Focus | Wittgen In-place Cold Recycling Double-layer Continuous Paving Technology Appears in Hunan National Highway Overhaul Project

May 17, 2024Recently,Wirtgen-based synchronous paving process W 380 CR The cold recycling fleet successfully applied the double-layer continuous paving technology of foam asphalt in-situ cold recycling and cement in-situ cold recycling to the national highway overhaul project in Hunan Province.。Previously, this new technology has been repaired in many national and provincial roads.(Click on the link to the previous issueLearn about specific application cases)And highway road maintenance.(Click on the link to the previous issueLearn about specific application cases)Successfully applied。This time in GAnother Successful Case of Maintenance of National Highway 234,Continue to promote green maintenance of national and provincial roads,It also provides more ideas for future road maintenance.。

In this project,Two sets W 380 CR Unit with Wirtgen Milling Machine,The double-layer cold regeneration of the asphalt surface layer and the water-stabilized base layer of the widened original pavement is synchronously completed by using the double-layer joint paving technology.,Integrally formed,Half-width operation up to 4.6 meters,Effectively shorten the construction period.,But also improves the road performance and the service life of the road surface.,It also shows the green and low carbon of Wittgen cold regeneration technology.、Sustainable solutions that are economical and environmentally friendly。

Project overview

Shuangfeng County, Loudi City, Hunan Province GNational Highway 234,It is an important regional economic trunk line in Hunan Province.。The pavement overhaul project is located at G234 K2324+394~K2327+Section 394,Due to increasing traffic loads and heavy Vehicles,And the erosion of natural disasters.,As a result, the asphalt pavement of this section was seriously damaged.,The main disease is longitudinal and transverse cracks.、Potholes, etc,Traffic quality and safety have been seriously affected.,Therefore, structural repairs are required to restore its roadworthiness.。

