Shandong Lingong is the benchmark enterprise of digital transformation of manufacturing industry in Linyi City!

June 03, 2024In recent years,In-depth implementation in Linyi City“Thousands of technical reforms、Transformation of thousands of enterprises”“Gongfu Linyi·Beneficial Enterprise Action”And other special actions,Take the integration and development of new generation information technology and manufacturing industry as the main line of empowerment,Take intelligent manufacturing as the main direction of attack,Around the wood industry、Food、Machinery and equipment and other characteristic subdivision industries,Build“Small, fast, light and accurate”Solution,Guide enterprises“Zhi Gai Shu Zhuan”。

In order to implement the spirit of the provincial conference on high-quality development of digital economy,Summarize and exchange the experience and practice of intelligent transformation and digital transformation of Linyi manufacturing industry,Form a wide range of demonstration-driven effects,Promote more enterprises to achieve digital transformation and upgrading,The Municipal Bureau of Industry and Information Technology released typical cases of benchmarking enterprises in the digital transformation of manufacturing industry by stages.,Shandong temporary work is the first batch of excellent cases to show.。

Equipment on-line operation monitoring and fault diagnosis and prediction project

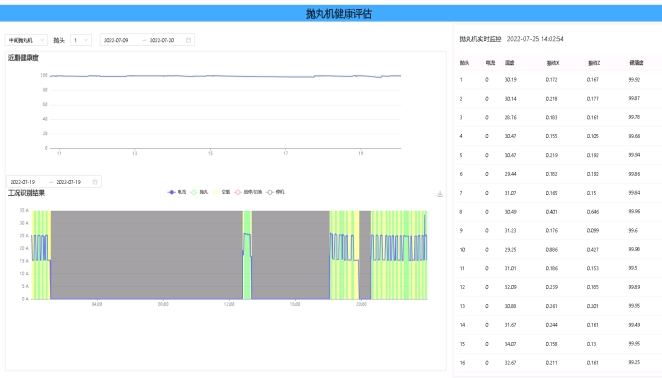

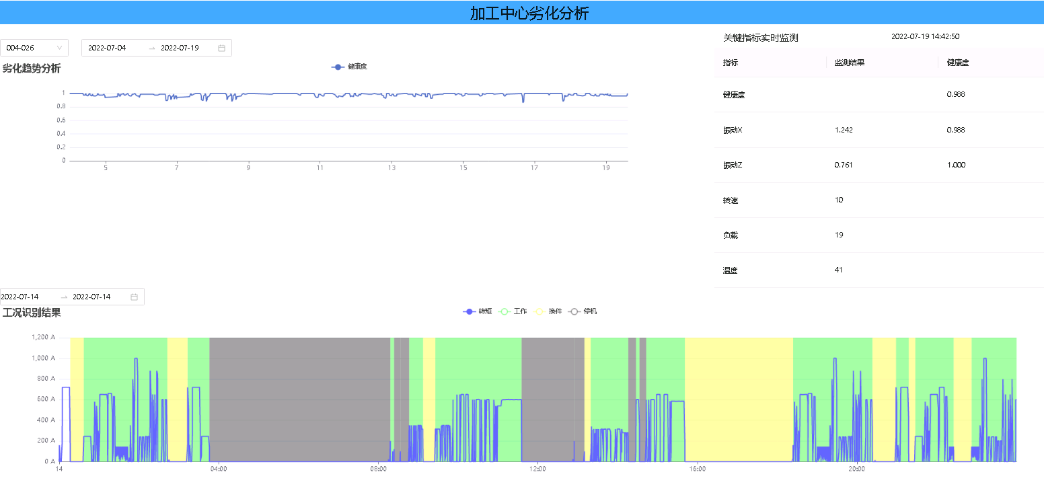

Machining Center、Shot Blasting Machine and welding robot are the key bottleneck equipment in large-scale production.,In case of equipment failure,Maintenance is difficult,Frequent maintenance will cause the production line to stop.,Affect product quality、Normal production of the workshop and even the whole factory,Bring great losses to the company。How to effectively monitor and diagnose the equipment,Find and troubleshoot equipment failures at the minor stage,Ensuring the highly reliable operation of bottleneck equipment is an inevitable demand to enhance the competitiveness of enterprise products.。

Solution

Joint expert team of Tsinghua University,Self-developed with Kunlun dataK2Assets-liteBased on the platform,Yes, machining center、Working status of Shot Blasting Machine and welding robot、Temperature、Vibration、 Electric current 、Pressure and other key parameters are analyzed.,Build an evaluation model for deterioration and health degree of key parameters of equipment,Train the model with a large number of sample data,Self-learning through model、Self-optimizing,Comprehensive assessment and real-time feedback of equipment key parameter deterioration and health condition,Guide preventive maintenance of equipment,Ensure that the equipment is always in the best working condition。

Figure 1 Health Assessment of Shot Blasting Machine

Figure 2 Machining Center Deterioration Analysis

Achieve results

Through information and digital construction,The company has achieved the following results:

1、Reduce the number of equipment failures by 40%,Reduce MTTR 30%,Timely maintenance rate increased by 20 percent%,10% increase in equipment utilization%。

2、The visualization and informatization of the production process are realized.,It can reduce the loss of failure line by 1.55 million yuan./Year,And that production cost is reduce.。

3、And that qualification rate of the product is improved.,Increase the qualification rate of structural parts by 3 percent%。

Fig. 3 Field application of Shot Blasting Machine

Fig. 4 Field application of welding robot