SANY Intelligent Compaction Assistant System — — Pavement Compaction Assistant

May 23, 2024Product positioning

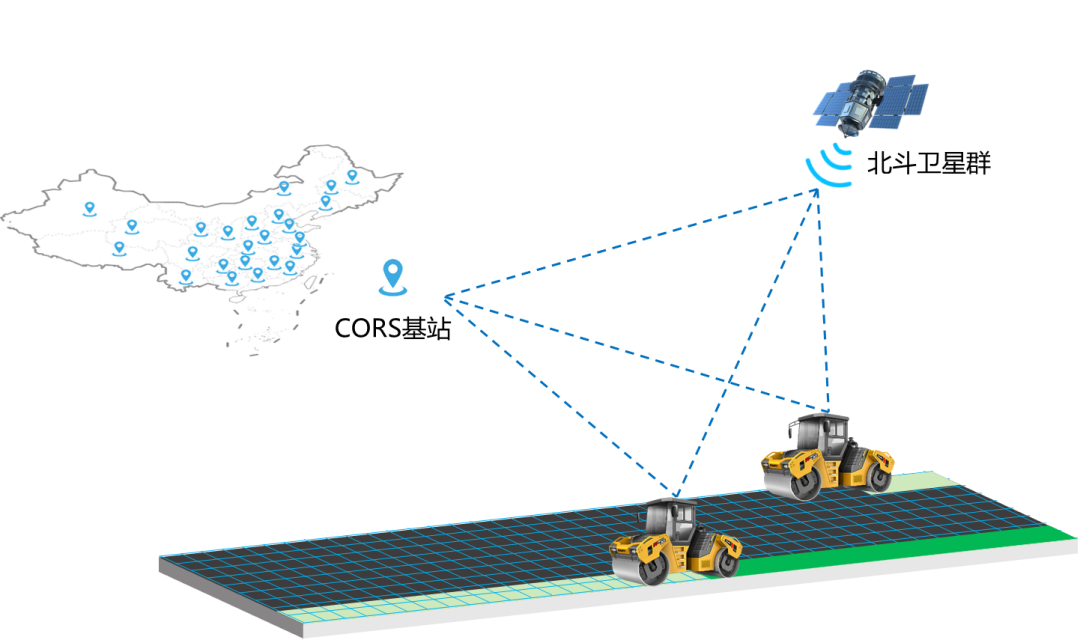

Intelligent compaction auxiliary systemAdoptCORSHigh precision positioning and advanced sensing technology,RealizationReal-time detection of rolling parametersAndVisual guidance,Instruct the driver to avoid overpressure、UndervoltageThe situation,Improve construction quality and efficiency。

