Energy saving and emission reduction, rush the construction period! The static drilling and rooting machine of Shanggong Machinery is very awesome this time!

March 29, 2024Construction of precast piles“Carry the handle”,

Low noise、The vibration is small、Energy saving and emission reduction,

Urban Pile Foundation“Environmental protection weapon”。

↓↓↓

Recently

In Shanghai Huahong HongliFAB2 Construction site of Phase I supporting project,Two sets of static drilling and rooting method machines shall keep their respective positions.,Synchronous construction,

Faced with the hard battle of racing against time,

To go deeper、More stable、More accurate combat stance down.“Take root”,

Build a solid foundation for Huahong Hongli Project。

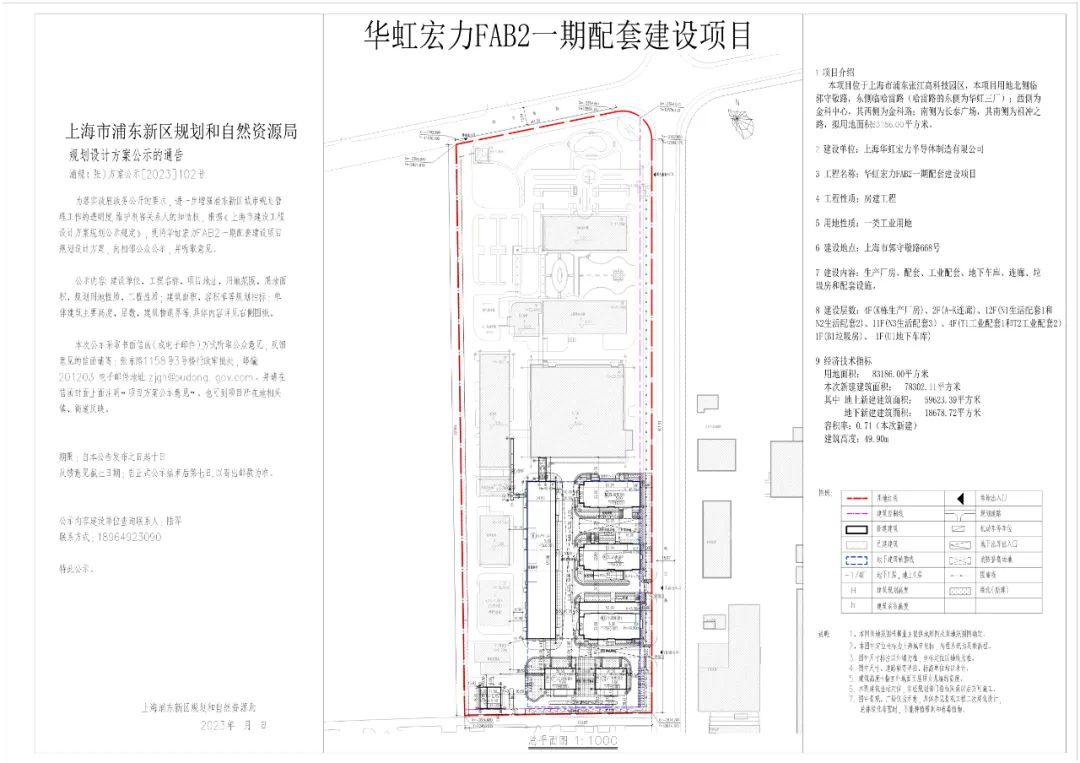

▲Video footage of project construction

Shanghai Huahong HongliFABThe first phase of the supporting project is located in Zhangjiang High-tech Park, Pudong New Area, Shanghai.,East to Halley Road,West to Jinke Center,South to Changtai Square,North to Guo Shoujing Road,The total land area of the project is 91896..16m2。The proposed project mainly constructs 3 dormitories.、1 workshop and 2 R & D buildings,The lower part is provided with an underground garage,And that underground of each single body is communicate with the outward expansion basement.。After the completion of the project,While greatly improving the living environment of Huahong Grace employees,,New construction of finished product test room,It will further enhance the operational efficiency and competitiveness of Huahong Hongli.。

