@ WTC, Liebherr Presents Innovative Tunnel Construction Technology in Shenzhen

April 24, 2024April 22, 2024,The focus of the global tunnel technology field is gathered at the World Exhibition Center in Shenzhen, China.,World Tunnel CongressWTC 2024 officially opens。At this conference,Liebherr Presents Large-Size Bearing Solutions Designed for Tunnel Applications。

As a leading partner in the tunnel construction industry,Liebherr has long been committed to innovation and sustainable development.。With more than 40 years of intensive cultivation in China,We are well aware of green development.、To realize the core role of carbon neutralization and intelligent manufacturing in the current transportation infrastructure construction。We have been actively exploring long-term and sustainable cooperation schemes.,To promote a win-win situation in the industry。At present, we provide a number of reliable solutions for many Chinese customers.。

/ Bearings for any application /

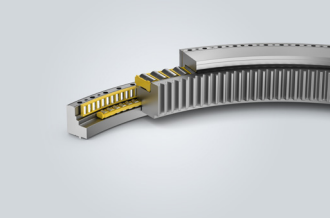

The main component of the TBM is a rotating cutting shield.,The second is the main bearing、Thrust system and tail support mechanism。Liebherr specializes inEPB、Large bearings designed for hard rock and other Shield Machine types cover internal tooth type、External tooth type and toothless type。These bearings can be up to 9 meters in diameter.,It has demonstrated its excellent performance in many metro projects.,Including Mumbai, India、London, England and Qingdao, China。

Main bearing

The main bearing serves to couple the cutter head to the thrust system,And bear all the load of the cutter head.,Ensure safe and continuous operation of equipment。So,Three-row cylindrical roller bearings are well suited for main bearings。As an alternative,Liebherr also offers a range of double row tapered roller bearings。

Erector bearing

Single-row four-point ball bearings and cross roller bearings are used to position the liner segments in the erector system。

/ Liebherr cooperates with famous customers in China /

Hand in hand,

Push the tunnel construction technology to a new height

Liebherr's tunnel Boring Machine for a well-known customer in China (TBM) Core bearing provided by the system,The tunnel construction technology has been pushed to a new height.。The diameter of this roller bearing is nearly 8 meters.,Weighing 44 tons.,It is a heavyweight product used in the largest tunnel Boring Machine at present.。It is also the largest Liebherr has produced to date.TBMMain bearing。The bearing is arranged on the cutter head part of the tunnel Boring Machine.,Allowing it to excavate huge tunnels up to six stories high.。This performance is achieved thanks to the twin roller design on the bearing raceway、Extremely accurate internal gear,And a system of 20 pinions driven by the inner ring。

Of course,We are capable of more than that.。In addition to the main bearings,Liebherr also manufactures erector bearings for the tunnel Boring Machine of this well-known domestic customer.,Its diameter is 7..3 meters,The weight is 5.7 tons。Although smaller in size compared to the main bearings,This kind of bearing plays a key role in tunnel construction.。It is installed at the rear of the cutter head.,Responsible for the accurate placement of precast concrete elements around the tunnel walls during the excavation of the tunnel。In the second step,The main function of these concrete elements is to provide curing and support for the newly excavated tunnel,To ensure the stability of the tunnel structure during the advance of the TBM。

Liebherr's main bearings will be validated in the tunnel Boring Machine project in Guangdong.。The tunnel is 8 kilometers long.,Height 15.5 meters,It will support three-lane double-deck traffic flow operation。As more and more cities around the world are renewing and expanding their infrastructure,,Yeah, the subway、Increasing demand for road tunnels。At the same time,Mining、Demand for hydropower and other tunnel systems is also steadily rising.。For Liebherr,Produce thisTBMMain bearings are part of the company's strategic direction.。Liebherr's cooperation with this prestigious client has led to the successful implementation of several such major projects.。

/ Focus on the needs of Chinese customers,Build localized production /

Liebherr Dalian New Parts Factory Completed

Liebherr has broken ground on its new plant in Dalian since 2021.,After three years of careful preparation,Finally, the grand opening on March 19, 2024.。The factory covers an area of 44,000 square meters,Total investment up to 1.100 million euros,It is one of the important production bases of Liebherr Group in Asia.。

This strengthens Liebherr's component products division,It has further expanded its global influence.。The factory has more than 250 employees.,The products mainly include the main bearing of Shield Machine.、Erector bearing、Wind power main bearing、Variable pitch/Yaw bearing and reducer。The new plant in Dalian will become one of the core production bases for Liebherr components.,And will further strengthen Liebherr's role inTBMInternational influence of the market。