Product selling point

1

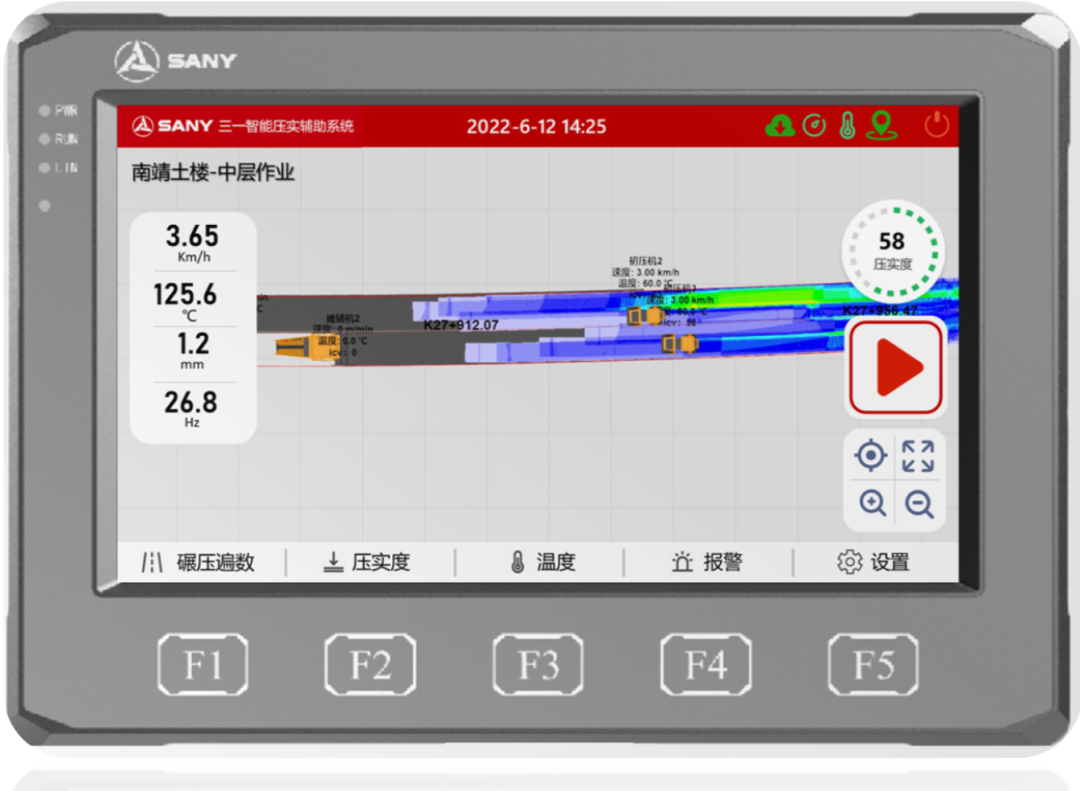

Real-time detection、Visual guidance

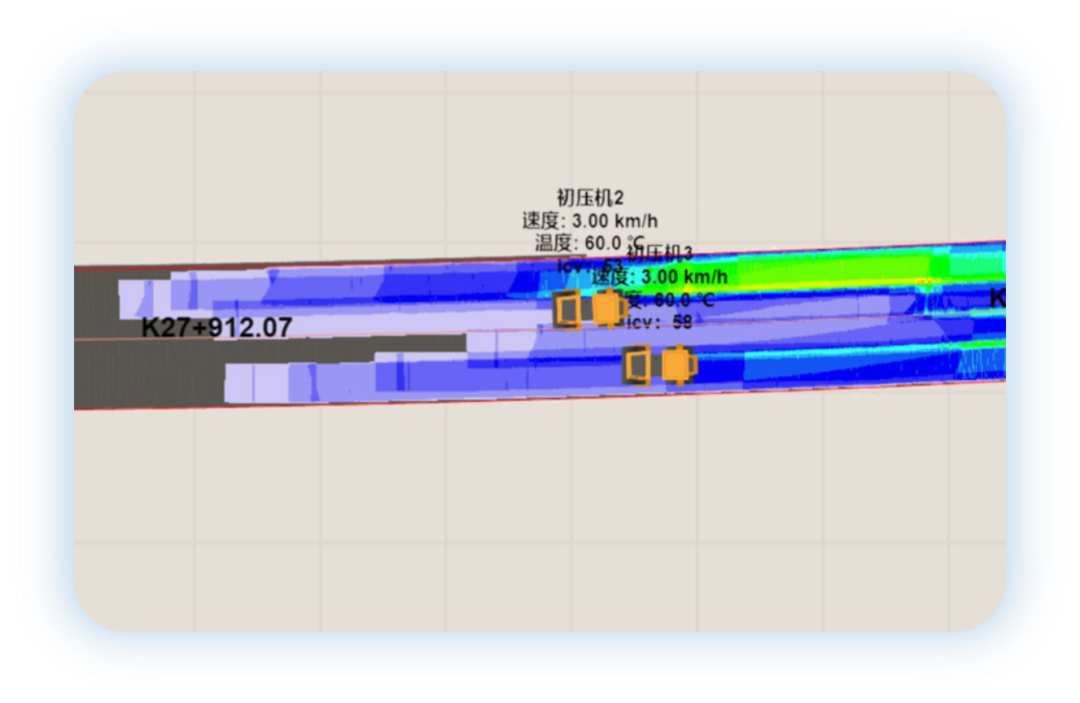

Industrial Vehicle-mounted computer records track of Road Roller in real time、Number of times、Compaction value、Temperature and other parameter information;