▲Location of the project

▲Location of the project

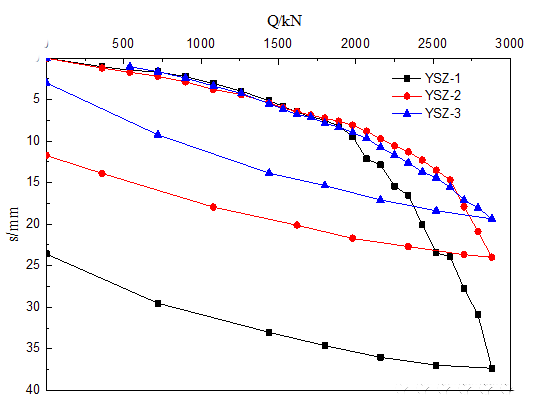

The pile foundation of this project is constructed by the method of static drilling and embedment.,The total quantity of embedded piles is 1298.,About 4.20,000 meters,Pile length 29-36m。Pile type shall be selected:PHC 500(100) AB C80+PHDC 550-400(95) AB-500/400 C80,Borehole diameter:650mm,Bore diameter:975mm,Bottom expansion height:2000mm。

▲Project plan

The site is adjacent to existing roads and buildings, and there are pipelines around the site.,Complicated environmental conditions,Possible deformation to foundation construction、More sensitive to vibration, etc.,Extremely high requirements for soil compaction in pile foundation construction,In close proximity to the building,Difficult working condition of on-site construction mud treatment,How to complete the project within 40 days,It has also become one of the difficulties in the pile foundation construction of the project.。

▲Project site

It is a green environmental protection pile foundation construction equipment independently developed by Shanggong Machinery.,SDP220HWith excellent product performance, the static drilling and rooting machine has become the first choice of the project side.。This product not only has a large torque,,The drilling depth is large,The reliability is good,And that construction efficiency is high,But also has that advantage of small vibration during construction,、Low noise、Energy saving and emission reduction, etc.。

▲SDP220HDuring the construction operation of the static drilling and rooting machineThere is speed、There is depth、Precision is right.SDP220HThe Best Interpretation of Static Drilling Rooting Machine,Two sets of equipment on site are used to form about 300 piles in a single daym,About 10-Construction efficiency of 12 piles,Ensure stable and efficient construction progress。

▲SDP220HDuring the construction operation of the static drilling and rooting machine

Excellent product,The market is never stingy with praise.。On-site operator feedback:“As an old handheld player for many years.,Shanggong MachinerySDP220HThe equipment torque of the static drilling rooting method machine is large、Power is strong、Drilling and underreaming are very efficient,The whole machine works reliably and stably.,It is an effective guarantee for project construction.。”

▲Pile material of static-drilling embedded pilot

▲Mud treatment for site construction

As the industry's leading provider of complete solutions for underground foundation construction,In recent years,Shanggong Machinery is continuously promoting the construction of core technologies.、Research and development of new products、Breakthroughs have been made in expanding market layout and other aspects.。

Future,Shanggong Machinery will continue to stand in the perspective of customers、Market perspective,Focus on creating differentiated core competitive advantages and products,Creatively meet customers' realistic and value needs,Lead the development of underground foundation construction industry。

