Bao'e BCS 125 Groove Milling Machine was continuously and efficiently constructed for 9 months, which helped the successful completion of the continuous wall project of Huacheng Street Station of Guanghua Intercity Railway

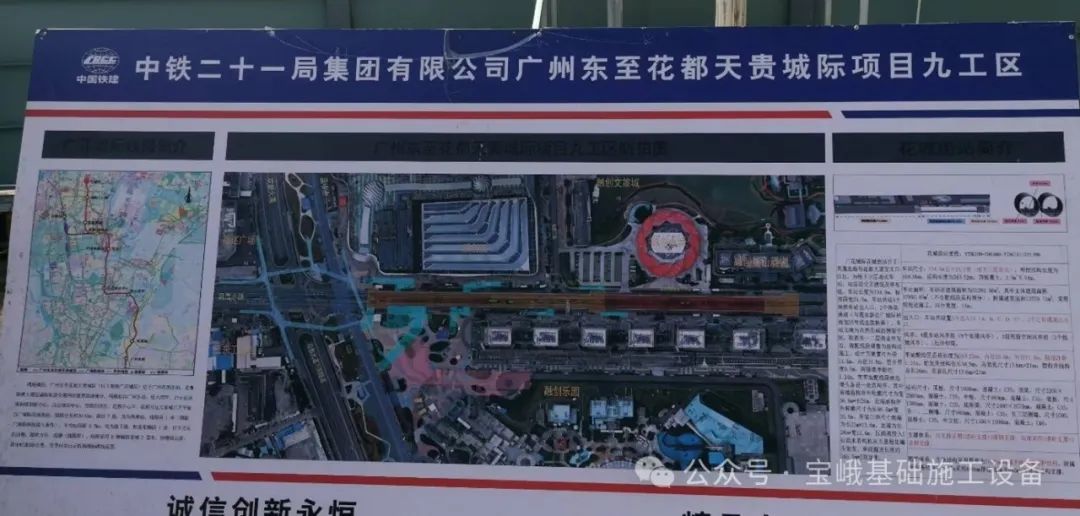

February 02, 2024End of 2023,It is contracted by China Railway 21 Bureau Group Co., Ltd.、Guangzhou Dong-Huadu Tiangui Intercity Railway Project professionally subcontracted by Fujian Ruiyuan Railway Construction Engineering Co., Ltd.(Short name“Guanghua intercity railway”)Huacheng Street Station Diaphragm Wall Project Completed Successfully。

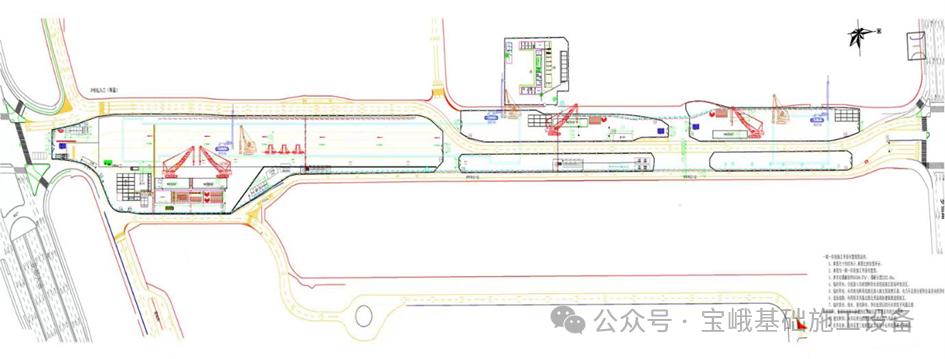

Huacheng Street Station is the terminal of Tiangui Intercity Station from Guangzhou East to Huadu.,Set parking line behind the station,It is an underground three-storey island platform station.。The station is located north of the intersection of Huadu Avenue and Fenghuang North Road.,Laid along the north-south direction of Fenghuang North Road。Total length of the station: 734.9 meters,Wherein the length of the open-cut part of the main body is about 469.38 meters,Standard section width 24.5 meters,It is a three-storey underground structure.,The main building area is about 37,777.26 square meters(Including open excavation of three layers at the south section and large mileage end、Excluding shield section)。

The foundation pit support scheme of this project adopts“1000 mm thick diaphragm wall+Vertical five-way support”Support form,The foundation pit depth of the standard section is 29.0 meters,The foundation pit of the end well is about 33.1 meter。Principle of embedded depth of diaphragm wall:Slightly weathered to 2m,Moderately weathered 3m,All、The highly weathered stratum shall be determined according to the calculation,The underground diaphragm wall in the karst cave area is deepened or at least a plain concrete diaphragm wall penetrates the karst cave and enters the bottom of the karst cave,No less than 1 meter into complete rock stratum or no less than 1 meter into stable aquiclude.5 meters,Concrete grade of diaphragm wall is underwater.C35(P8)。