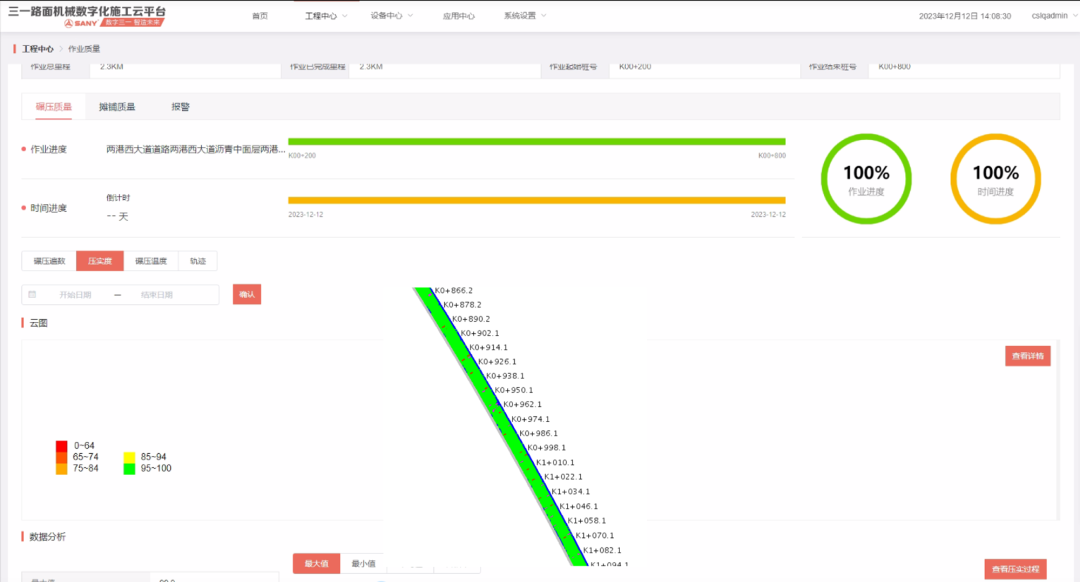

Graphical gradation maps present compaction quality information from different dimensions,Provide real-time navigation of quality information for Road Roller operators。

2

Process quality control

Real-time and accurate detection of relative compaction of pavementICV、Number of times of compaction、Temperature and other parameters,Master the quality of rolling process at any time;The platform automatically generates the construction progress report、Construction quality report and other information,Realize digital management of the whole process。

3

Precise management

AdoptCORSHigh precision positioning,Unifies compaction parameters and construction coordinate,Data sampling accuracy≤10cm;

Continuous inspection of construction quality,Replacing the traditional sampling inspection method of replacing surface with point,More comprehensive quality inspection。

4

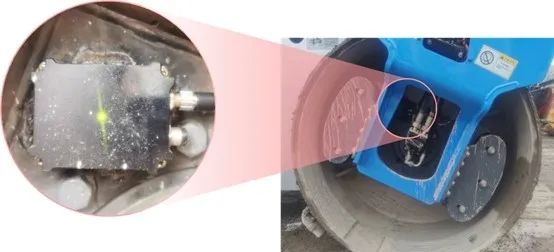

Flexible installation

The system adopts modular design.,Only external power interface is required,Enables quick installation;

It is not restricted by the brand of the main engine factory,Adaptable to various brands of Road Roller,Out of the box。

Technical features

1、Precise positioning

Centimeter scale is usedCORSPositioning technology,Positioning accuracy≤3cm,Operation coverage radius up to 20km;

Construction road gridding,Compaction data sampling accuracy≤10cm,Accurate positioning of weak areas。

2、Full time domain detection technique

Continuous measurement of compaction quality in full time domain,The compaction quality has been changed from post-inspection to operation process control.;

Ignificantly increase data sampling frequency,Test the sample≥10000 strip/km;

Combined with high-precision positioning technology,Achieve accurate statistics of rolling times,Statistical accuracy of compaction times>99.9%。

3、The cluster works together

Support for cluster operations,Real-time cloud uploading of cluster operation information,Real-time sharing of compaction quality data,Data collaboration management;

The on-board computer displays the position and track information of the aircraft group in real time.,Reduce the risk of safety accidents。

4、Visual guidance technology

Visual guidance technology,Real-time display of the relationship between roller position and quality,And is presented through a quality color scale diagram.;

ThroughICVCompaction value、Number of times of compaction、Dynamic display of three different dimensions of temperature,Compaction quality information at a glance。

5、Data platform technology

Adopt microservice architecture、Internet of Things、Big data and other advanced technologies,Through massive terminal data,Fully tap the value of data;

Real-time synchronization of construction data on the cloud,Check the progress of the project anytime and anywhere。

Economic value

Process quality improvement

Real-time on-line detection of compaction parameter,And display through a graphical color gradation diagram.,Construction quality is clear at a glance;For rolling weak area,Prompt the operator to supplement the pressure in time.(Or avoid re-rolling in the overpressure area),Effectively improve the quality of construction process。

Digital management

Continuous inspection of construction process quality,Quality data is stored in the cloud platform synchronously;Through massive terminal data analysis,Fully tap the value of data,Provide basis for quality traceability。

Reduce rework

And that compactness of the pavement is improve、Water seepage、Uniformity of structural depth and other parameters,Reduce rework caused by quality problems,Prolong the service life of road。

Reduce security risks

On-board automatic measurement mode is adopted,Reduce the safety risk brought by the process inspection of measuring personnel。

Application case

Technical parameters

|

Project |

Technical indicators |

|

Positioning accuracy |

Centimeter level |

|

Temperature detection |

0~200℃ |

|

Power |

15W |

|

Power source |

DC9-36V |

|

Environment |

-20~80℃ |

|

Working radius |

>20km |

Adapted model

Suitable for single drum roller、Double Steel Wheel Roller、Rubber-tired roller。