Introduction of Static Drilling Grounding Method

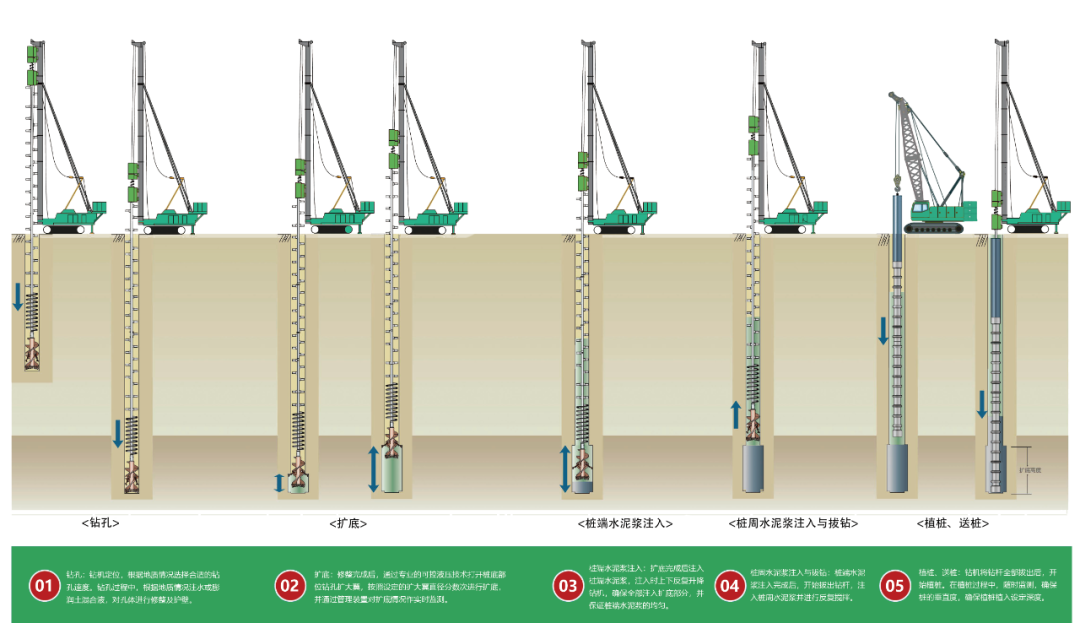

The static drilling and rooting method is to use the static drilling and rooting pile drilling machine to drill holes.、Whole course mixing and bottom expansion,Finally, the precast pile body is implanted.,Pretensioned prestressed concrete bamboo pile(PHDC)、Pretensioned prestressed concrete pipe pilot(PHC)、Prestressed concrete pipe pile with composite reinforcement(PRHC)Different specifications、Various combinations of models to meet design requirements,And press Drill、Reaming、Grouting、Pile foundation construction method for implantation and other processes。

Characteristics of construction method:

●No soil squeezing,No vibration,Low noise;

●And that pile quality is good,The elevation of pile top is fully controllable.;

●Very strong vertical compression resistance、Withdrawal and horizontal load resistance;

●And that discharge of the slurry is less;

●It has good social benefit and popularization value.。

Scope of application:

●Applicable to various seismic fortification intensity area,Adapt to the pile diameter:500-1200mm;●Cohesive soil、Silt、Sandy soil、Fill soil、Broken(Gravel)Stone, soil and geological conditions are complex.、There are many interlayers、Uneven weathering、Rock strata with large changes in hardness and softness,Maximum buried depth:90m; When the construction site is adjacent to a building(Structures)Or underground pipelines and other engineering facilities,Use other pile types,When adverse effects will be caused;●The top elevation of pile end bearing layer varies greatly.,When the length of the pile is difficult to determine accurately,The construction site is not available,Conditions for cast-in-place concrete or works in which the quality of cast-in-place concrete is not easily guaranteed;●Works with restrictions on the discharge of large quantities of slurry;●The design requires that the bearing capacity of a single pile is large.,When the technical and economic indicators and construction conditions are superior to those of other pile types.。

▲Construction process of static drilling embedded pile

SDPIntroduction of Static Drilling and Grounding Machine

SDPSeries of static drilling and rooting drilling rigs are the technical advantages of deep mixing drilling rigs developed by Shanggong Machinery Co., Ltd., which have been accumulated for many years,Completely independent research and development of a new generation of drilling rig products suitable for static drilling and rooting construction method。

Characteristics of construction method:

