Fast Intelligent New Factory: New Benchmark of Intelligent Factory in the Field of Automotive Transmission

February 27, 2024

At the beginning of the new year,In the new factory of Fast Gaozhi located in Xi'an High-tech Zone,Yellow industrial robots flexibly rotate their mechanical arms.,Accomplish all kinds of homework skillfully。Dozens of orange logistics cars shuttle back and forth.,Deliver all kinds of production materials in place accurately and orderly。All kinds of information charts and figures on the smart screen are constantly updated.,Production and operation dynamics at a glance。

New Factory of Fast Gaozhi,Shaanxi Fast Automotive Transmission Group Co., Ltd.“Fourteen five”Plan,Strategic Choice of Industrial Chain Layout around Innovation Chain,Enterprises are accelerating the transformation and upgrading of traditional manufacturing to intelligent manufacturing.,Complete the vivid practice of the strategic layout of the intelligent transmission system of a full range of commercial Vehicles.,Won the national intelligent manufacturing demonstration、The first batch in the country“Digital navigation”Enterprises and many other honors,It has become Shaanxi's equipment manufacturing industry to accelerate the integration and symbiosis of digital intelligence.、Promote the transformation of new and old kinetic energy.“Business card”。

The factory is based on“Industry 4.0”、“Intelligent manufacturing”Guided by the concept,Application of the new generation of information technology、Industrial Internet technology,Construct the integration of virtual and real、Data-driven、Interconnection of elements、Global traceability、Intelligent manufacturing system with full process automation,Successfully applied“Digital twins、Black light production、The Internet of Everything、Intelligent decision making、Green manufacturing、Data closed loop”Six core technologies,The manufacturing process is realized“Transparent、Black light、Number、Intelligence、Green、Lean”,Build intelligent production、Digital operation、New highland of networking management,Set up a new benchmark for smart factories in the field of automotive transmission。

01

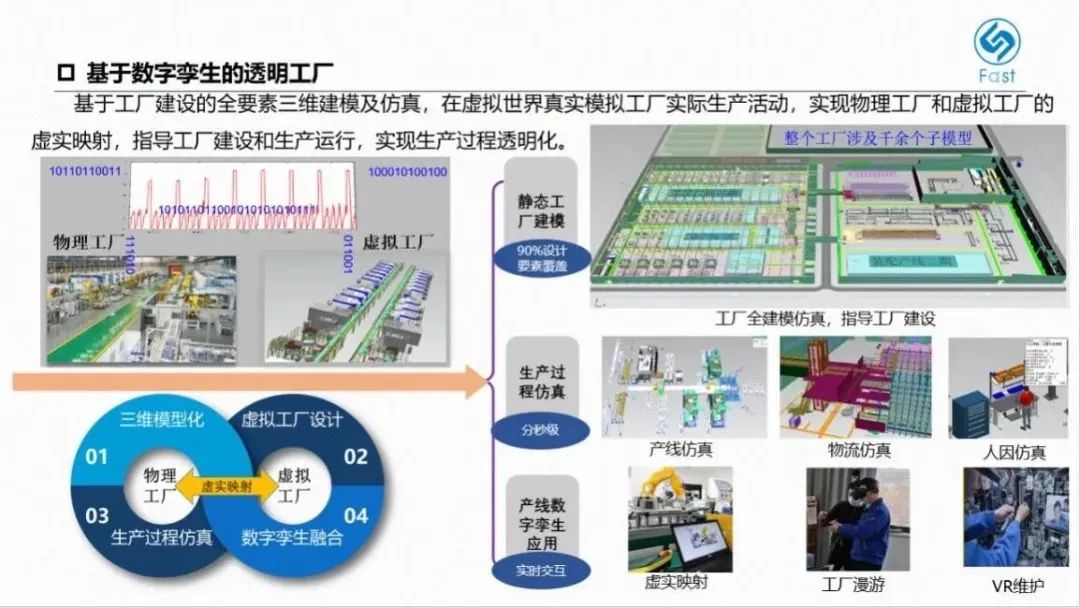

Transparent factory

The new factory of Fast Gaozhi uses a large number of industrial 4 applications such as modeling, simulation and digital twins..0 Key Core Technologies,Simulate the actual factory production activities in the virtual space,Implement interactive mapping between physical plant and virtual plant,So as to continuously optimize the plant layout.,Realize machining、Logistics、Rhythm verification and virtual debugging of production links such as assembly,And with the help ofARAnd other technical means,Make complex production processes more transparent。

