Comprehensive Training and In-depth Analysis — Case AF4000 Series Harvester Technology Successfully Completed

November 30, 2023Q How to master Case systematically and comprehensivelyAFTechnical knowledge of 4000 series Harvesters?

All in technical training。Recently,The professional technical training teachers of Case Harvester have carried out training for technicians.。The training focus covers the structure of the Harvester、Electrical system、Hydraulic system、Post-processing system,In-depth analysis of typical fault cases。In-depth explanationAFKey Technologies of 4000 Series Harvester,Further consolidate the comprehensive knowledge system of technical personnel。

01Analysis of Harvester structure

First,The training content focuses onAFStructure of 4000 series Harvester。The trainer gave the trainees a detailed introduction to the operation flow and power flow of the aircraft.。From cutting to throwing mechanism,To enable the trainees to have a deep understanding of the design and operation principles of mechanical structures,So that that harvest regulation method for the field operation of the Harvester can be bet mastered。

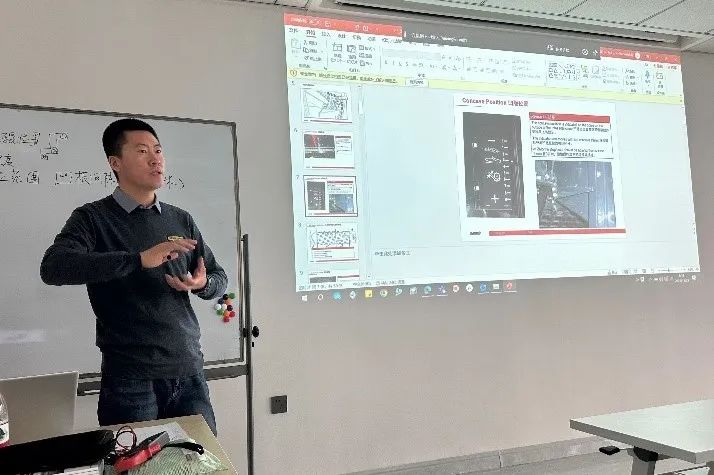

02Interpretation of Electrical System Technology

In the Electrical Systems Training Module,The trainer deeply analyzed the electrical system of the Harvester.,Including the main control unit、Sensor networks and automated control functions。During the training process,Trainees pass the simulated fault,On-board actual measurement and diagnosis,Gain a comprehensive understanding of the electrical system,Provides a foundation for routine maintenance and troubleshooting。

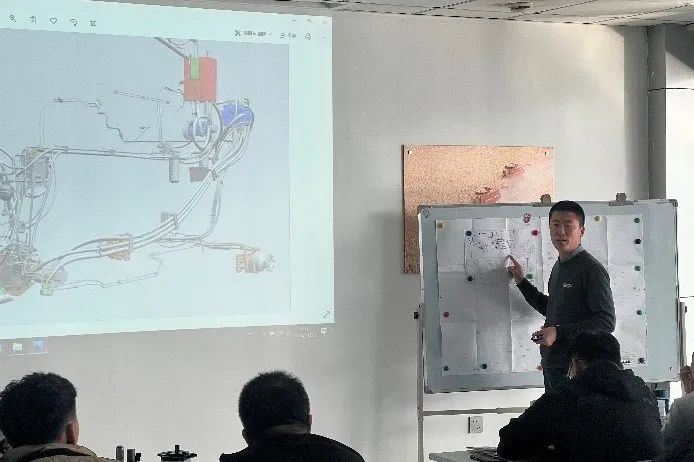

03The hydraulic system operates、Testing and diagnosis

Hydraulic system is the key power transmission and control system of the Harvester.。This training session highlightedAFWorking Principle of Hydraulic System of 4000 Series Harvester,Includes a hydraulic pump、Hydraulic Valve,And the performance advantages of the system。

The training combines theory with practice.,So that every student can get started.,Complete the hydraulic system test independently、Adjustment and related diagnosis。

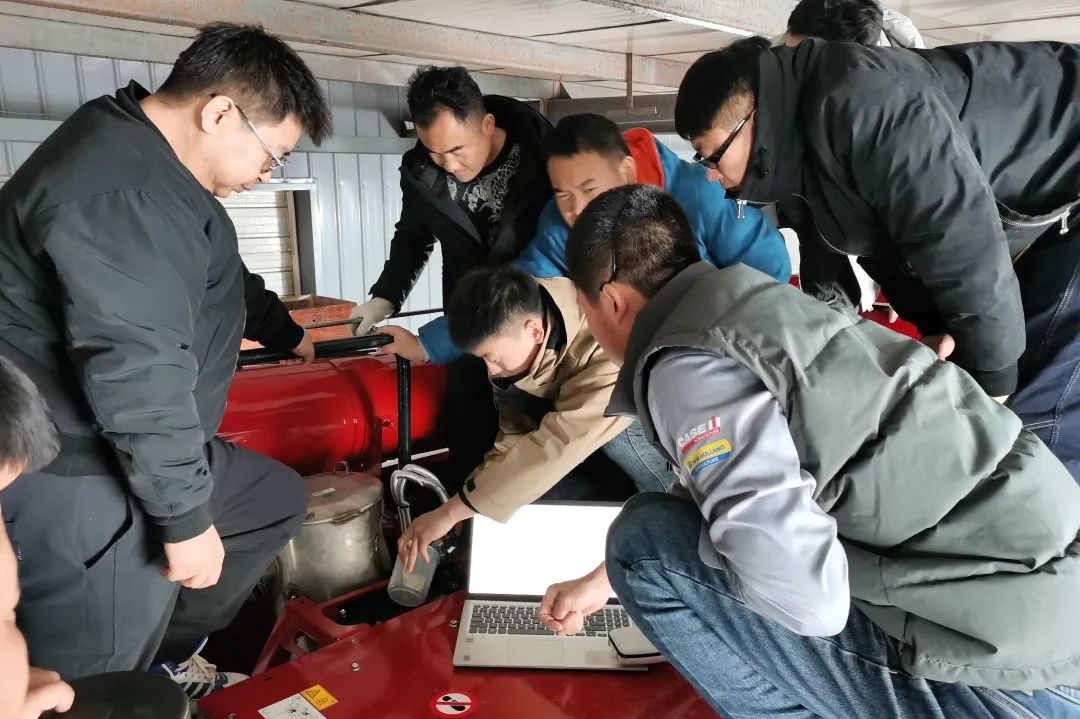

04After-treatment system test

The training further introducedAF4000 Series Aftertreatment System,The importance of tail gas treatment and thermal management strategy is emphasized.。The maintenance and diagnosis of aftertreatment system is very important to technicians.,Can meet the environmental protection standard and improve the efficiency of the machine.。

05Typical fault case analysis

The last part of the training focuses on the analysis of typical fault cases.。Through the in-depth study of the actual case,Trainees can better understand and grasp the challenges they may encounter in daily operation.。By analyzing these cases,,Technicians can learn troubleshooting methods and techniques.,Improve the ability to solve practical problems。

This technical training is for Case.AF4000 Series Harvester technicians offer a unique opportunity to learn。Comprehensive knowledge system and practical operation skills,It further consolidates the technical understanding of technicians on this advanced agricultural machinery.,It lays a solid foundation for improving work efficiency and equipment reliability.。