.,Speak with technical strength and test data,In stages、Steadily promote the application of domestic main bearings in batches,More than 20 kilometers have been excavated in typical and representative projects.,Application locations range from coastal cities to the Midwest.,Including Beijing、Shanghai、Shenzhen、Changsha、Xuzhou、Nearly ten provinces and cities such as Inner Mongolia;Application Scenario Coverage Shaft Exploration、Oil Pipeline、City subway、Pumped storage and other key projects;Application geology covers unstable soft rock formation、Composite stratum with uneven hardness and high pressure fluctuation and full-section hard rock stratum。Especially in the prime name“Geological Museum”The Pearl River Delta region,Overcome 130MPavery hard granite、Multi-section large-burial depth upper-soft lower-hard stratum、As well as the multiple tests of harsh geological conditions such as high-pressure and frequency-dependent strata in long tunnels.,Successfully realized the target tunnel project section through.,The reliability and stability of the domestic main bearing are fully verified.。

Independent development and mass engineering application of domestic main bearings,Breaking the domestic long-standing discussion“Domestic main bearing”The inherent concept of discoloration,In order to solve the core components of Roadheader“Stuck in the neck”The problem provides firm confidence.,It provides a strong guarantee for the safety and high-quality development of the tunnel Boring Machine industry.。