From Foshan to the World: Aiming at Customized Walking Mechanism, How Yonglitai Writes Industry Legend in 1967

July 08, 2024Foreword:

As a rare enterprise in the field of trailer running mechanism in China in the new era, it has gone through Jiazi.,To this day,Yonglitai, which is constantly transforming and moving forward, has been deeply engaged in customizing axles for more than 60 years.,User-centric、Customized axles as the core,Striding forward on the road of innovation。

The story of it,Shiwan Hardware Machinery Repair Factory, which started in 1957,But a true legend.,From the beginning of restructuring and separation in 2005……

Come into being with the trend Break the monopoly of foreign technology

First half of 1957,Under the tide of socialist transformation of handicraft industry and capitalist industry and commerce in New China,It is the predecessor of Yonglitai——The Shiwan Hardware Machinery Repair Factory, which was established on the basis of Shiwan Daily Sundries Society, was born.,The journey of Jiazi set sail in 1967.。

1957-40 years in 1997,From the ship nail、Simple equipment repair,To the mud cutter、Ball mill、Crusher、Production of large equipment such as mud screening machine,In the special historical period when China's trailer axle industry has not yet fully started.,Yonglitai is constantly carrying out system reform and independent technology exploration.,Enterprises are also related to the state、Along with the times,Innovate and move forward in groping。

It is precisely because of the sharpening and tempering of this special era.,At the beginning of its establishment, Yonglitai was faced with a variety of products.、The complex situation of customization demand,It also lays a good foundation for enterprises to adapt to more flexible external environment and customized market demand.。This group of backbone forces grew up under the state-owned system.,Set up indomitable for Yonglitai、The indomitable spirit of craftsmen,This spirit still occupies an important position in Yonglitai's corporate culture today.,And continue to advance、Sublimation。

Late 1990s,Fotao Group Litai Ceramic Machine is transporting its hydraulic automatic brick press.、Automatic turnover machine and other large equipment and precision instruments.,Often faced with Vehicle/ 'target='_blank' style='color:blue;'>Transport Vehicle axle fracture、Poor stability and the like.,In order to better improve service efficiency,It is urgent to develop an axle more suitable for heavy and precision instrument Vehicle/ 'target='_blank' style='color:blue;'>Transport Vehicles in the Chinese market.。

June 2001,Litai Ceramic Machinery General Factory was renamed Litai Machinery;July of the same year“Foshan Litai Ceramic Machinery Engineering Technology Research and Development Center”Set up,Axle orientation research and development officially on the right track。

At the beginning of the new jubilee,Domestic precision instruments and heavy equipment axles mostly rely on imports.,In order to further break the technological monopoly,,Litai Machinery takes its own equipment transportation as the starting point.,In-depth study of various transport conditions,Targeted research is carried out in combination with the concentrated force of goods.,China's largest automatic brick press for beam-column structure in Litai Machinery、Carry out road test for transportation of heavy goods such as polishing machine。

After six years of trial and error and technical demonstration,,March 2002,Litai MachineryLTSeries semi-trailer axles formally put into production,It has passed the authoritative certification of the national quality supervision and inspection institutions.。

With excellent product quality,Li TaiLTAs soon as the series trailer axles are introduced to the market,“Be an instant hit”,In 2004, the daily output of Litai mechanical trailer axles increased from 30 at the beginning to 100 at the end of the year.,Annual output exceeded 1.60,000,It is not only in the forefront of the domestic trailer axle industry.,And obtained the first batch of foreign trade business license.,Products began to gradually move to Southeast Asia.、North America、Markets such as the Middle East and Australia。

With Litai Axle becoming the second largest main product of the Group,For better professional development,November 2005,The first shareholders' meeting of Yonglitai Company was held in Foshan。December 1 of the same year,Foshan Yonglitai Axle Co., Ltd(Hereinafter referred to as“Yonglitai”)Officially operate independently。

Focus on customization High-quality solutions to industry pain points

Relying on its own manufacturing capacity of large-scale equipment and precision instruments,Yonglitai combines market demand and constantly brings forth new ideas。

May 2005,Yonglitai's new generation of axles overcomes the huge volume of equipment、Difficult problems such as complex road conditions will be successful.YPTransportation of 7200 brick press to the 19th China International Ceramic Industry Fair,It became the only brick press exhibited in the exhibition in kind.,It has attracted much attention in the industry。

Second half of 2005,Sudden Change of Transportation Market Competition Pattern in Daqing Oilfield,Lightweight axles become the market“New favorite”。Safety is the top priority in the transportation of dangerous chemicals,How to reduce the cost of lightweight axles while taking into account the safety of Vehicles has become a dilemma faced by all trailer axle enterprises.,Yonglitai, who is far away from Foshan on the coast of the South China Sea, took the lead in handing in the answer sheet.。

At that time, the brake system specification of all 13-ton trailer drum brake axles on the market was 420.×180mm,Yonglitai is bold and innovative,While taking full account of axle weight reduction,Further optimize the axle tube material、Core configurations such as brake linings,For the first time in the semi-trailer axle industry, the brake system specification of the 13-ton drum brake axle was upgraded to 420 for the 16-ton drum brake axle.×220mm。

