Orders continue to be busy in production | Many super-large diameter shield machines are concentrated on the line, and China Railway Construction Heavy Industry has pressed the "fast-forward key" for intelligent manufacturing of heavy equipment

September 05, 2023September,

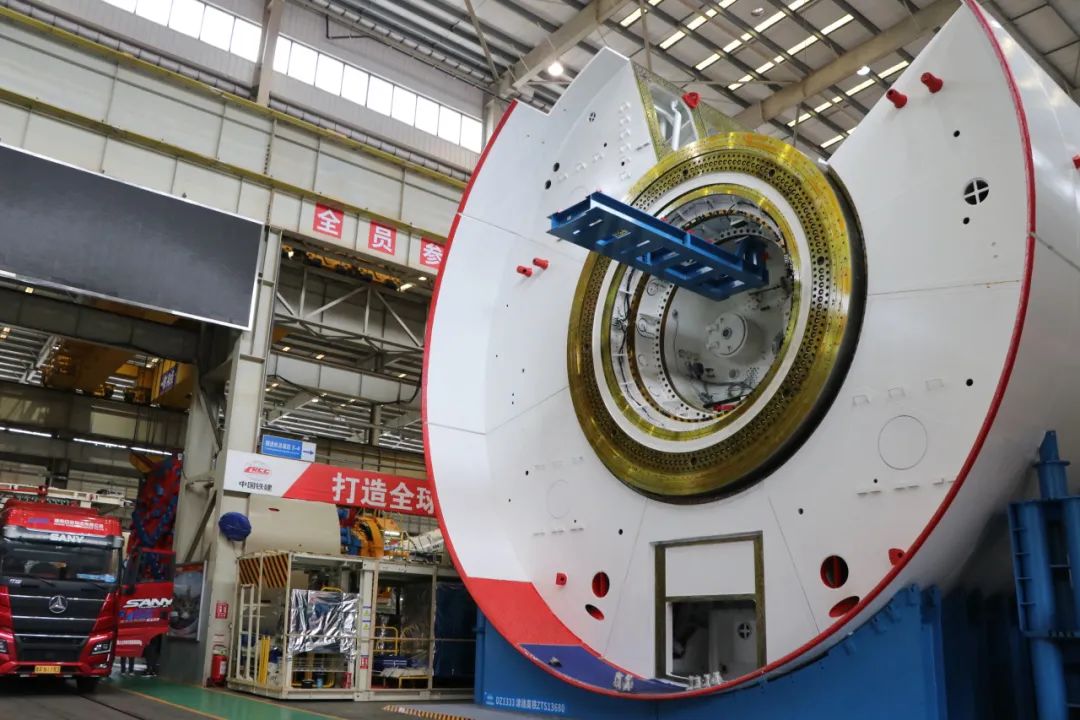

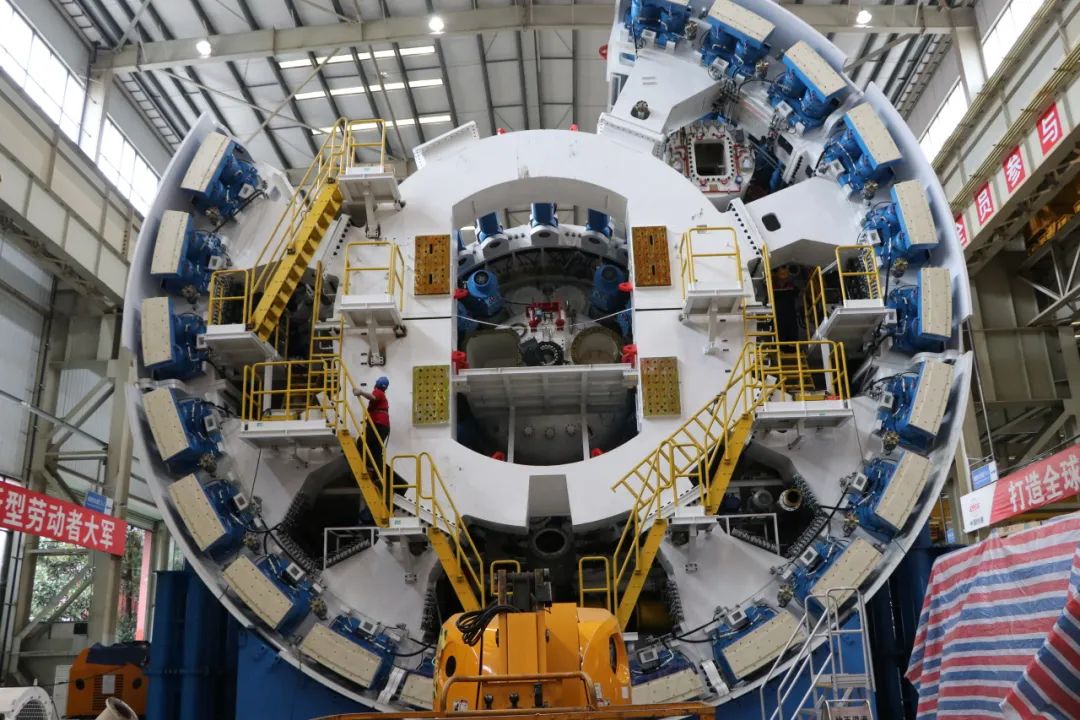

Tiejian Heavy Industry ushered in the intensive production period of super-large diameter Shield Machine,

