Gini: Sharing on Leasing Operation Management (VII)-Service Excellence: How to Manage Fleet Service Well?

September 02, 2024If you want to be ahead of the other competitors in the long distance race of this wise man.,What are the requirements??What aspects should we pay attention to??

In the last issue, we introduced why we should do a good job in fleet service management.,Some may ask.,Of course I know that fleet service management is important.,But the company has limited resources in the process of development.,Lack of experience,How can we really pull the maintenance service management to a higher level??

Next, I will elaborate some important parts of successful service management from four aspects.。Today we will focus on it. “ How Security Affects Service Management” And “Preventive maintenance” These two topics.。

|

1 |

How Security Affects Service Management |

|

2 |

Preventive maintenance is the key to keeping equipment in good condition. |

|

3 |

Implement lean management |

|

4 |

The support of manufacturers is crucial to the development of leasing companies. |

1. Safety comes first

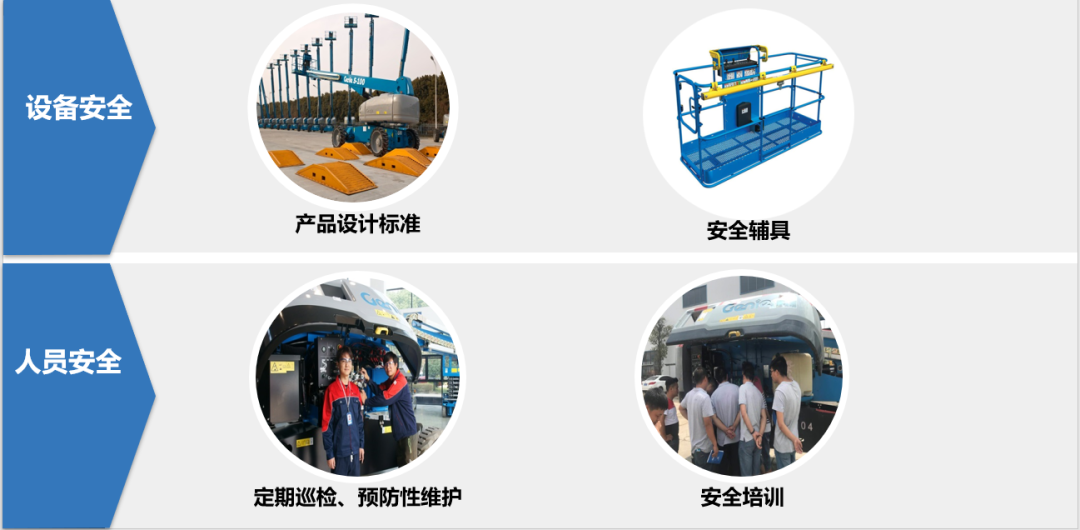

Safety is the lifeline of the aerial work platform industry.,Nothing is possible without security.。Security involves two parts.:On the one hand, the device itself,On the other hand, personnel。

The device itself is safe: Assured by manufacturer's design and through industry certification standards。In addition, the development of security options,For example, Genie's Safety Fall Arrest Kit、Anti-collision safety device for operator head and alarm device for operator contact。All these have played a very good role in protecting the safety of operators.。

About personnel safety,The safety training of operators and service personnel should focus on practical results and cultivate safety awareness.。Additional regular safety training for service personnel,Like a high-altitude Vehicle loading and unloading,Hoisting,Work at height,Tag and lock,Fatigue management and so on.。Remind the service personnel to carry out the operation environment assessment every day.,Suspend operation in case of danger。In addition,All operational and safety training must be documented。

In addition, it is necessary to pay attention to equipment safety inspection in fleet service management.,Regular walkdown and preventive maintenance of field equipment safety devices is essential。Safety inspection is to prevent customers from shielding safety devices and illegal operations.,Prevention of safety accidents。According to Hain's law,Behind every serious safety accident,There must have been 29 minor accidents and 300 near misses and 1.,000 accident hazards。Because the cost of dealing with security incidents is very high and very troublesome.,So our goal is zero damage.。

2. Preventive maintenance is key

Before we talk about preventive maintenance.,Let's look at a real case first.:A leasing company has an EFI diesel engine with three national emissions reported for repair.,Unable to operate after normal starting,On-site inspection shows that the oil-water separator has not been discharged normally and replaced regularly.,As a result, water enters the fuel injection nozzle and causes the fuel injection nozzle to rust.,The fuel injection nozzle and the water separator element must be replaced,The whole maintenance cost more than 10,000 RMB.,And down for days.。Can we prevent this from happening??This leads to the concept of preventive maintenance.!

So what is preventive maintenance??It is the completion of periodic and routine maintenance or replacement of spare parts before equipment failure occurs.,To help keep the aerial Vehicle running normally.,Prevent any unplanned downtime for maintenance and the expansion of damage caused by unexpected equipment failure,Ultimately, it is to reduce maintenance costs.。If the rental company has preventive maintenance on the equipment,In the above case, the above problem can be avoided by regular drainage of the oil-water separator and replacement of the oil-water separator filter element.,The cost is only the cost of an oil-water separator and patrol.。It can be said that preventive maintenance runs through the whole life cycle of equipment.。

Preventative maintenance includes more than routine maintenance of equipment.,It needs to archive every inspection and maintenance record.。These records can help maintenance personnel predict the appropriate time for replacement of spare parts.,It also provides reference for fault diagnosis.。As a manufacturer,We believe in preventive maintenance,Guide and promote the management and service personnel of the leasing company to attach importance to and implement this maintenance method.,This saves maintenance costs.,Ensure long-term stable operation of the machine。In addition, Gini has launched a comprehensive maintenance guide for boom and scissor AeriaL Work Platforms.,This is a good preventive maintenance instruction manual.,Saves time and repair costs for rental companies,And the service life of the machine is prolonged.。