Sandvik has once again created the "world's best" in the field of processing.

January 30, 2024The 161-year-old Sandvik,Engrave the Gene of Innovation in the Bone,It has not only developed many new products that lead the industry.,And create again and again.“New record”。

Sandvik took the lead in realizing the mass production of steel in human history.;Led mine electrification and automation;Produced the world's first grooved indexable insert、First chemically coated blade;Made the world's first 3DPrint the guitar;It has released the essence of five artists.、Comprehensive applicationAI、Cutting-edge manufacturing solutions、First-class cutting tools, etc.“Impossible Sculpture”……Lately,We're making another big move.:BuiltThe World's Largest Damping Boring BarSilent ToolsTM。

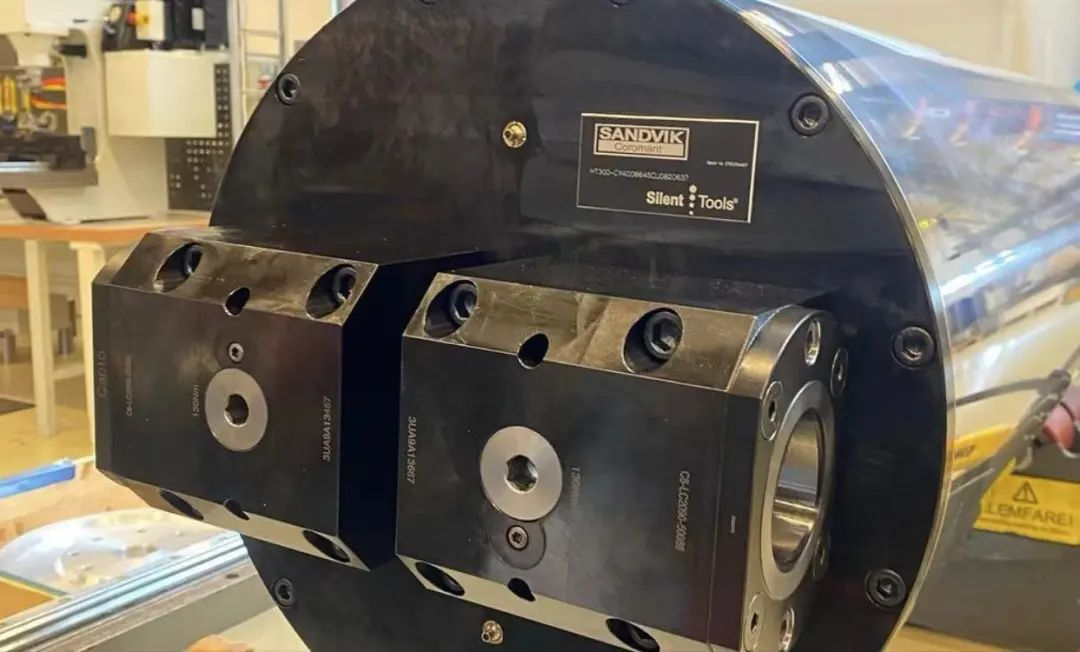

This damping boring bar,Boring bar overhang length up to 11,000 mm(11 m),Diameter 600 mm,Under the Sandvik Group,Manufactured by Sandvik Coromant, the world's leading manufacturer of metal cutting tools。 Below ,Let's take a look at this engineering field with Xiao Ke.“Behemoth”How was it born?。

Origin

Make special parts,Customer needs to customize unprecedented giant boring bar

The boring bar is a Boring Machine/Lathe、Deep-hole drilling and Boring Machine and corresponding drill bit、Boring head、Connecting rod of rolling head and combined boring and rolling head,O as to be suitable for different machine tools.、The need for different machining depths。Offshore oil and gas、The production of precision metal parts in industries such as power transmission and renewable energy requires large lathe tools.,Boring bar plays an important role in it.。

To machine a specific type of part, Finland Häkkinen Group JyväskyläCompany,The existing bottom hole of the part needs to be more precisely bored with a boring bar.、Accurate、High surface quality reaming and finishing。

The diameter and length of the boring bar are determined by the size of the workpiece itself.,In order to achieve the best stability of the processing,The size of boring bar required by customers is unprecedented.。Large size boring bar is very important to achieve boring depth and inner hole turning accuracy,This is not possible with a standard size boring bar。

Häkkinen Group JyväskyläThe company initially turned to a partner based in the Czech Republic.ŠMT,The company is the world's leading high precision horizontal boring and Milling Machine.、One of the manufacturers of horizontal lathes etc.。ŠMTI found Sandvik Coromant.,It is hoped that its help in production can be used forŠMTBoring bar for large lathe,Thus forHäkkinen Group JyväskyläFabricate parts。They want the boring bar not only to reduce cutting vibrations as much as possibly,It should also be able to seamlessly integrate with existing machinery and equipment.,At that same time, break the limit of the existing tur process.。

Sandvik Coromant is a world-renowned manufacturer of boring bars.,ProducedSilent ToolsTMBoring BarFor maximum reduction of cutting vibration,And get the name“Silent” (Silent) ,It is usually used for machining long overhanging tools.。Back in 2015,Sandvik Coromant produced the longest reinforced damping boring bar in the world at that time.,Length up to 6,090 mm(6.09m)。

Facing new customization requirements,Sandvik Coromant in NorwayTeenessThe production team took over this special task with confidence.,The team's history of developing boring bars dates back to the 1960s.,It can be called an industry leader。

Challenge

Damping、Stable、Efficient,All of these functions are needed.!