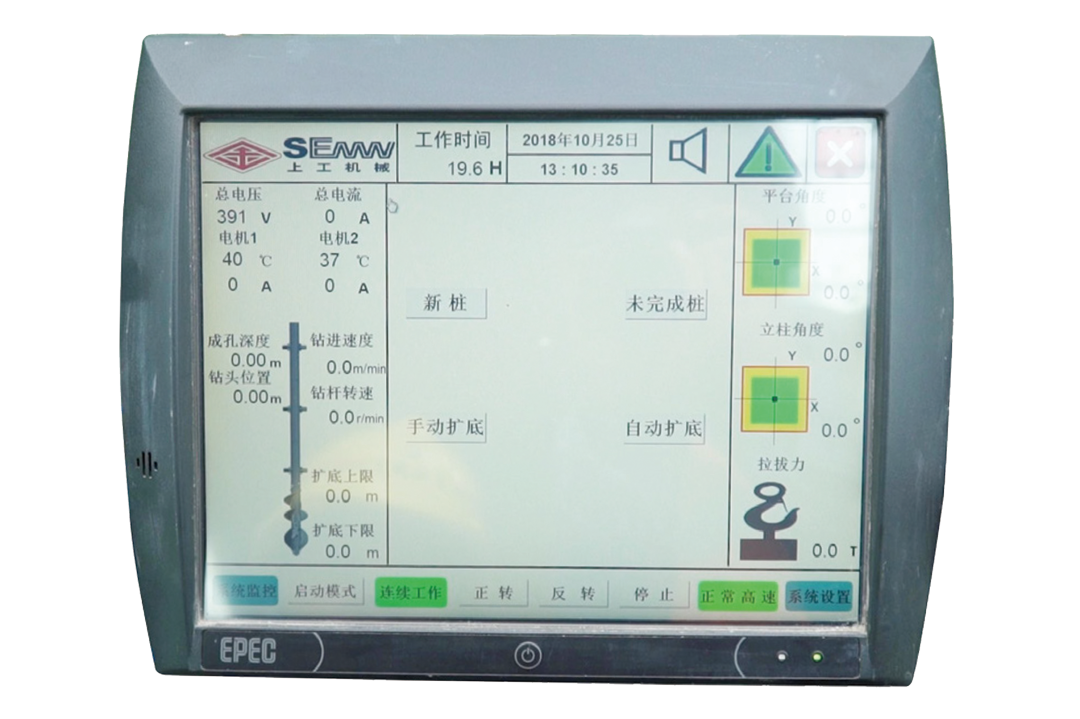

1.Adopt advanced hydraulic bottom expansion technology,The diameter of the underreaming is 1 of the diameter of the borehole-1.6 times,The bottom expansion height shall be 3 times of the borehole diameter.,And adopt advanced hypogynous machine software history data record way.,Record and analyze various data during construction,Forming a corresponding data curves。

2.Adopt intelligent construction management software,Intelligent touch screen mode is adopted for control,Real-time monitoring of construction process,Ensure the construction quality,All construction data are clearly reflected on the display and automatically stored.,It can be output and printed。

3.The operating system is provided with a power loss 380VAutomatic shutdown procedure,And ensure that that machine does not crash in the use process of the drilling machine,、A condition in which data is lost due to a power failure。4.The motor is started by soft start.,The soft starter itself has various motor protection functions.,Uch as undervoltage、Phase loss、Phase sequence、Overload and other protection。5.Reliable technical performance of hydraulic bottom expansion,Adopt hydraulic components with excellent quality,Make sure that at a depth of 80mDown,Normal operation of hydraulic bottom expansion。

Advantage of static-drilling embedded pilot

Low-noise drilling rig shall be used for static drilling of embedded piles.(Static drilling)、 The precast pile is completed by the embedment method(Pile planting)Pile foundation technology,It is a master of modern pile foundation technology.。After years of popularization and application,,It is green and environmentally friendly、Energy saving and emission reduction, etc “ many、Hurry up、OK、 Province "Its remarkable advantages have been highly recognized by all sectors of society.。

Characteristics of construction method:“many”●Through the use of bamboo piles、Combination of various pile types such as composite reinforced pile and enlarged bottom、Grouting technology,Reatly improving the compression resistance of the pile foundation、Pull-out resistance、Horizontal bearing capacity;●Applicable to various geological conditions,Pecially high load bearing、Pile foundation required by dynamic load。

“Hurry up”

●And that construction efficiency is high,Single machine can sink pile more than 300 meters per day,The economic benefit is higher than other pile types.;●Current through the rig,Change of bearing stratum can be detected,No pile cutting is required;●Optional and simple、Quick,Mechanical connection with reliable performance,Ensure the reliability of pile extension and the high efficiency of construction。

“OK”1.Factory prefabrication of pile materials,The quality is guaranteed;2.Construction by burying method,No soil squeezing,The pile body shall be free of damage;3.Intelligent construction,Equipment full-automatic monitoring,Ensure the construction quality; 4.Pile shaft and pile joint are protected by cement soil, And that corrosion resistance is improve;5.Green and environmental protection,It fundamentally solves the problem of slurry discharge in engineering construction.。

“Province”Compared with bored pile under the same condition:1.Water saving(Construction water saving 90%); 2.Energy saving(Construction energy saving 40%);3.Emission reduction(Slurry discharge reduced by 70%); 4.Time saving(Construction efficiency increased by 50 percent%);5.And that cost is save(Project cost saving 10%-20%); 6.Reduce carbon emissions by 50 percent%Above。

▲Pile material of static-drilling embedded pilot(Bamboo pile)

▲Pile material of static-drilling embedded pilot(Bamboo pile)

▲Construction site of static-drilling embedded pilot

▲Construction site of static-drilling embedded pilot