Many large diameter Shield Machines are put into production and assembly at the same time.,

Reach the peak of production in the same period。

Tiejian Heavy Industry Shield Machine Production Workshop

Make so many at the same time.“Underground dragon”,

The cutterhead can be placed together to a height of 100 meters.,

Compared to conventional models,

Production of super large diameter Shield Machine

More productive resources are needed.。

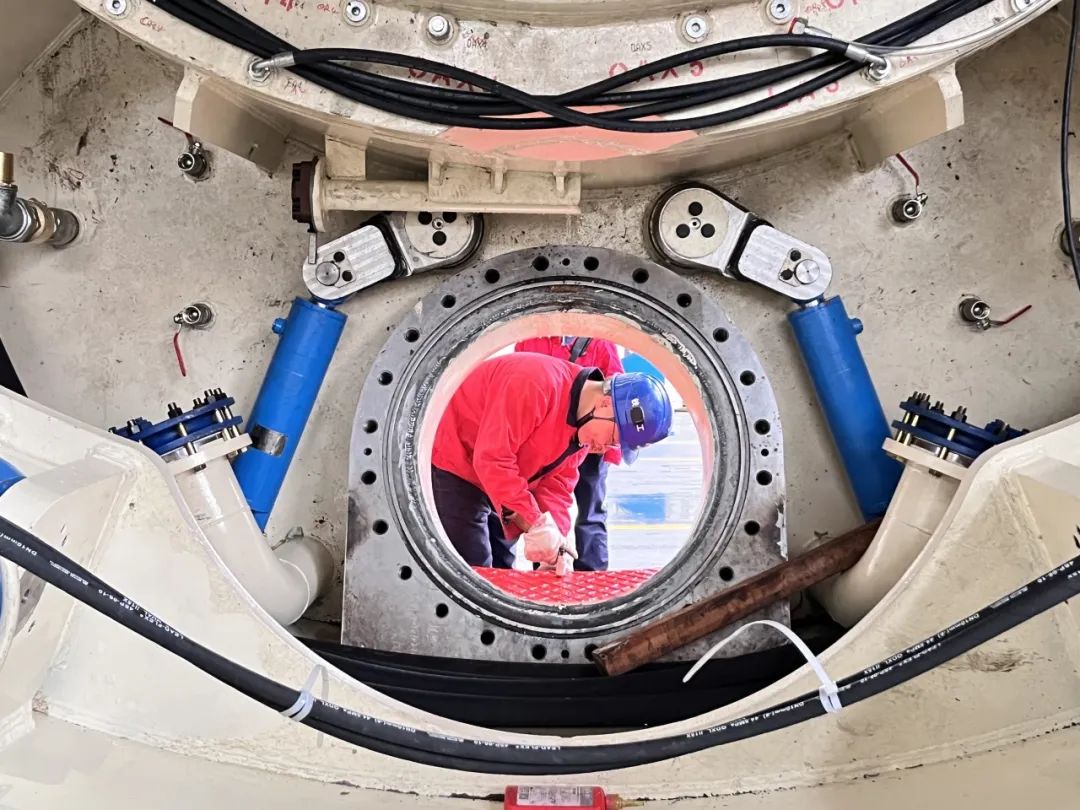

Shield splicing

Disassemble the main drive tooling

Key projects of super equipment services,

Equipment service locations throughout the country。

Verification of erection and positioning datum of front shield assembly

Trolley operation

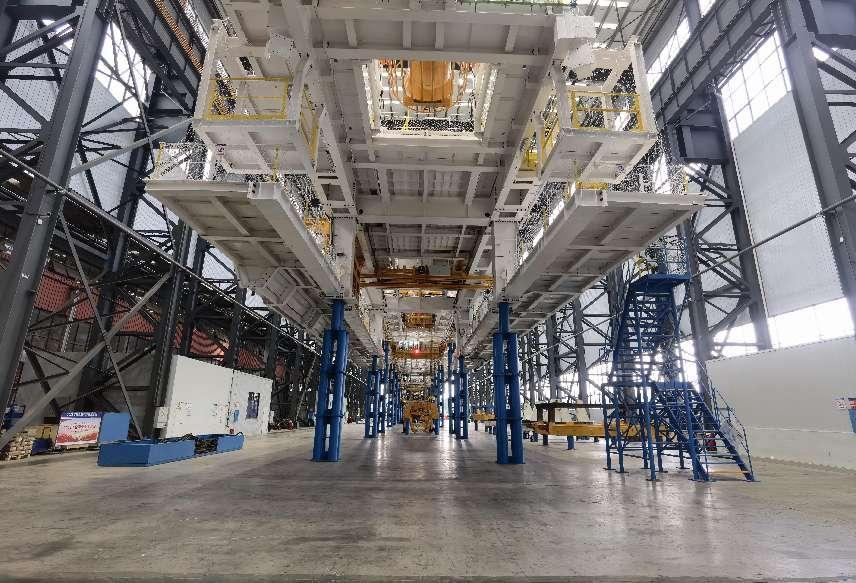

Time is tight、The task is heavy,

Tiejian Heavy Industry Production Workshop“All guns blazing”

