The Liebherr RL full range of offshore platform cranes will be carried on the UNK1 of the LNG ship (FLng) for the development of offshore gas fields.

October 17, 2023The oil and gas industry is undergoing a transformation.。The development of natural gas resources in subsea gas fields will help meet the growing global demand for natural gas.。With the exploitation of natural gas、Construction of floating facilities for liquefaction and storage,The demand for compact cranes is also increasing.。Since its establishment in 2012,Wison has become the leading enterprise in the field of floating natural gas application in China.。

As a leader in monetizing natural gas,Manufacturer WisonIt has been decided to buy five new ones.RLSeries crane。The investment is a natural gas liquefaction plant that has been under construction since early 2023.(FLNG)Part of。It is the largest the company has built to date.FLNGFactory,Eni, an Italian energy company(Eni)Commissioned construction。RLAll cranes in the series will supportFLNGMaintenance and supply of plant。The ship is 380 meters long.,The 60-meter-wide ship will be anchored in 40 meters of water off the coast of the Republic of Congo.。

Global Application Manager, Liebherr Universal Offshore Crane

Stefan SchneiderExpress:

“We use the wholeRLThe series convinced Wison,This is both a success.,It is also the driving force for Liebherr to continue to adjust its offshore product portfolio according to market and customer needs.。With Liebherr(China)The company's contract and the cooperation of the service partner are particularly important factors in finalizing the contract.。They will be under construction.FLNGSupport this process during the period。After being put into use,The local office covering the Republic of the Congo will take over。”

Optimized Design Makes Crane Control Reliable and Flexible

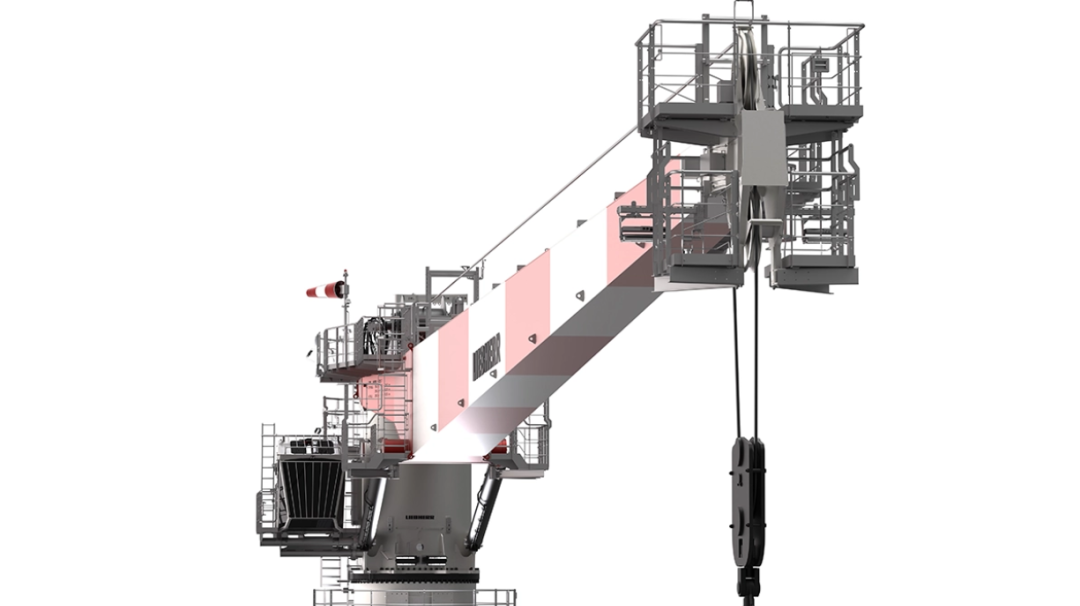

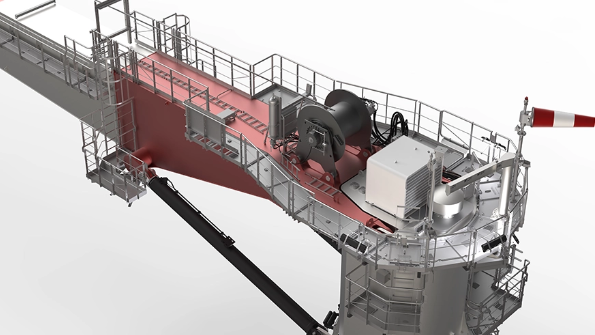

LiebherrRLSeries cranes are compact in construction、Weight optimization,Due to a well thought out design,Even when space is limited,Can also be used in an optimal manner。This can be achieved by optimizing the overall height of the、The smaller tail radius of gyration and the absence of a machine room。The crane also provides an advantage to the operator。The redesigned 7 cubic meter large cab is ergonomic.,Ensure low fatigue work。

Its modern equipment has good surrounding visibility.,The new driver's seat is combined with a new operating concept,Includes new control system and improved air conditioning,Ensure safe operation of the crane。

“ForFLNGEquippedRLSeries can create overall value。Work capacity is enhanced by the highest safety standards and state-of-the-art working conditions。For us,The cooperation with Liebherr means that we have a global crane manufacturer at our side.,Their expertise sets the global standard。”

Mr. Zhang Shouyue, Deputy General Manager of Wison Offshore Engineering Project Management Department

Comment on this collaboration。

Global network ensures reliable service

“The new floating unit can store more than 180,000 cubic meters of LNG and 4..50,000 cubic meters of liquefied petroleum gas。The crane mounted on the platform is part of the integrated service architecture。The global Liebherr network of experienced engineers can supply spare parts in the shortest time and provide the best service.,Thereby ensuring the productivity of the plant。LiebherrRLThe modular design concept of the main components of the series is a distinctive feature.,The interchangeability of the added components is again highlighted。”Liebherr(China)Marine crane sales manager Yang Dong said.。

RLThe crane series has further special features。Innovative chassis inside the rotating column,It's the first in the world to safely dissipate explosive pressure.Ex dExplosion-proof chassis。EXpressureIs a partner of LiebherrR. Stahl AGDeveloped。RLSeries can also be usedLiMain,It's kind of all digital.、Remote control and semi-automated maintenance system。Its modularity with independent packages allows users to be independent of time in the future.、Maintenance of sites and resources。

The planned delivery time of the 5 full explosion-proof cylinder luffing cranes ordered this time is 2024.-2025。

About Wison(Nantong)Heavy Industry Co., Ltd

Wison(Nantong)Heavy Industry Co., Ltd(Subsidiary of Wison Offshore Engineering)Is a leading provider of clean energy technology services and solutions,Dedicated to providing the energy industry with highly integratedEPCICSolution,Including floating LNG facilities、Modular LNG Plant、Floating gas-to-electricity facility、Floating wind and other clean energy solutions。Based on a record of successful project delivery,The experienced Wison team applies its expertise in technological innovation and two world-class shipyards,Provide the highest international quality and safety standardsEPCService。

AboutLiebherr-Offshore Technology Rostock Co., Ltd

Liebherr-Offshore Technology Rostock GmbH is one of Europe's leading manufacturers of marine solutions.。Product range includes ship crane、Mobile wharf overhead crane and offshore platform crane。Front crane and container crane components are also included in the product portfolio.。