Deji Machinery Co., Ltd.: Talking about the deep processing equipment and process flow of incoming materials in most asphalt mixing stations

March 20, 2024At present,With the rapid development of high-grade highway in our country,,Pavement construction equipment is also becoming highly specialized.,High standards,Continuous mass production,Intelligent and integrated development of various equipment,In the construction of asphalt pavement, asphalt mixing station is to ensure the quality of construction.,Improve efficiency,Key equipment with higher standard requirements。The equipment investment is the key part of the pavement construction technology in the domestic high-grade highway pavement construction.。

Efficiency of Asphalt Mixing Plant,And the quality of the mixture、The frequency, type and probability of failure of Asphalt Mixing Plant are related.,This paper analyzes and explains the reasons for the unqualified incoming materials of the asphalt mixing station, makes corresponding equipment solutions and provides the correct process flow.。

The first is the incoming information:Mineral material(The coarse aggregate making up the mixture、Fine aggregate and filler)Should be clean、Dry、No weathering、No impurities,And there are certain grading requirements.。Coarse aggregate(Gravel)It should also have sufficient strength.(Uch as diabase, Basalt ,Partially hard limestone),Wear resistance and oleophilic drainage,Have a good particle shape,It is advisable to use the corresponding equipment for crushing and processing relative to the stone.(Sand making machine,Vibrating screen,Powder remover and other crushing sand production line series equipment)。The skid-resistant surface layer is directly subjected to the repeated action of the Vehicle load,The coarse aggregate shall be harder.、Wear resistant、Good impact resistance and other index requirements。In the current construction project,According to the standards formulated by our country,The main technical indexes of coarse aggregate are controlled as follow:Crushing value>28%,Los Angeles Abrasion Loss>30%,Apparent density<2.50t/m3,Water absorption>2.0%,Adhesion of asphalt

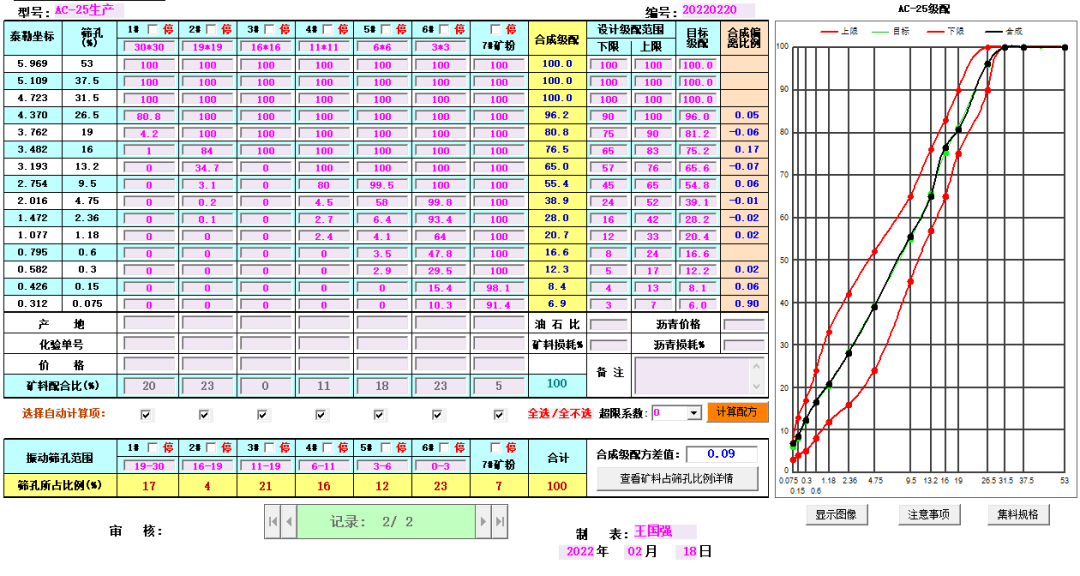

In view of the most important indicators of materials used in asphalt mixing station,Some of the indicators are inherent in the stone itself.,Or choose different materials suitable for laboratory and national standard requirements of stone.,Some indicators can only be achieved by equipment.,For example, the screening of each stone and sand specification,Required range of stone grading of various specifications,And sand(0-3mm)Fineness modulus requirements and sand(0-3mm)Whether the gradation is continuous and the rationality of the quality proportion interval,Content control of flaky and rod-like stones,The requirements for the granular type of high grade mixture and the requirements for environmental protection require the use of various equipment to achieve all the final requirements.。

2022,Respond to the call of the state,Combined with Deji Mechanical Double Carbon Target,This scheme is a station-type high-quality machine-made sand scheme.:

1.Seamless upgrade between conventional equipment and integrated raw material containerized deep Processing Equipment,Free switching;

2.Flexible modular system positioning design,Improve equipment interchangeability and scalability;

3.Diversified expansion,Multifunction:

1)Residue problem,The problem of material mixing,Gradation problem,The content of flaky rod exceeds the standard,The powder content exceeds the standard,Irregular shape of stone grains, etc.;

2)No dust leakage,And is more beneficial to that collection and the local use of the pow.;

3)Site binding upstream(Transportation and storage of incoming materials)And downstream(Asphalt station, etc)Seamless and smoother integration of sections;

4.Brand new plastic surgery+Sand making process flow scheme;

5.Brand new discharging and environmental protection dust collection structure,Better dust collection effect;

6.New finished product silo chute design,The structure is simpler,The cost is further reduced;

7.Lightweight design of the main building,The cost is further reduced;

8.Newly planned and designed discharge environmental protection dust collection structure,More efficient dust collection。