I pressed it“Fast-forward key”。

Clear up the plan,Minutiae,

Special person to follow up,

Hundreds of operators unified operation standards,

Stable production。

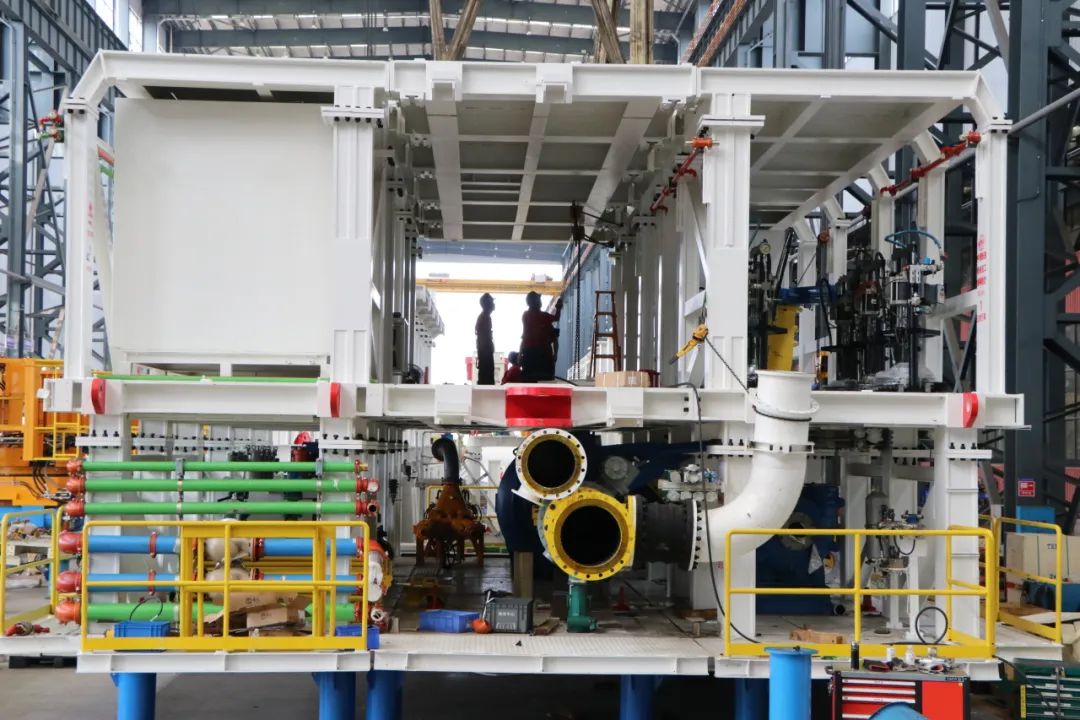

Installation of rear supporting hydraulic valve group

Installation of rear supporting hydraulic valve group

Electrical assembly

A key high-speed rail project in China

A super-large diameter high-speed rail tunnel Shield Machine is needed.,

Excavation diameter 14.8 meters,The total length is 134 meters,Weighing 3,700 tons,

The equipment uses a number of the latest technologies.,

It will be the first time to explore the autonomous tunneling mode of Shield Machine.。

At present, the equipment has been disassembled and packed in the factory.,

Soon to be delivered to the project,

Help the high-quality construction of the project。

The equipment is matched afterwards

Another key high-speed rail project

In the stage of final assembly and erection。

The equipment is in the process of tunneling

Need to cross the seismic fault zone、Soft soil seismic subsidence、

Liquefied layer and other unfavorable geology,

Construction environment can be used

“Long”“Big”“High”“Risk”Summarize in four words。

In view of the key and difficult points of the project,

Railway Construction Heavy Industry has carried out a series of targeted intellectualization.、

Innovative design,

And greatly improves the adaptability of the equipment.,

The construction efficiency can be greatly improved.,

Ensure safety and efficiency。

Shield body of Shield Machine

During the production process

Technical quality personnel

Unified process standards、Enhance quality awareness,

Formulate key and difficult points of assembly、

Key quality control points“Minefield table”,

Carry out targeted tooling design,

Evaluate optimization details,

Conduct exchange training,

Effectively guarantee the lifeline of products。

Front and middle shield cloth tube

Go all out、Gathering potential is sufficient。

Coordination and linkage、Close cooperation。

The production workshop of Railway Construction Heavy Industry is full of vitality.,

Constantly compose the manufacturing speed of heavy equipment in big countries。