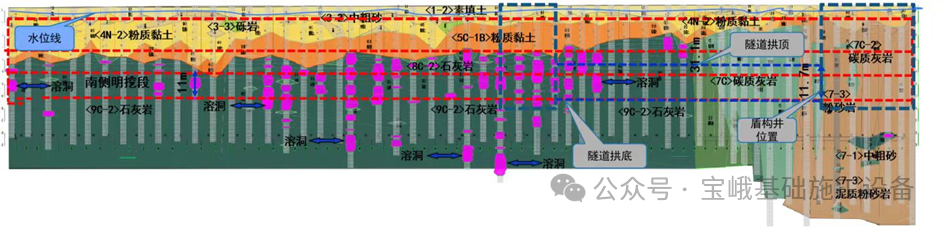

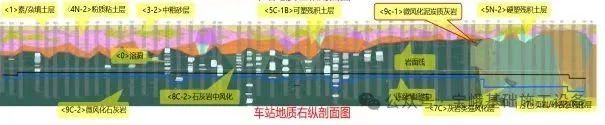

There are 205 diaphragm walls in the main body of the station.,Cubic meter of diaphragm wall is 3.More than 80000 square meters,Depth 32 m to 49 m。The geology of the station is as follows from top to bottom:Backfill、Plain fill、Medium coarse sand、Gravel sand、Weathered rock(It is dominated by limestone,And sandstone、Tuff、Carbonaceous limestone),The highest natural compressive strength of limestone is 116 MPa.。The underground continuous wall mainly adopts the I-steel joint type.,Double-wheel milling sleeve milling joint is adopted at the small mileage end,Locking pipe joint is set within the scope of large shield tunnel in the end section.。The construction of diaphragm wall structure is based on the site.、Pure milling is adopted for different geological conditions、The construction is carried out by combining a variety of combined processes such as grabbing and milling.。

The figure above is the geological section of the left line.

The figure above is the geological section of the left line.

The figure above is the geological section of the right line.

The project began construction on November 25, 2022.,However, due to the complex geological conditions,,And the station area is located in the karst development area.,There are karst caves of different sizes.,The rate of karst cave is 49%,The overall construction progress is slow.。To ensure the smooth progress of the project,,Fujian Ruiyuan Tieke Company quickly put in a Bao'e.BCS 125 slotting machine,It will reach the site in early March 2023.。

Bao'eBCS After the 125 slotting machine arrives at the site,,That is, start high-intensity construction.,Most of the time it is 24 hours of construction.,And the construction efficiency is significantly higher than expected.,With the first of slot 37“Full of knives”For example:BCS Milling 125 to 19.1 meter,Time used:5.1 hour;19.1m milled to 27.0 meters,Time used:4.8 hours,Average efficiency:1.65 meters/Hour;27.0 m milled to 32.1 meter,Time 2.4 hours,Average efficiency:2.17 meters/Hour;Finish one“Full of knives”Cumulative time:12.3 hours。

The picture above is from Bao'e.BCS Limestone milled by 125 slotting machine

The picture above is from Bao'e.BCS Limestone milled by 125 slotting machine

The diaphragm wall project was completed on December 5, 2023.,Within 9 months of construction,BCS 125 10 slots completed per month on average,In the meantime,Equipment operation is always efficient and stable,Running time of equipment exceeds 4,000 hours。

BCS 125 by slotting machine、Ynchronous pipe rolling system and main machine。The perfect combination of the three,So that that groove for speed of the double-wheel Milling Machine is high、The operation is simple and safe、Long service life and the like.。Bao'eBCS The total height of 125 double-wheel milling equipment is 32.39 meters,Working radius is only 4.84 meters,The total working weight is about 156 tons.,Capable of flexible operation in compact urban environment,It's in the noise、It has obvious advantages in fuel consumption.,In case of continuous loading of the item,BCS Fuel consumption of 125 is only 43-54 liters/Hour(About 48 on average.5 liters/Hour)。

BCS 125 inherits the excellent quality of Bao'e double-wheel milling,Application of Advanced Deviation Correction Technology,So that that verticality of the groove is more accurate;Excellent gearbox quality and strong cutting ability,It ensures the stability of construction.,It also ensures the efficiency of construction.。And that equipment is convenient to assemble and disassemble、The reliability is good、And that energy consumption is low、Low comprehensive operation cost,It can create higher value for users.。

BCS The maximum trench depth of 125 can reach 50m.。Precise Manufacturing of Core Components of Double Wheel Milling Cutter Holder,It can overcome the challenges brought by various complex formations to the failure rate and service life of equipment.。

Efficient construction is inseparable from sufficient power and excellent power conversion capacity.,Bao'e of the fourth national engineBCS 125 power up to 405 kW。Bao'e Double Wheel Milling machine applies the latest technology.,Optimize the design of hydraulic and electrical structures,While providing plenty of power,Minimizes fuel consumption。

Bao'eBCS 125 provides excellent safety and reliability,A series of operation auxiliary systems,Ergonomic design,Comfortable experience for operator。