Excessive vibration of boring bar will affect the machining accuracy of parts.,Cause abnormal tool wear and loss of part integrity。This isHäkkinen Group JyväskyläA major problem in the company's previous large-scale processing.。Sandvik Coromant Czech Project EngineerVaclav FaberExpress:“We want to reduce the cutting vibration through the customized boring bar.,Ensure the accuracy and surface quality of the workpiece.,While increasing productivity、And that service life of the cut is prolonged。”

So,Sandvik Coromant's boring bars are made of steel,Using an approach known as“Damping mechanism”Components of,Vibration-free machining with special damping。At the same time,The front end of that bore barCoromant Capto®Interface,Used to clamp the blade required by the process.。Coromant Capto®Designed to reduce clamping and tool change times,The utilization rate of the machine tool can be greatly improved.,Achieve stable and reliable processing。

“It turns out,The tool interface is particularly suitable for multi-task machine tools. ,It connects cutters of various lengths and design features through modularity.,Regardless of the machine tool interface。Coromant Capto®It also meets the requirements of customers for boring bars.,Fits a variety of tool designs。” Vaclav FaberSay。

Test

Recommended test parameters of intelligent manufacturing software,Make processing more accurate

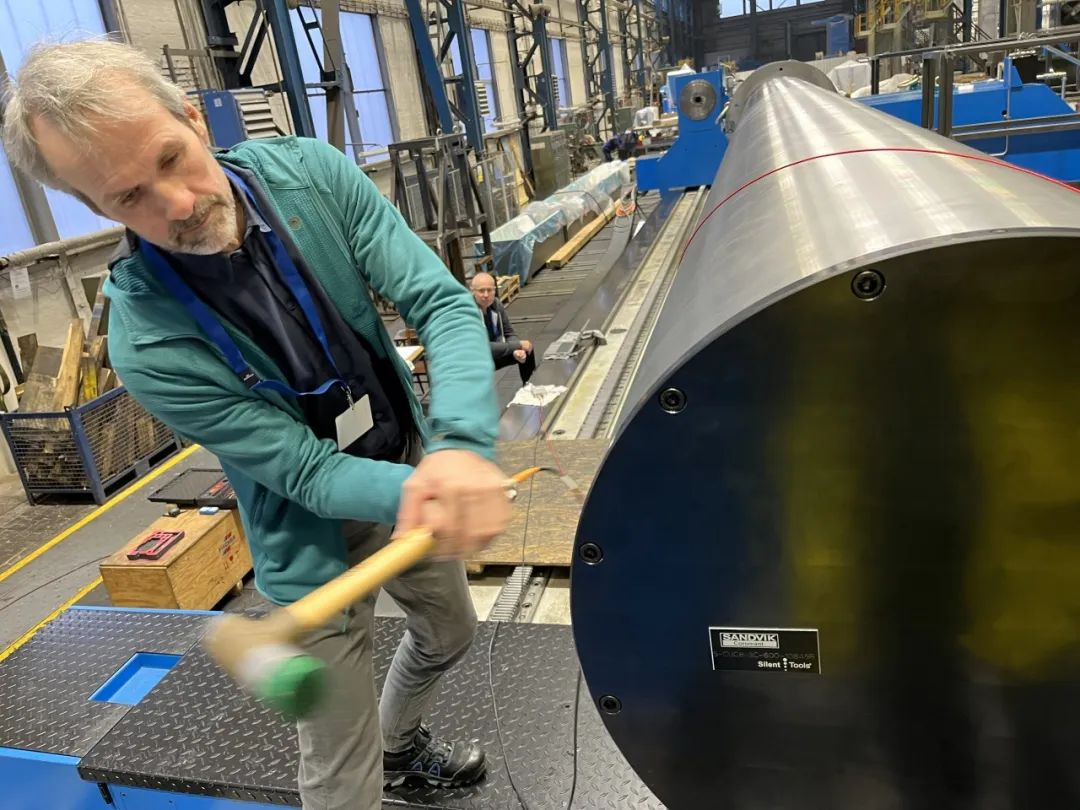

After the giant boring bar is completed,Sandvik Coromant TeenessKey frequency measurements were made on site by the experts of the production team,To evaluate the effectiveness of the damping components integrated in the boring bar。

They install boring bars in largeCNCLathe,Multiple tests with three applications——Rough machining、Finishing and copy turning,Each time a different cutting parameter is used。The tool is tested at 10 times the maximum allowable overhang ratio,At the recommended overhang depth,Minimize vibration and achieve optimum stability and machining accuracy。The round shank type boring bar adopts an open type holding type clamping mode.,The minimum clamping length is 4 times the diameter of the boring bar。

The cutting parameters are based onCoroPlus® Tool GuideInitial recommendations generated by the software platform,And continuously optimize and improve the generation in the test process.。The load on the boring bar depends mainly on the depth of cut (ap)、Feed(fn)And workpiece material。During processing,Be sure to make sure that the appropriateapAndfn,So that that generation of cut vibration is avoided。“Based on test results,We recommend cutting parameters and inserts to our customers.,O as to ensure more excellent processing effect.。” Vaclav FaberExplain that。

At present,The world's largest boring bar has becomeHäkkinen Group JyväskyläImportant assets of the company,Are showing off their skills in the workshop.,Busy processing all kinds of precision machine parts.。Future, ŠMTFurther collaboration with Sandvik Coromant is also planned,Produce more Slightly smaller sizes,High quality boring bar that can be used to machine other parts。

The world's largest boring bar,It not only refreshes the record in the field of manufacturing.,It also proves Sandvik Coromant's ability to focus on innovation and excellence, as well as its high level of professional skills.。Driving the World Forward with Engineering Technology,Sandvik has been working hard.,I look forward to sharing our new record-setting story with you next time.。