02

Black light factory

The new factory of Fast Gaozhi is fully automated by machining.、Simplification of manpower production into principle,Build“Stabilization、Automation、Flexibility” Production line,The automation rate of machining reaches 100%,Assembly automation rate 70%Above,The operating rate of production line is 90%Above,And supplemented by“Intelligent logistics”、“The Internet of Everything”Support and“Intelligent decision making”Application、Information system scheduling,Finally, black lamp production is realized.。

03

Digital factory

Gaozhi New Factory is based on the construction of Internet of Things,With the help of 5GAnd other communication networking technologies,Will people、Machine、Material、Law、Ring、Measure、Seven production factors of energy,Collecting data through sensors and other sensing technologies,To realize the comprehensive digitalization of production factors、Interconnection。In the new factory of Gao Zhi.,Collect more than 100,000 pieces of data per second,The automatic acquisition rate and transmission rate of production data reach 100%。Realize 100 production factors%Identity management for、80%Data acquisition and 50%The control is issued。

04

Smart Factory

Gaozhi New Factory Promotes Intelligent Operation with Business Digitalization,Form an energy source、Lighting、Logistics、Production、Park、Operate、Seven Intelligent Scenarios of Equipment Maintenance,Realize the intelligent decision of the whole factory、Efficient operation。Through energy digitization、Visual operation monitoring,Realize automatic control of energy and power;Networking through lights,Realize personnel positioning and intelligent lighting;Automated scheduling through warehousing and logistics,Realize intelligent logistics;Through intelligent production scheduling、Task push and intelligent management of production factors,Realize intelligent production;ThroughBI、Technologies such as big data and cloud computing,Realize intelligent operation。

05

Green Factory

The new factory of Fast Gaozhi is always green.、Low carbon、Recycling is the direction of construction.,Photovoltaic power generation is adopted、Smart Energy Management、Green accessories、Green technology、Cycle packaging、Centralized processing、More than 30 advanced technologies such as recycling and reuse,Achieve low carbonization of energy auxiliary material、The production environment is friendly、Efficient utilization of resources、Waste disposal is harmless。Reaching annual carbon reduction of 7000 tons、More than 95% energy efficiency utilization%、PM2.5 up to“Excellent”Discharge、Three wastes treatment 100%Harmless,Effectively implement the national carbon emission reduction policy,Become a new business card of the industry。

06

Lean factory

Fast Gaozhi New Factory Continues to Increase Digital System Construction,System construction process、Production、Logistics、Quality four closed loop system,Global monitoring process,Accurate and continuous improvement,Build a lean factory。Process closed-loop opens up the data flow of R & D and production,Ensure transparent and controllable process execution;Closed-loop production through intelligent production scheduling、Process monitoring and element analysis,Realize fine management and control and whole process traceability;Logistics closed loop adopts intelligent warehouse management andAGVDispatch system,Realize automated logistics to drive production;Quality closed loop through total quality management,Real-time dynamic monitoring quality,Support quality analysis and improvement。

As the pioneer of digital transformation and upgrading in the field of commercial Vehicle transmission,Fast Gaozhi New Factory Gives Full Play to Comprehensive Perception Interconnection、Data-driven production、Whole process quality traceability and other advantages,Realize the transformation from traditional manufacturing to intelligent manufacturing,Increased productivity by 70 percent%Above,14% reduction in energy consumption%,The per capita output value increased by more than five times.。Fast Gaozhi's new factory covers a total area of 18..50,000 square meters,With annual outputAMTProduction capacity of 200,000 transmissions,The annual output value can reach 6.2 billion.。