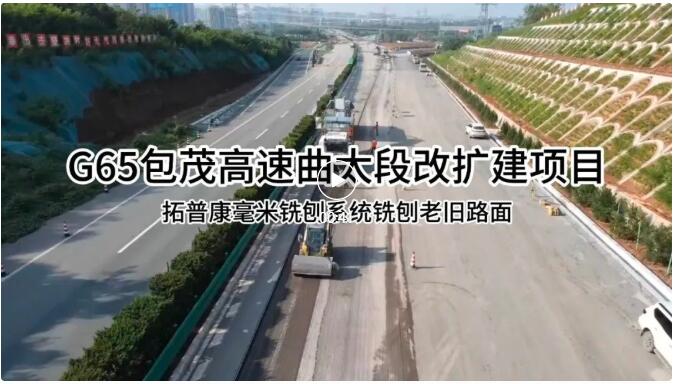

Topcon 3D mm GPS Milling System Helps Qutai High Speed Renovation Project

December 29, 2023Video Appreciation of the Project Site

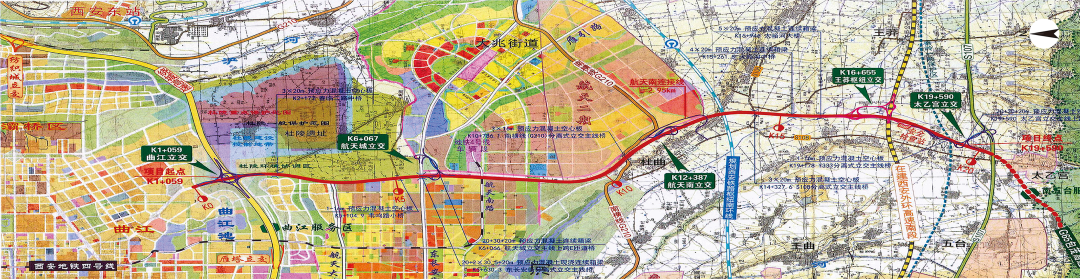

Qutai Expressway is a national expressway.GAn important part of the 65 Baomao Line,It is also the main north-south highway transportation channel in Shaanxi Province.,It belongs to the national key construction project.,It has been listed in Shaanxi Province and Xi'an City“Fourteen five”Plan。The project starts from Qujiang Junction Interchange.,Reconstruction and expansion along the existing expressway to the south by splicing and widening on both sides,End at Taiyigong Interchange,Connect Baomao Expressway to Xi'an(Taiyi Palace)To Zhashui section,The total length of the route is 18.5 kilometers。The project is reconstructed and expanded by widening both sides of the existing expressway.,At present, the project has completed an output value of 6.200 million yuan,Paving of left middle surface course completed,Two-way four-lane diversion,The right side is stepping up construction.。

Construction route diagram

Difficulties in road reconstruction and expansion

The road widening of the project needs to be lapped with the new pavement.,Because the settlement of the new and old road foundations is different,,It is easy to have longitudinal reflection cracks at the overlapping position.,To ensure the quality of lapping,Prevention of Longitudinal Reflection Cracks on Pavement,Usually, it is necessary to carry out step milling on the original emergency lane pavement.,Filling and compacting in layers。In addition, it is necessary to mill the surface structure of the original pavement.,The overall overlay treatment is carried out in the final stage of construction.,Ensure the integrity and driving comfort of the road surface after expansion。

Step milling,Filling and compacting in layers

Difficulties of traditional construction method

Traditional construction methods require surveyors to measure the road surface.,Mark the milling depth according to the new design.。Due to the different degrees of settlement and new design adjustment in different parts of the pavement,Surveyors are required to mark the entire face,Labeling at each position cannot be done manually,Marking can only be done at certain intervals,Unmarked locations are smoothed,It does not really reflect the condition of the road.,In addition, the milling process needs to be controlled by the experience of the mechanical operator.,Construction quality is greatly affected by personnel experience.,There is no guarantee,The whole process will consume a lot of time and manpower.。