Repair plan

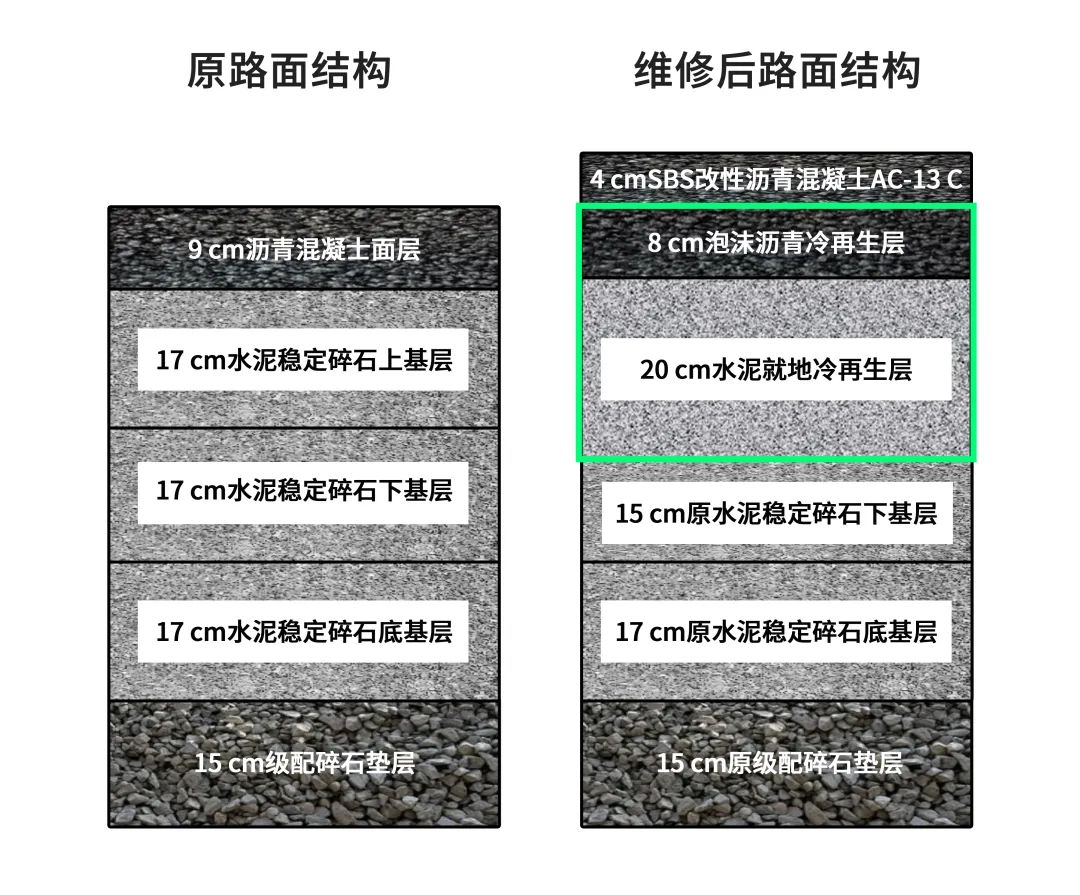

After detailed road condition investigation and detection in the early stage, it is shown that,The diseases of this section are concentrated in the upper base and asphalt surface.,According to the characteristics of the existing pavement structures、Current structural strength of pavement and traffic composition,In line with local conditions、Reasonable selection of materials、And is convenient for construction,And the active adoption of new technologies、Principles of the new process,The cold in-place recycling double-layer continuous paving technology is applied to the structural repair of the asphalt surface layer and the upper base of the original pavement。

Cold in-place recycling double-layer continuous paving technology based on synchronous paving process by WIRTGEN,The asphalt surface layer of the original pavement can be subjected to foam asphalt in-situ cold regeneration and the water-stabilized base course can be subjected to cement in-situ cold regeneration in turn,After the cold regeneration layer of the water stabilized base is compacted,(Before initial setting)Paving foam asphalt cold recycling mixture,So that that double-layer cold regeneration of the asphalt surface lay and the water-stabilized base layer of the original pavement is synchronously finis,Integrally formed。The technology combines the old cement stabilized material of the original pavement and the asphalt concrete material 100% Recycle and reuse in situ,It is in line with the national energy saving and emission reduction、Green and low-carbon industry development needs,But also reduces the lifting range of the pavement elevation caused by the overhaul of the traditional pavement as much as possible.。

The specific maintenance plan is as follow:Firstly, the asphalt layer of the original pavement is carried out 8 cm Cold in-situ regeneration of foamed asphalt,Followed by 20% of the raw water stabilized base course cm Cement cold in-place regeneration,Two layers of cold in-place recycling construction are carried out simultaneously,Keep fit together,After the end of the curing period, add 4 cm SBS Modified asphalt concrete AC-13C The upper layer of。

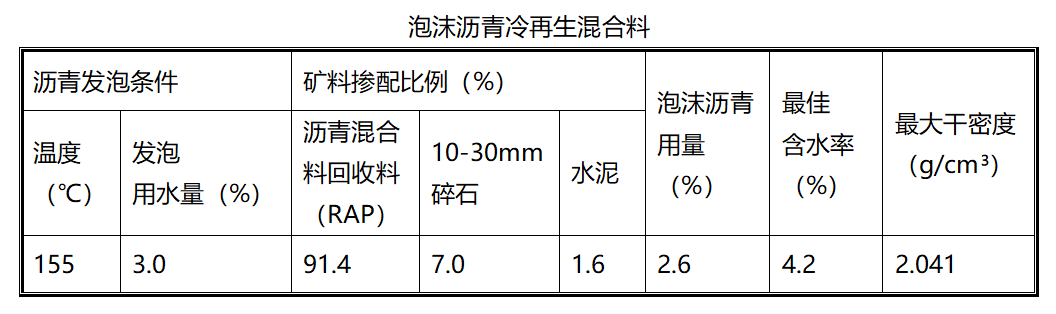

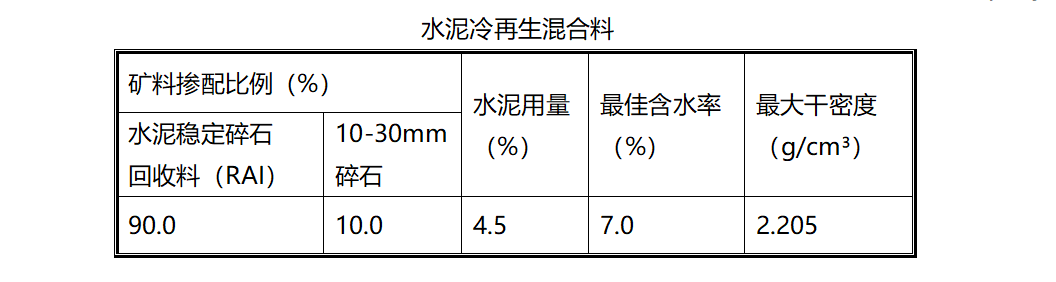

Mix design results:

Construction process of double-layer joint paving At one go

1.Cold in-situ regeneration of foamed asphalt

First,Using a synchronized chip sealer will require an additional 7% Gravel is spread on the original road surface。 Then ,Use a medium Wirtgen Milling MachineW 125 CF Forward the cold regeneration operation to the right 1.Pre-milling and planing the original asphalt surface course material with a width of 2m,The milling material is discharged to the remaining 3 of the half width by the conveying belt.Within 4 m width area(The half-width operation width is 4.6 meters);A powder spreader is then used.,The dosage will be 1.6% The cement is spread over the milled material and crushed stone.。

Later ,The first set W 380 CR The local cooling Recycling Machine unit makes the remaining width 3..4 meters,Milling and crushing the original asphalt surface material with a thickness of 9 cm,Mix in pre-milled material and spread chippings and cement,W 380 CR The cold recycler features an advanced spray system to bring the temperature up to 150℃ The base asphalt generates foamed asphalt.,And it and wat are precisely added into that cold recycle material,And finally mixing to form a uniform foam asphalt cold recycling mixture。While the cold recycled mix is passed through W 380 CR The conveying belt at the rear of the cold reGenerator is conveyed to the rear skip car for temporary storage。

2.Cement cold in-place regeneration

First,Use a medium Wirtgen Milling Machine W 125 CF Forward the cold regeneration operation to the right 1.Pre-milling and planing of raw water-stabilized base material with a width of 2m,Milling materials shall be unloaded on the top surface of half of the exposed cement stabilized base course by the conveying belt, and the remaining 3.Within 4 m width area(The half-width operation width is 4.6 meters); Then ,Use one aggregate spreader,Will need to add 10% The crushed stone is spread on the milling material.;A powder spreader is then used.,The dosage will be 4.5% The cement is spread over the milled material and crushed stone.。

Later ,The second set W 380 CR The local cooling Recycling Machine unit makes the remaining width 3..4 meters,20 thick Centimeters of raw water-stabilized base materials shall be milled and crushed.,Mix in pre-milled material and spread chippings and cement,At the same time, water is precisely metered into the cold recycling material,Mixing to form uniform cement cold regeneration mixture。While the cement cold recycling mixture passes through W 380 CR The conveyor belt at the rear of the cold recycler feeds the Paver hopper at the rear,Paving by Vogler Paver,It is compacted and formed by a Hummer full hydraulic single steel wheel roller and a rubber wheel roller.。

3.Paving foam asphalt cold recycling mixture

After the cement cold regeneration layer passes the compactness test,,Use another Vogler Paver to spread the foamed asphalt cold recycling mixture previously temporarily stored in the skip on the cement cold recycling layer.,Compaction is carried out by a Hummer fully hydraulic single drum roller and a rubber-tired roller。

Exchange and observe the industry's praise

The construction application of this new technology of green economy has also attracted the attention of all walks of life in the industry.。April 26,Sponsored by Hunan Provincial Highway Affairs Center、Undertaken by Loudi Highway Construction and Maintenance Center“On-site observation and technical exchange of new technology of cold in-place recycling double-layer continuous paving”Go,Provincial Highway Affairs Center and from all cities in the province、The leaders in charge of the State Highway Department and the heads of the departments went to the construction site to observe together. G234 construction of cold in-place recycling double-layer continuous paving,Indoor technical exchanges were conducted.。

Delegates at the meeting highly recognized this new maintenance technology.,It is considered that compared with the traditional maintenance scheme,,This technology can greatly reduce the need for new materials.,It can well control the lifting of pavement elevation after maintenance.,And that mechanization integration level is high.,The construction is efficient and fast,It is in line with the current green and low-carbon development concept.。At the same time,Delegates generally believe that this new technology will certainly promote the green and low-carbon transformation and development of Hunan's ordinary national and provincial roads.,And play an increasingly important role in the process of accelerating the pace of building a strong transportation country.。

Practical verification Taking into account environmental protection and economic benefits

As a professional pavement repair and upgrading solution,Cold in-place recycling double-layer continuous paving technology has the following advantages:

100% Asphalt surface course and wat stabilized base course material of cold recycle original pavement,The material is greatly saved,The environmental protection benefit is remarkable;

The in-situ cold recycling construction of the asphalt surface layer and the water-stabilized base layer of the original pavement is synchronously completed.,Common health preservation,It can effectively shorten the construction period.;

Double-layer cold regeneration integral forming,Interlayer connection ideal,The structure is continuous,And that integrity of the pavement structure is improve.;

The combination of foamed asphalt cold recycling layer and cement cold recycling layer optimizes the pavement structure.,Not only the grass-roots level has been strengthened.,And the foamed asphalt cold recycling layer can well prevent the generation of reflection cracks.,Therefore, the road surface has better road performance and longer service life.。