Yonglitai named this new lightweight axle specially designed for dangerous chemicals tankers asLTD14F11 series,It has not only opened up a brand new product series of 14 tons of trailer axles in China,,And once it came out, it triggered the industry's enthusiasm.,And establish Yonglitai's market position in the field of lightweight axles at one stroke.。LTD14FThe first battle of 11 series products became famous.,Also let a domestic large Vehicle/ 'target='_blank' style='color:blue;'>Transport Vehicle leading enterprises take the initiative to extend the olive branch.。

At that time, the axle cars used in Shanghai Port had high bearing requirements, and the conventional axles were difficult to meet.,Therefore, all of them adopt imported rigid suspension.,Not only the price is high, but also the after-sales service is unsatisfactory.。

Early 2006,The other side seeks cooperation with a try attitude.,Jointly explore the localization of rigid suspension。After six months of joint technical research,,Yonglitai Rigid Suspension is officially launched,Not only break the monopoly of overseas technology at one stroke,And that structure is compact,Maintenance is simple,The bearing capacity is strong,Tailored for low load bearing surface and low center of gravity of port terminal Vehicle/ 'target='_blank' style='color:blue;'>Transport Vehicles。

Take the opportunity of solving customized transport scenarios,Since 2006, Yonglitai has been exploring new technologies and new ways of trailer axle application in both domestic and international markets.,Products cover single point suspension、Rigid and mechanical suspension,It has accumulated rich experience in the application field of German and American axles.。

Efficient collaboration Establish a one-stop customized support system

2007,For the needs of the European export market,Yonglitai became the first batch of domestic axle brands to study disc brake suspension in the Chinese market.。In 2010, Yonglitai successfully developed the first generation of air suspension disc brake.,It has been verified by overseas markets for many years.,New edition as early as 2017GBBefore the implementation of 7258 new regulations, Yonglitai Air Suspension has completed five generations of product iteration upgrades.,Product from the original improved version、Heavy duty、Lightweight to the latest generation of new beam series,Realization“R & D generation、Transforming a generation、Reserve generation”Sustainable development,More than 30 independent patented technologies have been formed.,Take the leadDB44《Technical specifications for air suspension assembly of trailer》And other standard drafting,Continuously lead the innovation of domestic air suspension technology。

With“Craft+Custom technology”It is the ability base,Vertical integration and efficient synergy based on forging, casting and system solutions,Yonglitai works hard on internal skills、Take the initiative to change,On the one hand, it actively introduces capital to integrate resources.,On the other hand, strengthen the lean management of enterprises to improve operational efficiency。

2012、In 2013, Yonglitai won the bid for major national export projects for two consecutive years.,It took only one month from receiving the order to completing the installation.。To complete the delivery with high quality,Yonglitai overcomes many difficulties,24-hour multi-department collaboration,The parts were packed to the trailer enterprise site and assembled by a special person, and finally the delivery was successfully completed.。

2018,The first self-developed automation line in the domestic axle industry was built in Yonglitai,New Automatic Axle Tube Extrusion Line、Intelligent stepping heat treatment production line and shaft body automatic machine plus welding line,It not only subverts the production process of traditional axles,,The efficient combination of production processes and online automatic detection are realized.,And in the intelligent transformation four years later,ERP 、MESAndWMSSystem and other effective links,Complete the perfect transformation from manufacturing to intelligent manufacturing。

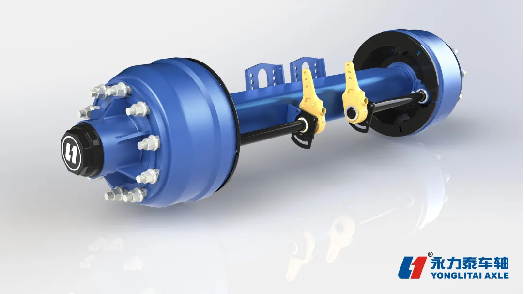

Axle customization as the core,Today, Yonglitai has established research and development from design.,Manufacturing、Test and verify the whole process service system to maintain the whole product life cycle in the post-market.,It has built a rare first-class testing and testing capability in the industry.,Covers axle fatigue testing、Axle braking performance test、Five-channel electrohydraulic servo trail chassis test stand、Spectrum analyzer and other detection and test capabilities,And with the industry mainstream liquid tanker.、Barn car、Flat car、Leading enterprises of engineering Vehicles and other special Vehicles have reached strategic cooperation,Achieve joint development,Modular supply。

In 2023, Hubei Yonglitai Factory was officially put into operation.,Yonglitai has not only become the first enterprise in the axle industry to form a dual pattern of north-south factories.,But also has the ability to reform from materials.、Extrusion molding、Heat treatment、Machining、Self-made processing capability of the whole process from surface treatment to assembly,The hub is realized、Brake drum、Customized R & D and manufacturing of shaft tube and other parts。

Outlook:To custom cast quality·Promoting sustainable development in the transport sector

Canghai crosscurrent shows the mainstay,Look at the main peak of the majestic mountains。Adhere to“Wisdom is on the axis·Customized accompanying”Product concept,As the first domestic axle brand,Yonglitai is China's semi-trailer axle industry from scratch.,From existence to refinement,Witness from the refined to the new、Participants and leaders。67 years later,Standing at the starting point of a new journey,Across the years,Still cast fine works with ingenuity,Customization wins reputation,Continuous deep cultivation of products、Three customization areas of working condition and service,To become“World leader in trailer undercarriage solutions”Strive for this corporate vision.。