MMGPSMilling system

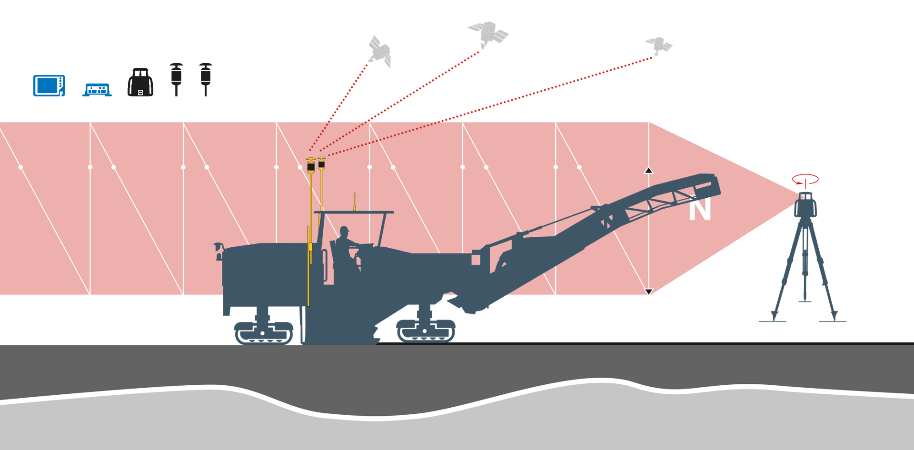

Topcon's 3D mmGPSThe milling system can perfectly solve such problems.,3D mmGPSThe automatic control system of that mil machine consists of a reference station,、Milling Machine airborne equipment and mobile detection equipment.。Wherein the reference station apparatus compriseGNSSReference station receiver andLZ-T5 Domain Laser Transmitter;The airborne equipment includes a laser receiver.、MC-R3 Receiver、Data cable assembly、Display and data link receiving module;The mobile detection device includeGNSS&Domain laser mobile station system。Airborne equipment and mobile detection equipment contain operating software to implement the corresponding functions.,The graphical interface is convenient for operators to control.。

Composition of millimeter milling system

Convert the horizontal and vertical curves of the road into construction curves before constructionBIMModel,During construction,Erected on the control pointGNSSReference stations andLZ-T5 Laser transmitter,WillGPSDifferential signal and laser elevation information via data link radio and cable(Laser elevation information)Transmit toMC-R3 Receiver。MC-R3 After processing the received data,And transmit the three-dimensional coordinate data toGXSeries control box,The control box compares the obtained current three-dimensional coordinate information with the design data in the control box,Generate corresponding elevation correction information,This information is used to control the lifting of the milling drum,O as to mill the pavement meeting the requirements of design flatness and thickness.。At the same time,Can be usedmmGPSReal-time monitoring of pavement milling conditions by mobile station,Real realization of process monitoring construction,Meet the requirements of milling design。

Working Diagram of Millimeter Milling System

Millimeter milling implementation

Milling inspection

Millimeter-level automatic control

mmGPSAdvantages of Milling Machine Control System

01

Pileless milling

There is no need for surveyors to carry out on-site survey and mark piles.,And can be flexibly adjusted according to the requirements of field construction.;

02

Digital construction

Import the design data of the design Institute into the controller when the system is applied,Realize intellectualization、Digital construction,Greatly reduce the use of personnel;

03

Whole process control of construction

Real Time Continuous Control of Milling Process,Display graphics and data information in real time;

04

High precision operation

The system is based on the construction process requirements.,Carry out the construction accurately according to the design,The flatness of the pavement after milling is well ensured.;

05

All-weather construction operation

System construction is not affected by light,24 hours of all-weather continuous construction operation;

06

Humanized display

The system uses the control box screen to display the current construction status.,Easy to understand,And is convenient for an operator to view;

07

And that optimal mil amount is achieved

Controlled by automation,The variable control of the milling thickness can be accurately realized。

Help the construction of Xi'an

By the end of September,The asphalt middle layer of the left main line of the reconstruction and expansion project of Qutai Expressway has been completed.,With the completion of temporary pavement marking,The left side is already open to traffic.,It has laid a solid foundation for the project to achieve the established goals.。The right main line project has been carried out smoothly.,Topcon's digital construction technology will continue to be used for construction.,The project is expected to open to traffic in October 2024.。